TM 5-3895-359-14&P

setting never needs adjusting and no provision for

ALTERNATOR PRECAUTIONS

adjustment is provided.

Precautions must be taken when working on or around

Remove Alternator

alternators. The diodes and transistors in the alternator

circuit are very sensitive and can be easily destroyed.

1.

Disconnect the cables at the battery supply.

Disconnect all other leads from the alternator and tag

Avoid grounding or shorting the output wires. Never run

each one to ensure correct reinstallation.

an alternator on an open circuit.

2. Loosen the mounting bolts and the adjusting strap

Grounding an alternator's output wire or terminals, which

bolt. Then remove the drive belts.

are always "hot" regardless of whether or not the engine

is running or accidental reversing of the battery polarity

3. While supporting the alternator, remove the adjusting

will destroy the diodes. Grounding the field circuit will

strap bolt and washers. Then remove the mounting

also result in the destruction of the diodes.

bolts, washers and nuts.

Remove the alternator

carefully and protect it from costly physical damage.

Accidentally reversing the battery connections must be

avoided.

4. Remove the pulley assembly if the alternator is to be

replaced.

Never disconnect the battery while an alternator is in

operation.

Disconnecting the battery will result in

Alternator Service

damage to the diodes due to the momentary high

voltage and current generated by the rapid collapse of

No periodic adjustments or maintenance are required on

the magnetic field surrounding the field windings.

the alternator assembly. However, Troubleshooting

Procedures will indicate when repairs or overhaul are

If a booster battery is to be used, the batteries must be

necessary.

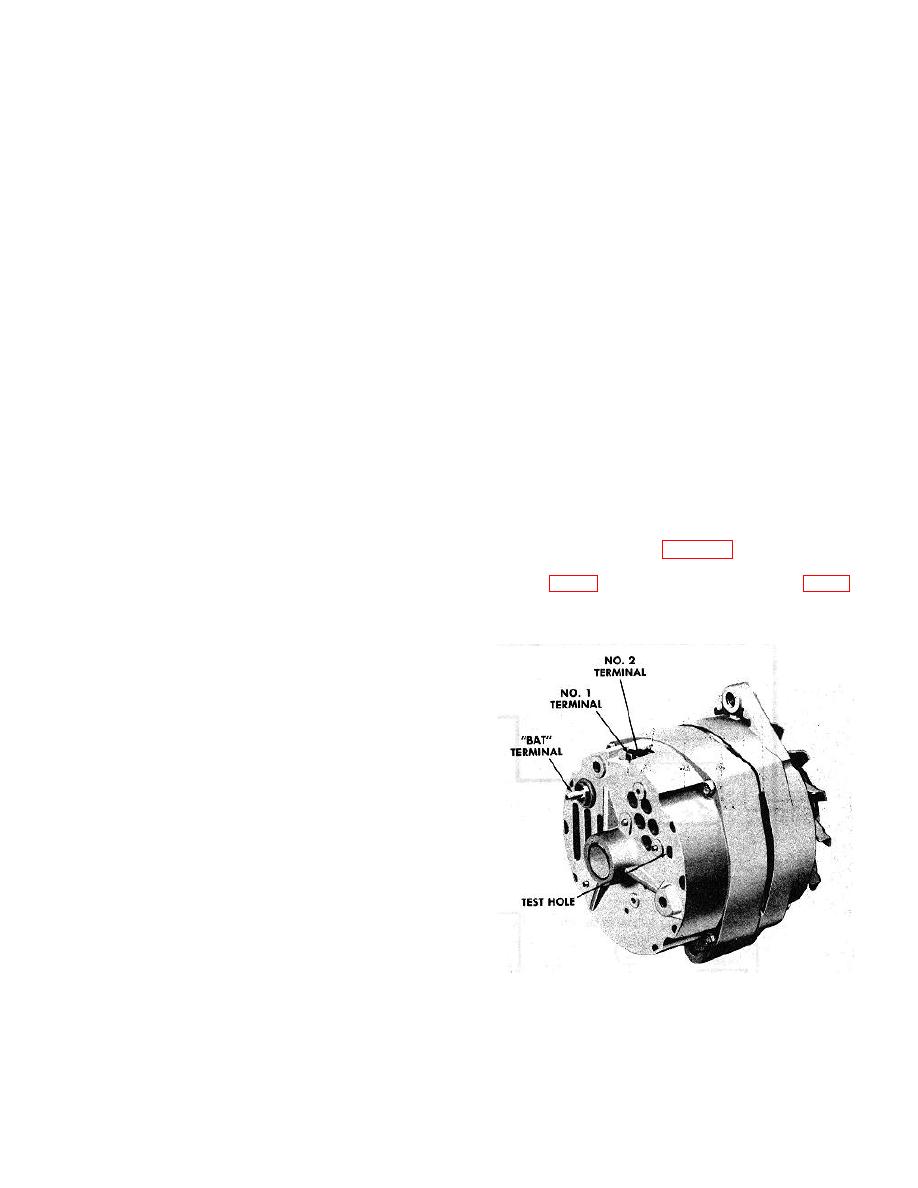

Shown in Fig.

connected correctly (negative to negative and positive

connections and the internal parts of the alternator are

to positive).

complete from the alternator to the battery through the

Never use a fast charger with the battery connected or

fuel pressure switch and ammeter when the engine is

as a booster for battery output.

running.

Never attempt to polarize the alternator.

The alternator diodes are also sensitive to heat and care

must be exercised to prevent damage to them from

soldering irons, etc.

Alternator Maintenance

1. Maintain the proper drive belt tension. Replace worn

or frayed belts.

NOTE

When installing or adjusting the

drive belt, be sure the bolt at the

pivot point is properly tightened, as

well as the bolt in the adjusting slot.

2.

Alternator bearings are permanently lubricated.

There are no external oiler fittings.

Fig. 4 - Terminal Connections.

3. The solid state regulator is mounted inside the

alternator slip ring end frame. The regulator voltage

10-8-3