TM 5-3895-359-14&P

CALIBRATING THE V.P.I. SYSTEM-

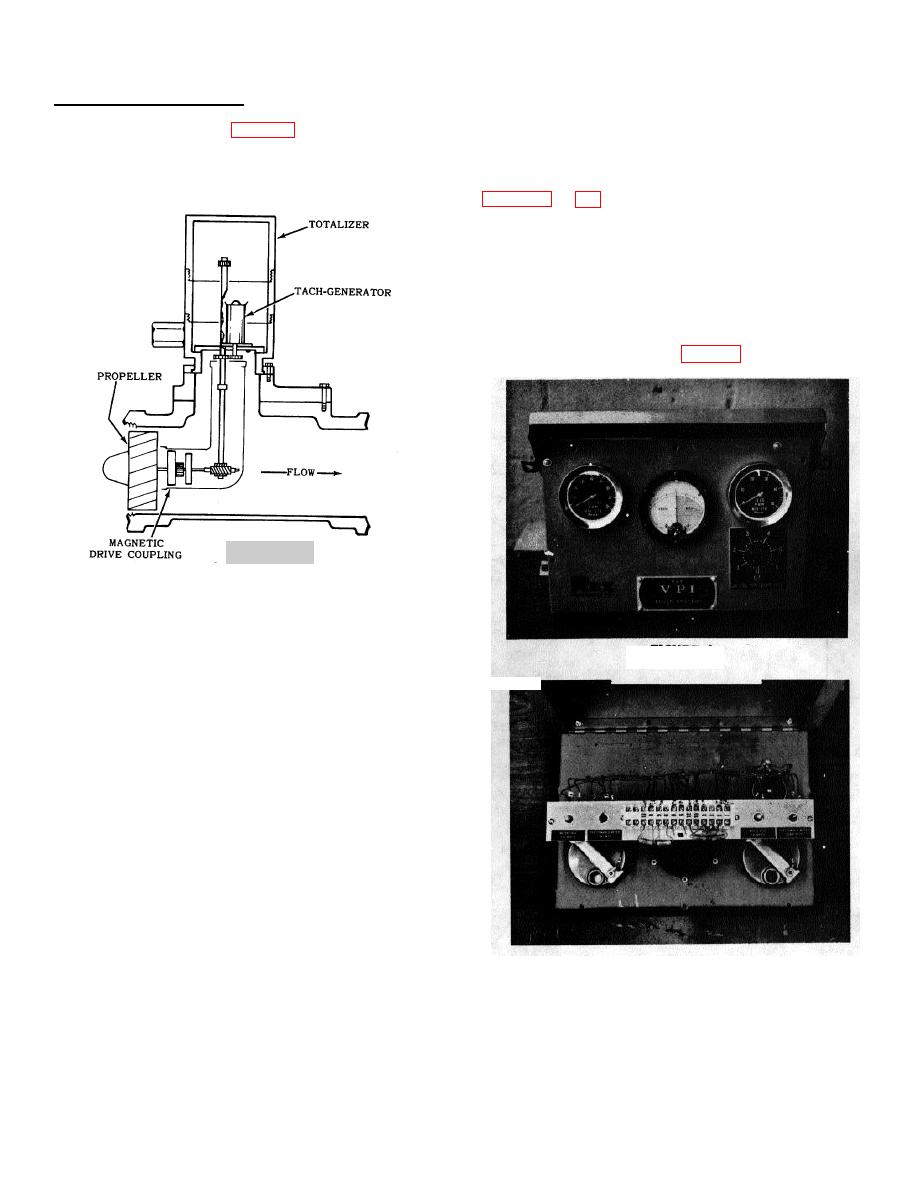

totalizer will provide a gallons per minute flow rate and

METER RECORDING UNIT

the corresponding voltage output of the meter

tachgenerator. If the air method is used for checking

The meter recording unit, figure 2, is the basic unit of

the meter flow rate, do not rotate the propeller too fast.

the V.P.I. system and the accuracy of the total system

A flow rate of 200-400 gallons per minute is a good rate

depends largely upon the accuracy of the recording

at which to check the tach-generator voltage output.

totalizer head on the meter. This is calibrated to within

2%.

a specific flow rate, the gallons per minute indicator on

the V.P.I. panel may now be calibrated. Remove the

face bolts holding the V.P.I. panel in place and fold the

panel down so that the terminal block is accessible.

Remove the leads #3 and #8 (from the meter

tachgenerator) from the terminal block. Substitute an

adjustable external D.C. voltage source to terminals #3

and #8 of the same magnitude previously determined

for the given flow rate. Refer figure 5.

FIGURE 2

In operation, the meter propeller is rotated by the liquid

flow pressure passing through the line into which the

meter propeller is inserted. The propeller drives a worm

gear train through a magnetic coupling then directly to

FIGURE 3

the recording totalizer which records the total gallons

having passed through the meter. A tach-generator

connected to the basic gear train produces a voltage

signal proportionate to the liquid flow which is relayed to

the instrument panel where it indicates the flow in

gallons per minute.

In checking out and calibrating the meter recording unit,

it is best to pump a liquid through the meter, time the

flow and check it against the totalizer, simultaneously

checking the voltage output of the meter tach-generator.

This will determine the rate of flow and corresponding

voltage output under these specific conditions. The

voltage will be used later to calibrate the "gallons per

minute" indicator. If it is impractical to actually pump a

liquid thru the system, the meter body assembly

complete with the propeller may be removed from the

system and the flow rate determined by the following

FIGURE 4

method: Place the meter body assembly on a bench so

Adjust the meter tach-generator potentiometer so that

that the propeller will rotate freely, and with the meter

the gallons per minute indicator corresponds to the

mounting flange in a horizontal plane. If the meter is

same flow rate as determined by the timed totalizer

tipped excessively, oil will be lost from the lower gear

measurement.

The meter recording unit is now

train. A Type "A" transmission fluid must be added to

calibrated.

replace the lost oil. Direct an air hose with regulating

valve so

that it will rotate the propeller at a constant low speed.

This simulation of flow, timed and checked against the

13-2