TM 5-3895-369-14

5-14. CRANKSHAFT REPLACEMENT/REPAIR.

This task covers:

a. Removal

INITIAL SETUP

b. Cleaning/Inspection

c. Installation

Tools

Personnel Required

Shop equipment, contact maintenance: truck

mounted

MOS62B, Construction equipment repairer (2)

Materials/Parts

Solvent, drycleaning (item 54, appendix E)

Oil, lubricating engine (item 35, appendix E)

Brush, nylon tube (item 7, appendix E)

Wear sleeves, top

Wear sleeve, bottom

Grease, general purpose (item 25, appendix E)

Gloves, protective thermal

Tags, identification (item 55, appendix E)

Equipment Condition

TM or Para

Para 5-9

Para 5-28

Para 5-29

Condition Description

Engine installed on stand

Gear housing removed.

Oil pan and suction tube

removed.

General Safety Instructions

If engine has recently been in operation, allow

engine time to cool before performing procedure,

8.

Removal.

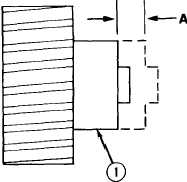

(1)

Measure and record end play at gear end of

crankshaft (1) at position A. Normal

measurement is 0.005 to 0.010 in.

(0.13 - 0.25 mm). If measurement is above

or below normal, correct with proper thrust

bearing in installation.

5-137