TM 5-3895-359-14&P

3. Grind the top surface of the insert with the 15 wheel

to narrow the width of the seat to the dimensions shown

in Fig. 14. The 31face of the insert may be adjusted

relative to the center of the valve face with the 15 and

60 grinding wheels.

NOTE:

Do not permit the grinding wheel to

contact the cylinder head when

grinding the insert. When an insert

has been ground to the extent that

the grinding wheel will contact the

cylinder head, install a new insert.

The maximum amount the exhaust valve should

protrude beyond the cylinder head (when the valve is

closed) and still maintain the proper piston-to-valve

clearance is shown in Fig. 14. Grinding will reduce the

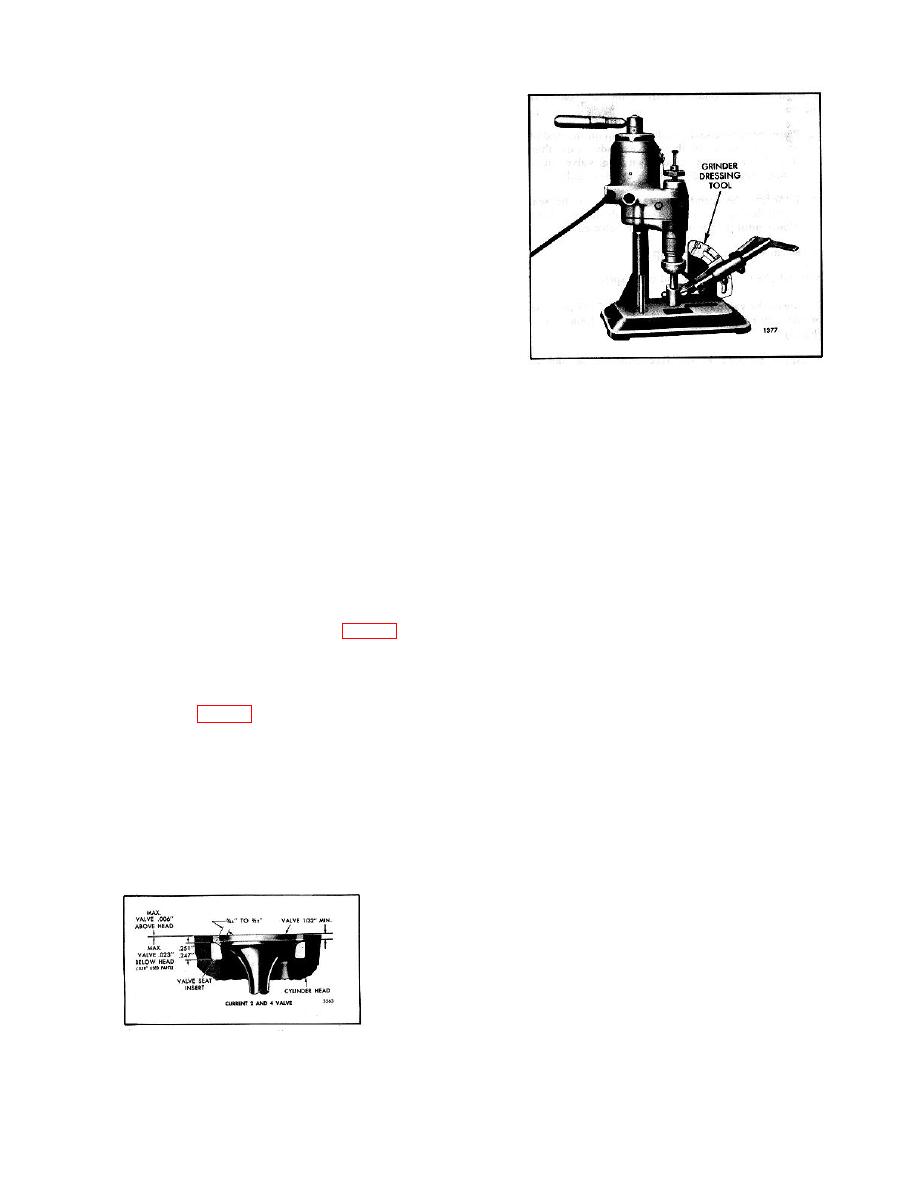

Fig. 15. Grinding Wheel Dressing Tool or Set J

thickness of the valve seat insert and cause the valve to

8165-1

recede into the cylinder head. If, after several grinding

2. Lower the stem of the valve in the valve guide and

operations, the valve recedes beyond the specified

"bounce" the valve on the seat. Do not rotate the valve.

limits, replace the valve seat insert.

This procedure will show the area of contact on the

NOTE:

valve face. The most desirable area of contact is at the

The engine must incorporate valve

center of the valve face.

seat inserts that are no more than

NOTE:

.251" thick to ensure adequate

The use of valve lapping compounds

clearance between the pistons and

is not recommended.

the exhaust valves.

After the valve seat inserts have been ground and

When occasion requires, the grinding wheel may be

checked, clean the cylinder head before installing the

dressed to maintain the desired seat angle with the

valves.

dressing tool provided with the grinder set (Fig. 15).

Install Exhaust Valves and Springs

4. After grinding has been completed, clean the valve

seat insert thoroughly with fuel oil and dry it with

Install the exhaust valves as follows:

compressed air. Set the dial indicator J 8165-2 in

position as shown in Fig. 13 and rotate it to determine

1. Clean the valve guides.

the concentricity of each valve seat insert relative to the

valve guide. If the runout exceeds .002 ", check for a

2. Lubricate the valve stems with sulphurized oil (E.P.

bent valve guide before regrinding the insert.

type) and slide the valves all the way into the guides.

After the valve seat insert has been ground, determine

IMPORTANT:

the position of the contact area between the valve and

If reconditioned valves are used,

the valve seat insert as follows:

install them in the same relative

location from which they were

1. Apply a light coat of Prussian blue, or a similar paste,

removed.

to the valve seat insert.

3. Hold the valves in place temporarily with a strip of

masking tape. Then turn the cylinder head right side up

on the work bench. Place a board under the head to

support the valves and to provide clearance between

the cam followers and the bench.

4. Install the valve spring seats.

Fig. 14 - Relationship Between New Exhaust Valve,

Insert and Cylinder Head

10-2-43