TM 5-3895-359-14&P

NOTE: Tightening the cylinder head

bolts will not correct a leaking

compression gasket or seal. The head

must be removed and the damaged

gasket or seal replaced.

9. Tighten the two flywheel housing attaching bolts

directly below the rear lifter bracket. Install a new

gasket and secure the rear engine lifter bracket to the

cylinder head and the flywheel housing. Tighten the

bolts to 55-60 lb-ft (75-81 Nm) torque. (Fig. 14).

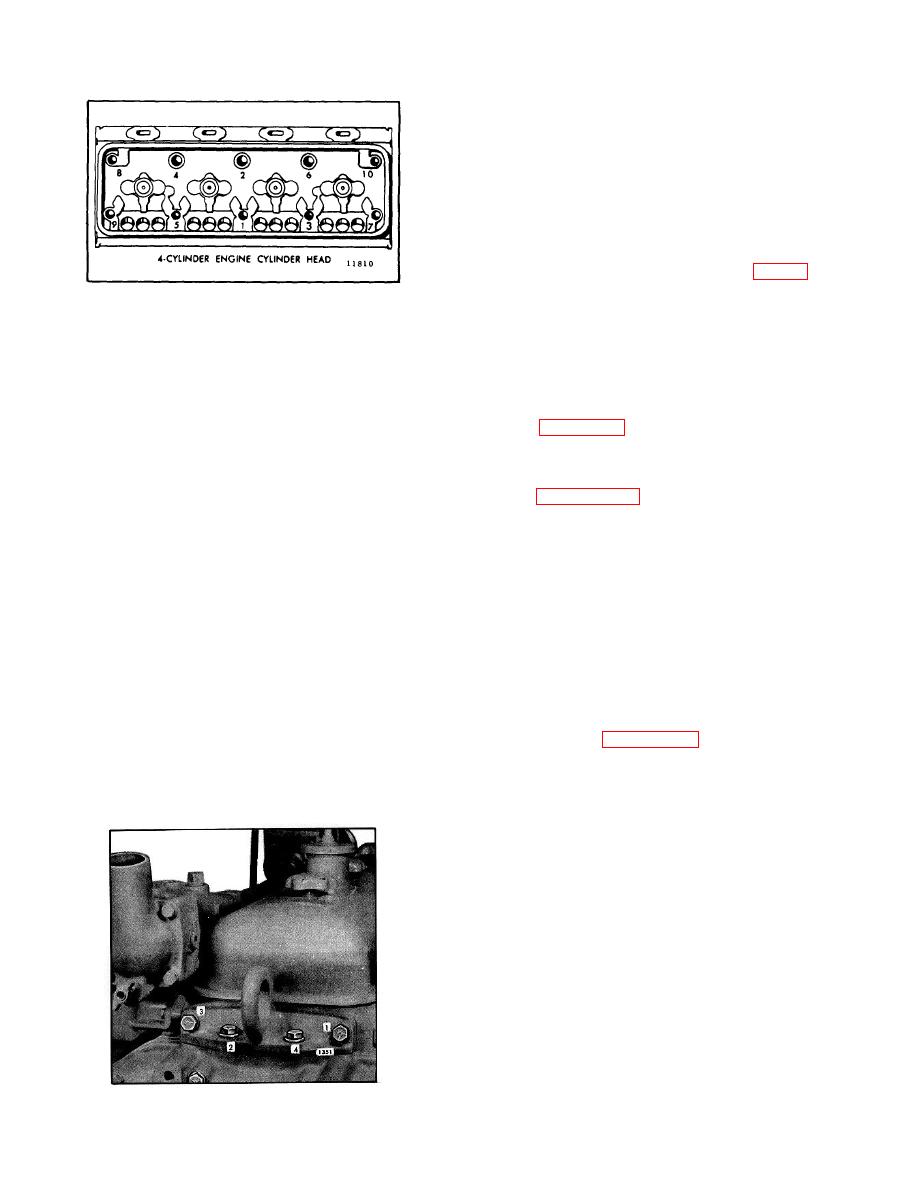

Fig. 13 Cylinder Head Bolt Tightening Sequence

10. Affix a new gasket to the front lifter bracket (or vent

casting) and attach the bracket to the cylinder head and

7. After the head is in place, remove the guide studs

the balance weight cover. Tighten the bolts in the same

and chain hoist and install the remaining bolts, running

sequence and to the same torque as on the rear lifter

all bolts down snug tight with a speed handle (15-20 lb-ft

bracket bolts.

or 20-27 Nm torque). However, before tightening the

bolts, loosen the lifter bracket-to-cylinder head attaching

11. If the fuel injectors were not previously installed,

bolts, otherwise the head may be prevented from

refer to Page 10-3-8 or 10-3-23 and install them at this

seating properly on the cylinder block.

A similar

time.

condition could exist if the exhaust manifold is attached

to cylinder head. Clearance must be assured between

12. Tighten the rocker arm bracket bolts to the specified

the exhaust manifold and the bosses on the cylinder

torque (Page 10-2-140).

block.

13. Align the fuel pipes and connect them to the

8. Tighten the bolts to 175-185 lb-ft (238-251 Nm)

injectors and the fuel connectors. Use socket J 8932-01

torque in 50 lb-ft (68 Nm) increments with a torque

to tighten the connections to 12-15 lb-ft (16-20 Nm)

wrench, in the sequence shown in Fig. 13. Repeat the

torque.

tightening sequence at least once, because the first

CAUTION: Do not bend the fuel pipes

bolts tightened in the sequence tend to lose significant

and do not exceed the specified torque.

clamp load during tightening of the remaining bolts.

Excessive tightening will twist or

Apply a steady pressure for two or three seconds at the

fracture the flared ends of the fuel pipes

prescribed torque to allow the bolts to turn while the

and result in leaks.

Lubricating oil

gaskets yield to their final designed thickness. Begin on

diluted by fuel oil can cause serious

the cam follower side of the head to take up tension in

damage to the engine bearings (refer to

the push rod springs. Tighten the bolts to the high side

Pressurize Fuel System Check for

of the torque specification, but do not exceed the limit or

Leaks on Page 10-3-56).

the bolts may stretch beyond their elastic limits.

Attempting to tighten the bolts in one step may result in

14. Set the injector control tube assembly in place on

trouble and consequent loss of time in diagnosis and

the cylinder head and install the attaching bolts linger

correction of difficulties, such as compression leaks,

tight. When positioning the control tube. be sure the

when the engine is put into operation.

ball end of each injector rack control lever engages the

slot in the corresponding injector control rack. With one

end of the control tube return spring hooked around an

injector rack control lever and the other end hooked

around a control tube bracket, tighten the bracket bolts

to 10-12 Ib-ft (14-16 Nm) torque.

15. After tightening the bolts, revolve the injector

control tube to be sure the return spring pulls the injector

racks out (no-fuel position) after they have been moved

all the way in (full-fuel position). Since the injector

control tube is mounted in self-aligning bearings, tapping

the tube lightly will remove any bind that may exist. The

injector racks must return to

Fig. 14. Lifter Bracket Bolt Tightening Sequence

10-2-27