TM 5-3895-359-14&P

TRAVEL SPEED UNIT

proper integration of the voltage signals for overall

The travel speed unit, figure6, consists of a pneumatic

system accuracy.

This calibration is effected by

tire and wheel that is automatically lowered to the

removing the control knob on the front of the V.P.I.

ground when the spray bar valves are opened. The

panel with a '4'" allen wrench. On the back of the V.P.I.

wheel drives a tach-generator through an enclosed gear

panel, connect an ohmmeter to posts #3 and #5 on the

box which generates a voltage proportionate to the

gallons per square yard potentiometer and rotate the

travel speed of the Pulvi-Mixer. If the tach-generator

shaft from a high ohm setting counterclockwise until an

leads have been removed, check that the polarity is

ohmmeter reading of one (1) ohm is reached. This

correct for the direction of travel in order to get an

operation should

indicator reading.

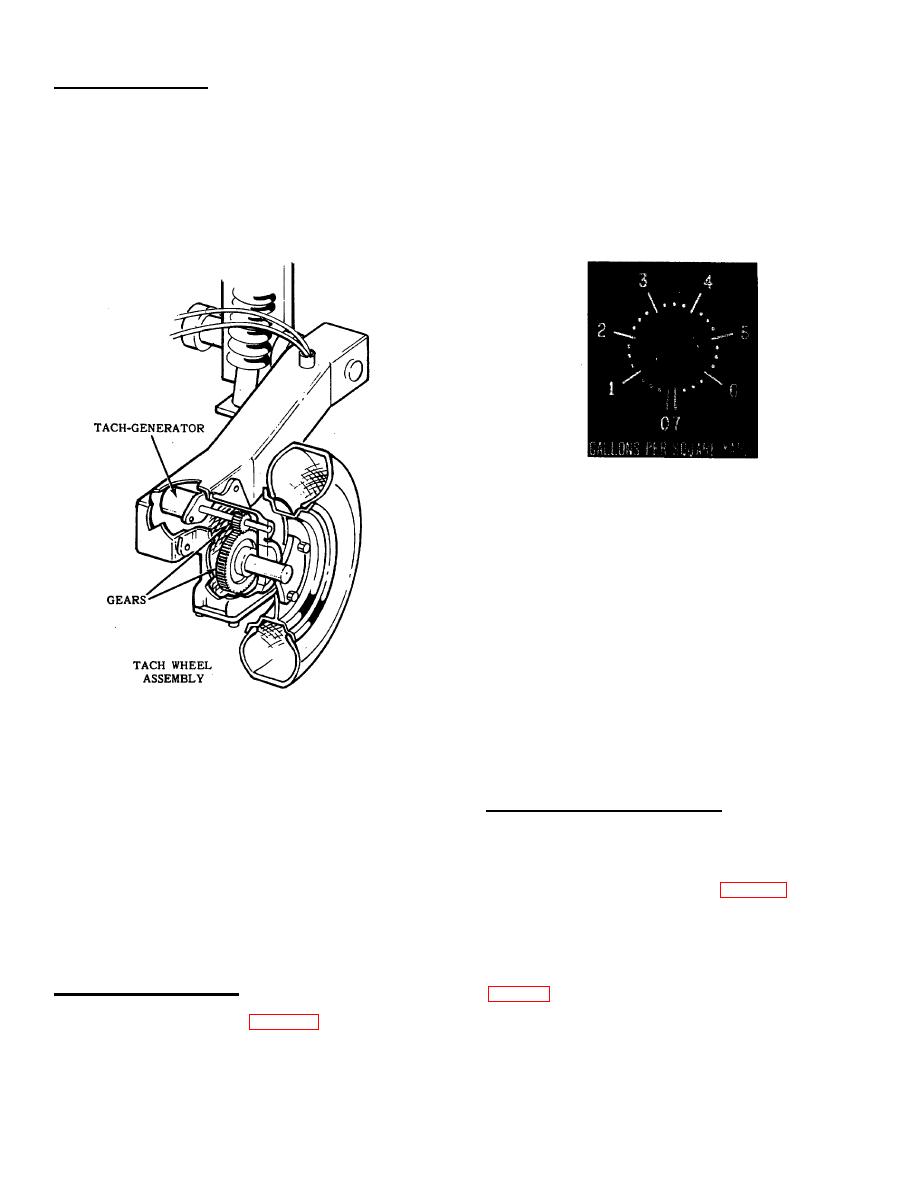

FIGURE 7

be repeated several times as there is no positive stop on

this potentiometer, only a "dead band." After the one (1)

ohm position has been determined, very carefully

replace the knob on the shaft with the pointer directed at

zero ("0") on the gallons per square yard legend plate.

Tighten the socket head set screw making sure #1, that

the one (1) ohm reading is repeatable with the pointer

directed at zero ("0") and #2, that the locking ring, when

turned clockwise holds the pointer securely at a

predetermined position.

FIGURE 6

The above operation may have to be repeated as it can

be quite delicate, however it is essential that it be done

This voltage is transmitted to the travel speed indicator

correctly.

mounted on the V.P.I. panel. The travel speed unit is

easily calibrated by measuring a suitable distance (50 ft.

PROPORTIONING SYSTEM UNIT

or 100 ft.) and timing the machine over the measured

distance maintaining a constant forward speed and

The proportioning system unit (performance meter) is

checking the rate against the indicator reading. With the

the last indicator to be adjusted in this sequence.

travel speed indicator pointer at 100 f.p.m. for example,

Before starting this adjustment procedure, check to see

the machine should traverse this distance (100 ft.) in

if the performance meter needle, figure 8, is reading

one minute. If it does not, adjust the tach wheel

zero ("0") in a rest or "no-power" position. If it is not,

potentiometer on the back of the V.P.I. panel until the

adjust the needle by slightly turning the adjusting screw

travel speed indicator reads correctly for the timed

near the bottom on the face of the meter. The

distance.

adjustment is accomplished by first selecting an

application rate from the application reference chart

APPLICATION RATE UNIT

the pointer with the locking ring.

The application rate unit, figure 7, consists of an

extremely accurate potentiometer that must be correctly

adjusted in order to signal the proportioning system the

13-4