TM 5-3895-359-14&P

Carburetor; Operation, on page 14-14.

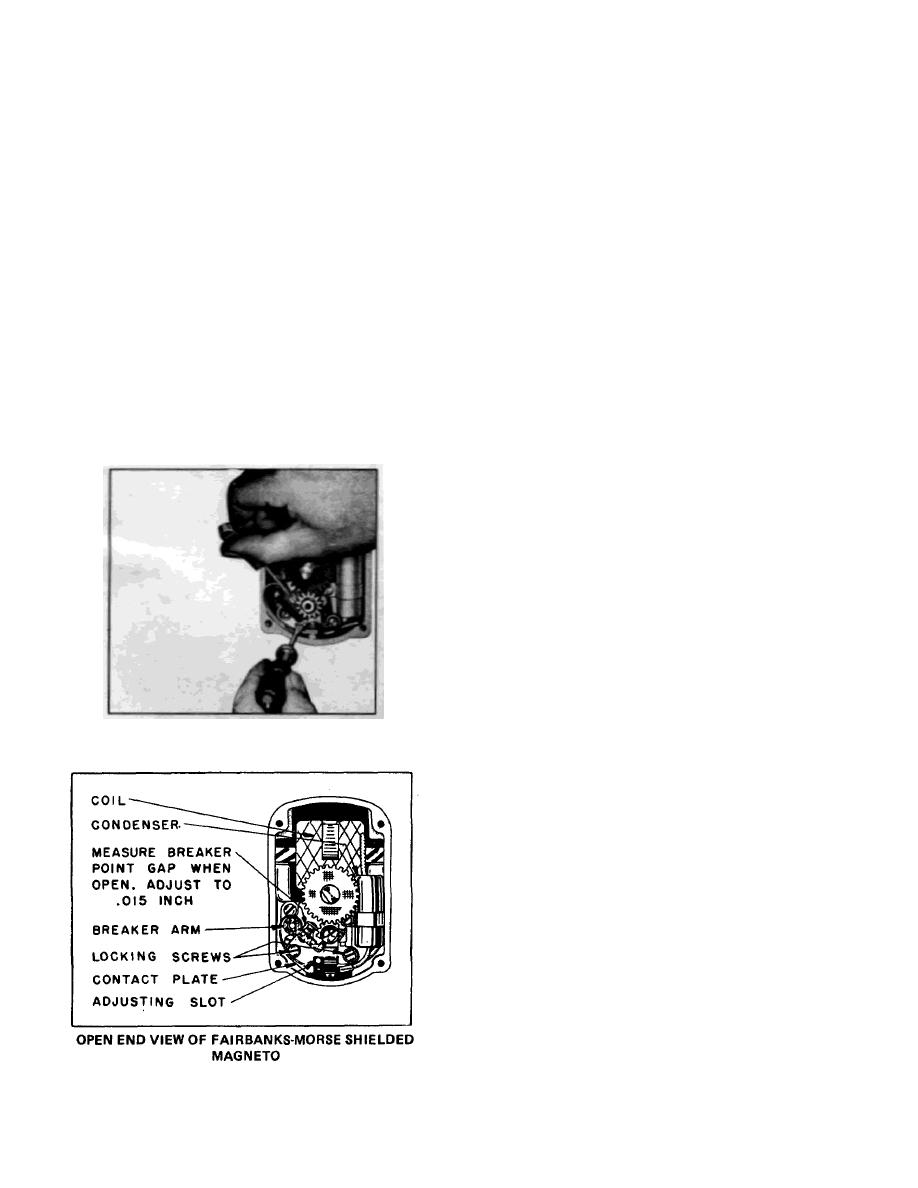

have become rough, they should be smoothed with a

breaker point file before the preceding adjustments are

MAGNETO BREAKER POINT ADJUSTMENT

made. Replace magneto end cover carefully so that it

will seal properly. Do not force cover screws too tightly

The shielded magnetos are properly adjusted before

otherwise cover may crack.

leaving factory. The breaker points on the magneto

MAGNETO IGNITION SPARK

should be .015" at full separation. If the spark becomes

If difficulty is experienced in starting the engine or if

weak after continued operation, it may be necessary to

engine misses firing, the strength of the ignition spark

readjust these points. To do this first remove the end

may be tested by disconnecting the No. 1 ignition cable

cover on the magneto. The crankshaft should then be

from the spark plug and holding the terminal about 1/8

rotated by pulsing the starter, (this also rotates the

inch away from the air shroud or any other conveniently

magneto), until the breaker points are wide open. The

located metal part of the engine. Turn the engine over

opening or gap should then be measured with a feeler

and watch for a strong spark discharge, which should

gauge as shown in Fig. 4 and if necessary reset. To

occur during the cycle at the instant the impulse

readjust points, first loosen the locking screws on the

coupling on the magneto snaps. Repeat this check with

contact plate enough so that the plate can be moved.

each of the other ignition cables. If there is a weak

Insert the end of a small screw driver into the adjusting

spark, or none at all, check breaker point opening as

slot at the bottom of the contact plate and open or

mentioned in preceding paragraph under " agneto

M

close the contacts by moving the plate until the proper

Breaker Point Adjustment" If this does not remedy the

.

opening is obtained. See Fig. 5. After tightening the

trouble, it may be necessary to install a new condenser.

locking screws, recheck breaker point gap to make sure

FIRING ORDER

it has not changed. If it is found that the breaker points

The firing order of the cylinders is 1-3-4-2, and the

magneto rotates at one-half engine speed, as is the

case with conventional "in line" engines. The intervals

between the firing of the cylinders is 180 No. 1

.

cylinder is the one nearest to the flywheel in the left

bank of cylinders, when viewed from the flywheel end of

the engine. No. 3 cylinder is the other cylinder in this

bank. No. 2 cylinder is the one nearest to the flywheel

in the right bank of cylinders and No. 4 is the other

cylinder in this bank. The cylinders are numbered from I

to 4 on the air shroud near the spark plugs. The

flywheel end of the engine is designated the front and

the power take-off end, the rear of the engine.

MAGNETO TIMING

The proper spark advance is 230. To check timing with

a neon light, the running spark advance is indicated by

a 3/8 inch slotted hole in the rim of the air intake screen,

FIGURE 4

68 left of the flywheel shroud vertical centerline,

marked VH, or if screen is removed, time to the lower

half of the 1/4 inch elongated hole on the face of

flywheel shroud 230 below the centerline of No. 1 and

No. 3 cylinders as illustrated in Fig. 11. The end of the

'X' marked vane should be whitened with chalk or paint

for this operation.

To Time Magneto to Engine: Remove air intake

screen to expose timing marks on both flywheel and

shroud. See Magneto Timing Diagram, Fig. 6.

Next, remove the spark plug from No. 1 cylinder and

slowly turn the flywheel clockwise, at the same time

holding a finger over the spark plug hole, so that the

compression stroke can be determined from the air

blowing out of the hole.

The flywheel is marked with the letters 'DC' near one of

the air circulating vanes. This vane is further

FIGURE 5

14-2