TM 5-3895-359-14&P

11. With the exhaust valves installed in the cylinder

5. Install the valve guide oil seals on the valve guides

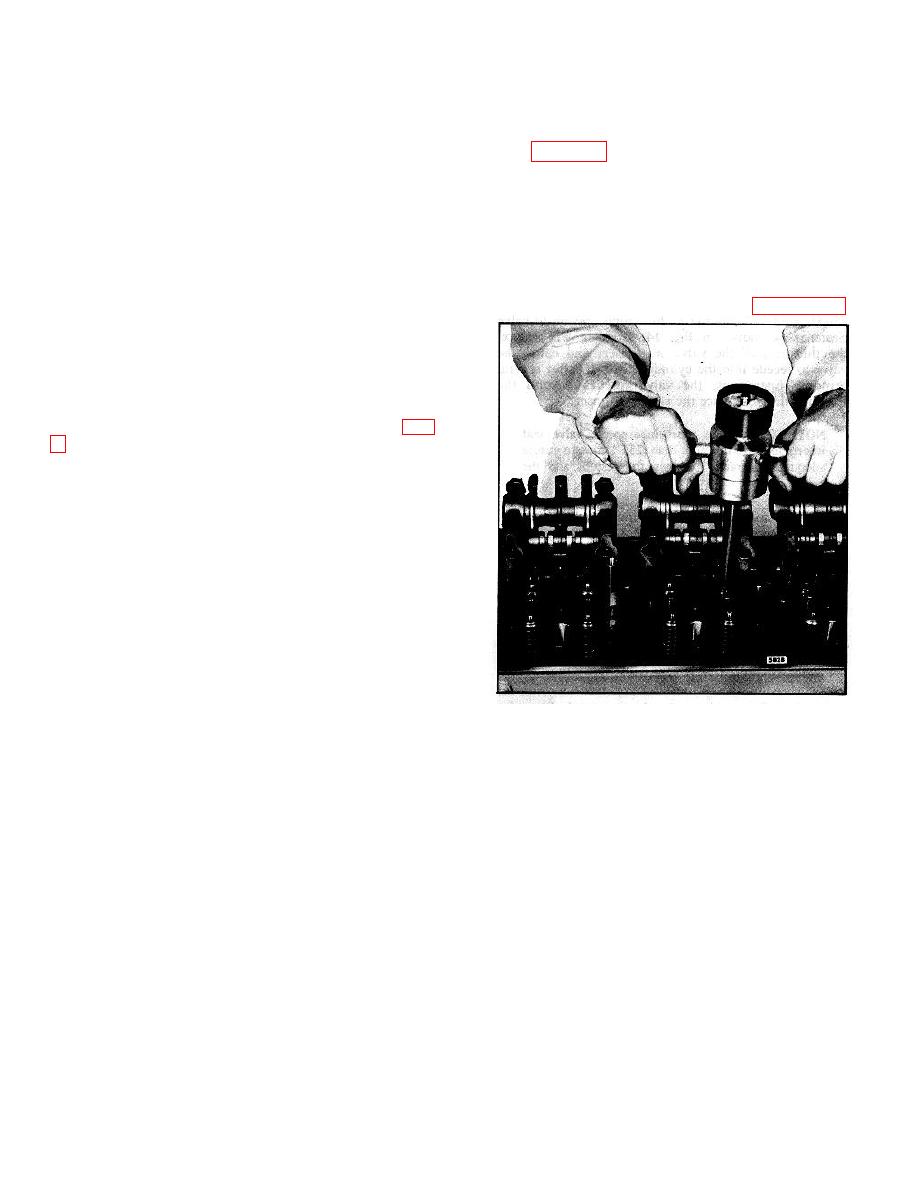

head, use spring checking gage J 25076-01 and note

as follows:

the gage reading the moment the exhaust valve starts to

open (Fig. 16). The minimum allowable pressure

a. Place the plastic seal installation cap on the end

required to start to open the exhaust valve must not be

of the valve stem. If the cap extends more than

less than 15 pounds (67 N).

1/16 " below the groove on the valve stem,

remove the cap and cut off the excess length.

12. Install the injectors, rocker arms, shafts, brackets

and any other parts previously removed from the

b. Lubricate the installation cap and start the seal

cylinder head.

carefully over the valve stem. Push the seal

down slowly until it rests on top of the valve

13. Install the cylinder head. Refer to Pre-Installation

guide.

Inspection and Install Cylinder Head on Page 10-2-25.

c. Remove the installation cap.

6. Install the valve springs and valve spring caps.

7. Thread the valve spring compressor J 7455 into one

of the rocker shaft bolt holes in the cylinder head (Fig.

8. Apply pressure to the free end of the tool to

compress the valve spring and install the two-piece

tapered valve lock. Exercise care to avoid scoring the

valve stem with the valve cap when compressing the

spring.

NOTE:

Compress the valve spring only

enough to permit installation of the

valve locks. Compressing the spring

too far may result in damage to the

oil seal.

9. Release the tool and install the valve locks on the

Fig. 16. Checking Pressure Required to Open the

remaining exhaust valves in the same manner.

Exhaust Valve in Cylinder Head

10. Check the position of the exhaust valves (Fig. 14).

Support the cylinder head at each end with wood blocks

and remove the masking tape so that the exhaust

valves are free. Then give the end of the valve stem a

sharp tap with a plastic hammer to seat the valve locks.

This will aid in the proper seating of the valve locks and

reduce the chances of failure.

10-2-44