TM 5-3895-369-14

5-13. CYLINDER HEAD ASSEMBLY REPAIR (CONT).

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

(25)

Check valve stem tip for flatness. Resurface

tip if required.

Install each valve in cylinder block matching

marks made in disassembly.

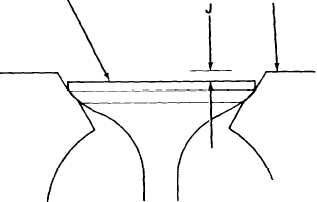

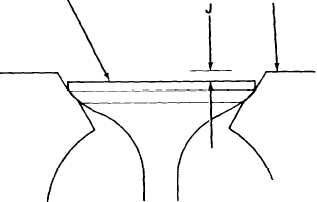

Measure and record valve depth at position

J. Normal measurement is between 0.039 to

0.060 in. (0.99 - 1.52 mm). If measurement is

below normal, grind valve seat. If

measurement is above normal, replace valve.

Check valve seats in cylinder head for burns,

scratches and other damage. If surface is

damaged, grind valve seats.

VALVE

CYLINDER

BLOCK

If valves were ground, repeat steps (12) and (13) to ensure consistent measurement of valve seats.

If valves were ground, measure valve depth again at position J. Calculate grinding depth by subtracting

present measurement by the first measurement. Grinding depth should be no greater than 0.010 in.

(0.254 mm). If greater, replace with service valve seat.

Mark cylinder head to identify ground valve seats.

Install each valve in cylinder block in accordance with matching marks made in disassembly.

Repeat step (18) to ensure proper valve depth.

Apply lapping compound to each valve and valve seat. Wipe lapping compound from valve and valve seat

with lint-free cloth.

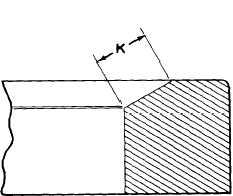

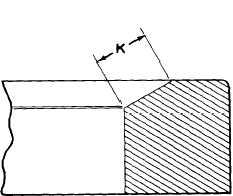

Measure valve seat width at position K.

Normal measurement is between 0.060 to

0.080 in. (1.5 - 2 mm). If measurement is

below normal, grind valve seat as required.

If measurement is above normal, replace

valve seat with service valve seat.

5-134