TM 5-3895-359-14&P

Measure the cam follower bores in the cylinder head

with a telescope gage and micrometer and record the

readings. Measure the diameter of the cam followers

with a micrometer. Record the readings and compare

the readings of the followers and bores to determine the

cam follower-to-bore clearances (refer to Page 10-2-137

for specifications).

If the push rod breaks or is damaged, the rocker arm

should be suspect. Any wear or excessive movement in

the rocker arm or clevis can put a side load on the push

rod, resulting in fracture or damage. Before replacing

the push rod, inspect the rocker arm for signs of wear or

cracking. If wear or excessive movement of the rocker

arm or clevis is noted, replace the rocker arm.

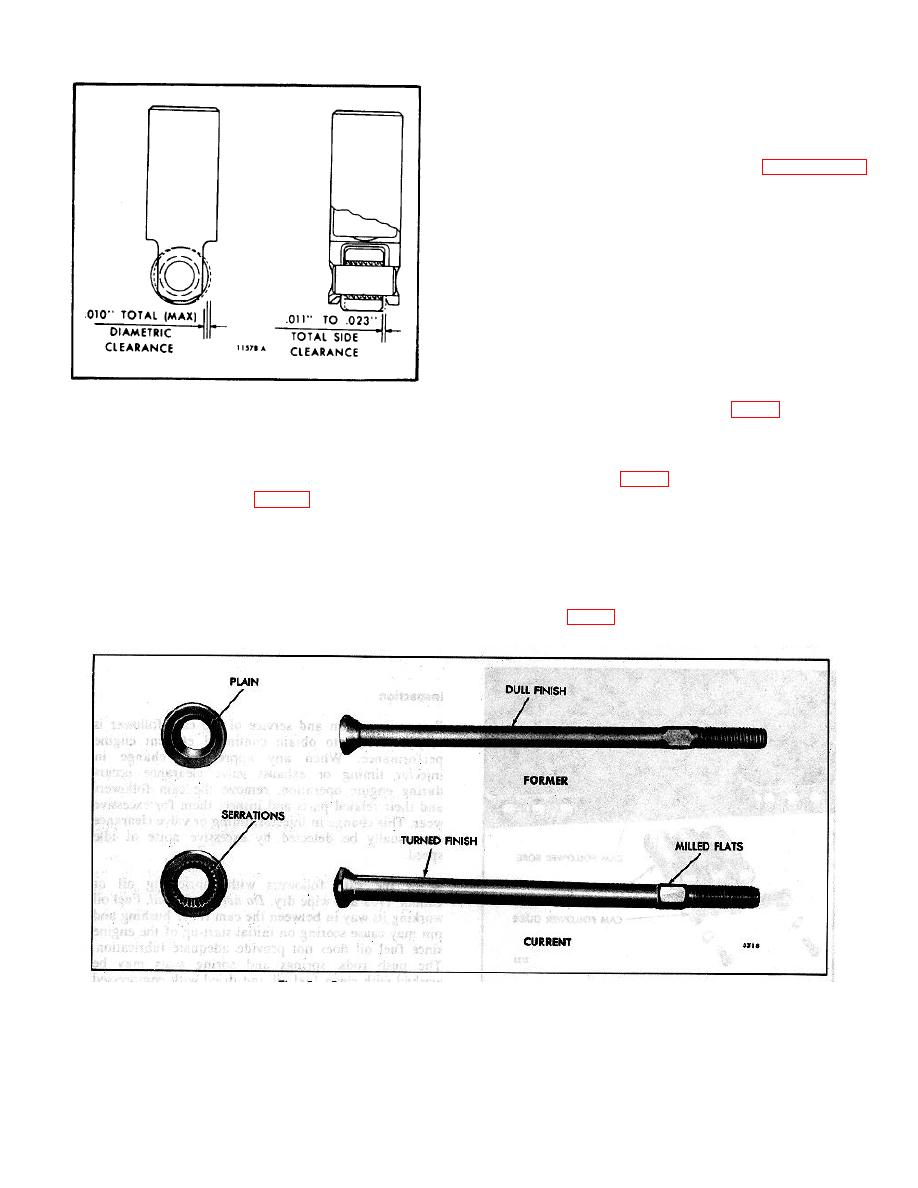

Inspect the push rods and spring seats for wear. The

current push rods have milled wrench flats and a bright

"turned" finish and the lower spring seats are serrated

Fig. 5. Cam Roller Clearances

along the push rod contact surfaces (Fig. 6).

Examine the cam follower rollers for scoring, pitting or

NOTE: When replacing a push rod or

flat spots. The rollers must turn freely on their pins.

lower spring seat, do not use a plain

Measure the total diametric clearance and side

spring seat (Fig. 6) with a current type

clearance. Install a new roller and pin if the clearances

push rod. Any other combination of

exceed those specified in Fig. 5. Cam followers

spring seat and push rod may be used.

stamped with the letter "S" on the pin, roller and follower

body are equipped with an oversize pin and roller. The

Examine the cam follower springs for wear or damage

same clearances apply to either a standard or oversize

and check the spring load. Replace a spring when a

cam follower assembly.

load of less than 172 lbs. will compress it to a length of

2.125". Use spring tester J 22738-02 to check the

Examine the camshaft lobes for scoring, pitting or flat

spring load (Fig. 7).

spots. Replace the camshaft if necessary.

Fig. 6. Comparison of Push Rods and Lower Spring Seats

10-2-32