TM 5-3895-369-14

(10) Determine main bearing clearance as

follows:

(a)

(b)

(c)

(d)

(e)

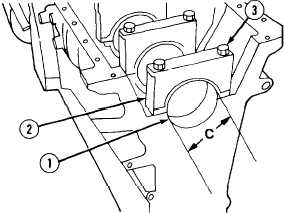

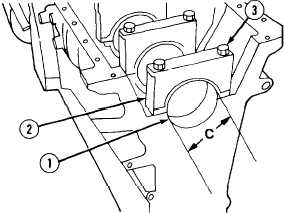

Install 14 bearings (1) in seven bearing

caps (2) and in cylinder block.

Install seven bearing caps (2) and 14

screws (3). Tighten screws 130 lb-ft

(176 N-m).

Measure and record main bore

diameters at position C. Maximum

diameter is 3.2720 in. (83.109 mm). If

measurement exceeds limit, replace

bearings. If measurement is still above

limit, replace top bearing caps.

Subtract position A (recorded in step [8]) from position C (C - A). Maximum clearance is 0.00475 in.

(0.119 mm). If measurement exceeds limit, replace crankshaft.

Remove 14 screws (3), seven bearing caps (2), and 14 bearings (1).

C.

Installation.

(1)

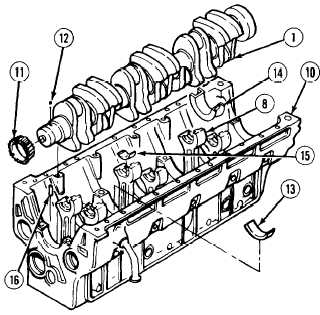

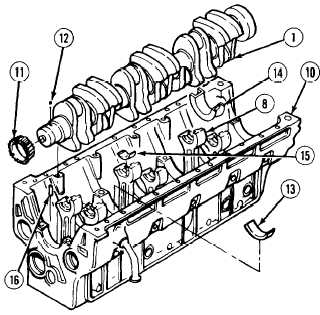

If removed, install seven piston cooling

nozzles (16) in cylinder block (10).

Do not apply grease on outer diameter of

bearing halves or damage may result to

bearing halves, related bearing caps, and

crankshaft.

(2)

Lubricate six bottom rod bearing

halves (15), thrust bearing half (14),

and six bottom bearing halves (13) on convex

side only with general purpose grease.

If top and bottom bearing halves are

exchanged, damage could result to

crankshaft journals.

(3)

Install six bottom rod bearing halves (15) on connecting rods (8).

(4)

Install thrust bearing half (14) and six bottom bearing halves (13) on cylinder block (10).

(5)

Install key (12) in crankshaft (1).

5-141