TM 5-3895-359-14&P

CYLINDER BLOCK END PLATES

A flat steel plate, one bolted to each end of the cylinder

block, provides a support for the flywheel housing at the

rear and the balance weight cover and crankshaft cover

at the front of the engine. Since the blower drive gear

assembly is supported on the rear end plate, this plate

has a different contour than the one used at the front.

Gaskets are used between the block and each end

plate.

Inspection

When an end plate is removed, it is essential that all of

the old gasket material be removed from both surfaces

of the plate and the cylinder block. Clean the end plate

as outlined under Clean Cylinder Block on Page 10-2-6.

Inspect both surfaces of each end plate for nicks, dents,

scratches or score marks and check the end plates for

warpage. Also check the tapped holes in the end plates

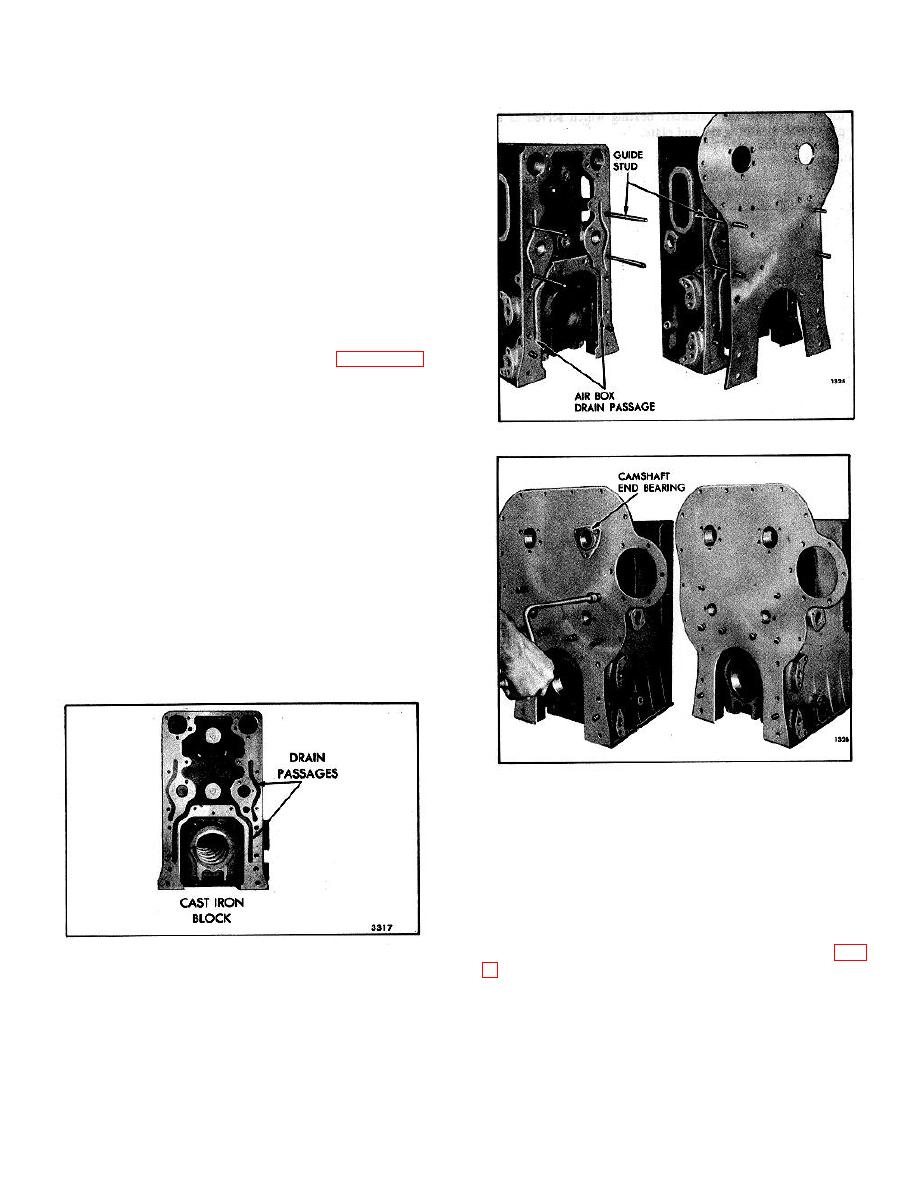

Fig. 2. Installing Front End Plate

at this time. If nicks or scratches on the sealing

surfaces of the end plates are too deep to be cleaned

up, replace the end plates.

Install End Plates

With all of the necessary plugs properly installed, the

end plate-to-cylinder block dowels in place, attach the

cylinder block front and rear end plates as outlined

below.

1. Affix a new gasket to each end of the cylinder block,

using a non-hardening gasket cement. Also apply an

even coating of gasket cement to the outer surface of

each gasket (the surface next to the end plate).

Fig. 3 - Installing Rear End Plate

2. Use guide studs J 1927-01 as shown in Fig. 2 to set

the front end plate next to the cylinder block and install

the bolts and lock washers. Do not tighten the bolts at

this time. Wipe the excess gasket cement from the

bores in the end plate and the cylinder block.

3. Insert a camshaft end bearing through the SMALL

bearing bore in the end plate and into the bore of the

block to accurately align the end plate as shown in Fig.

Fig. 1. Drain Passages in Cylinder Block

10-2-15