TM 5-3895-359-14&P

Inspect the pressure relief valve and its seat in the

driven gear shaft must be reamed to .500" i .0005" and

pump body. If necessary, install new parts.

bushings used with the .623" diameter shaft must be

reamed to .625"* .0005".

Assemble Oil Pump

Inspect the bushings in the pump body and cover. If the

bushing are worn excessively, replace the pump body

Refer to Fig. 3, and assemble the oil pump as follows:

and cover assemblies unless suitable boring equipment

is available for finishing the new bushings. When

1. If the drive gear (23) was removed from the drive

installing new bushings, replace all of the bushings. The

shaft (13), insert the Woodruff key (14) in the keyway

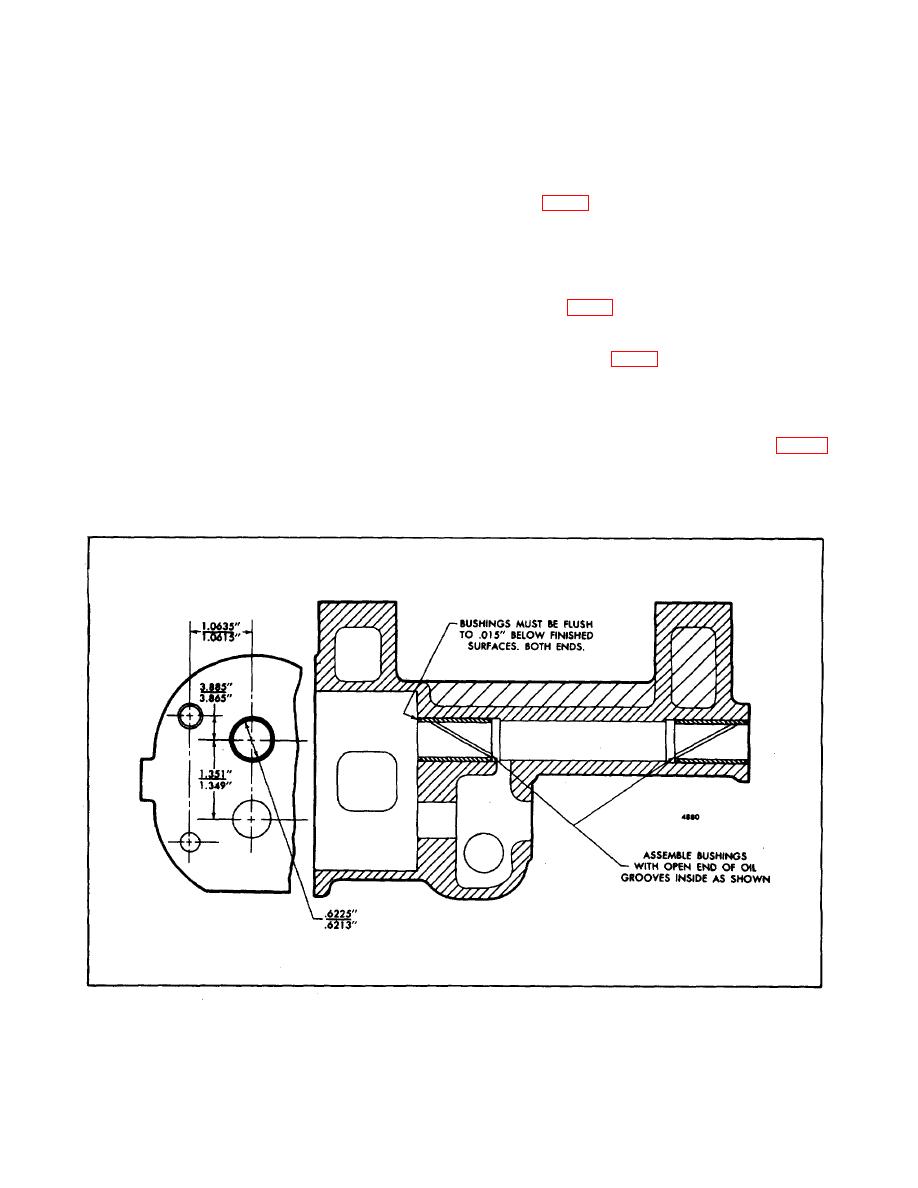

bushings must be located and positioned as shown in

and apply a light coat of engine oil on the shaft. Start

Fig. 6. Also, the gear bore and the bushing bore in both

the shaft squarely into the bore of the gear and, as

the pump body and cover must be concentric within

shown in Fig. 5, press the shaft into the gear.

.001". The shaft-pump body-bushing clearance with

new parts is .0008" to .0025". The shaft-to-pump cover

The gear must be 6-15/16" from the keyway end of

bushing clearance with new parts is .0010" to .0027".

the drive shaft (Fig. 7).

In an efficient oil pump, the gears should have a free-

2. Press the dowel (88) into the pump body, if removed.

running fit (with no perceptible looseness) in the pump

housing. If the gear teeth are scored or worn, install

3. Place the idler gear support (82) in position against

new gears. The use of excessively worn gears will

the forward end of the pump body (Fig. 3) and

result in low engine oil pressure which in turn, may lead

secure the support to the body with bolt (86).

to serious damage throughout the engine.

Fig. 6 - Diameter and Location of Bushing in Oil Pump.

10-5-8