TM 5-3895-369-14

5-14. CRANKSHAFT REPLACEMENT/REPAIR (CONT).

b. Cleaning/Inspection.

(1)

Clean crankshaft oil drillings with nylon brush.

WARNING

•

Drycleaning solvent (P-D-680) is TOXIC and flammable.

Wear protective goggles and gloves; use

only in a well-ventilated area; avoid contact with skin, eyes, and clothes and do not breathe vapors.

Keep away from heat of flame.

Never smoke when using solvent; the flash point for type I

drycleaning solvent is 100°F (38°C) and for type II is 140°F (60°C). Failure to do so may result in

injury or death to personnel.

•

If personnel become dizzy while using cleaning solvent, immediately get fresh air and medical help.

If solvent contacts skin or clothes, flush with cold water. If solvent contacts eyes, immediately flush

eyes with water and get immediate medical attention.

•

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use only with effective

chip guarding and personal protective equipment (goggles/shield, gloves, etc).

(2)

Rinse crankshaft in drycleaning solvent and dry with compressed air.

(3)

Check crankshaft seals for grooving and scratches.

If damage is found, replace wear sleeves.

(4)

Check rod and main journals for deep scoring and other damage.

(5)

Check crankshaft for visible warping and wear.

(6)

Check bearing caps for dents, cracks, and other visible damage.

(7)

Check crankshaft surface for burrs. Smooth

surface as necessary.

(8)

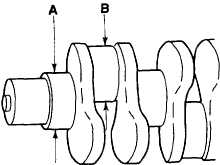

Measure and record main journal diameters

at position A. Normal measurement is

3.2662 to 3.2682 in. (82.962 - 83.013 mm).

If above or below normal measurement,

replace crankshaft.

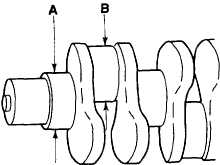

(9)

Measure rod journal diameters at posi-

tion B. Normal measurement is 2.7150 to

2.7170 in, (68.962 - 69.013 mm). If above

or below normal measurement,

replace crankshaft.

5-140