TM 5-3895-359-14&P

location to another. If this is done it

Non-Fluorescent Penetrant Method: The test area

could result in permanent damage to

being inspected is sprayed with "Spotcheck" or Dye

the tool.

Check. Allow one to thirty minutes to dry. Remove the

excess surface penetrant with clean cloths premoisened

b. Install scrap or dummy injectors to ensure

with cleaner / remover. DO NOT flush surface with

proper seating of the injector tubes. Dummy

cleaner / remover because this will impair sensitivity.

injectors may be made from old injector nuts

Repeat this procedure with additional wipings until

and bodies -the injector spray tips are not

residual surface penetrant has been removed. Shake

necessary. Tighten the injector clamp bolts to

developer thoroughly until agaitator rattles. Invert spray

20-25 Ib-ft (27-34 Nm) torque.

can and spray short bursts to clear valve. Then spray

c. Apply 40 psi (276 kPa) air pressure to the water

this developer film evenly over the test area being

jacket. Then immerse the cylinder head in a

inspected. Allow developer film to dry completely

tank of water, previously heated to 180-200

F

before inspecting. Recommended developing time is 5

(8293 C), for about twenty minutes to thoroughly

to 15 minutes.

heat the head. Observe the water in the tank

for bubbles which indicate a leak or crack.

The above four methods provide basic instructions.

Check for leaks at the top and bottom of the

Specific details should be obtained from the supplier of

injector tubes, oil gallery, exhaust ports, fuel

the equipment or material.

manifolds and the top and bottom of the cylinder

head.

Pressure Check Method: Pressure check the cylinder

d. Relieve the air pressure and remove the

head as follows:

cylinder head from the water tank.

Then

remove the plates, gaskets and injectors and

a. To seal off the water holes in the cylinder head,

dry the head with compressed air.

assemble tool set J 28454 as follows (Fig. 7):

2. Check the bottom (fire deck) of the cylinder head for

flatness:

1. Install the rubber stoppers on the bridges.

a. Large stoppers are installed on the

long center bridge feet opposite the

a. Use a heavy, accurate straight-edge and feeler

notch and on the long end bridge

gages, tool J 3172, to check for transverse

feet closest together.

warpage at each end and between all cylinders.

Also check for longitudinal warpage in six places

b. Small

stoppers

are

installed

as shown in Fig. 8. Refer to Table 1 for

opposite the large stoppers on

maximum allowable warpage.

center bridge and end bridge feet

and on all short bridges.

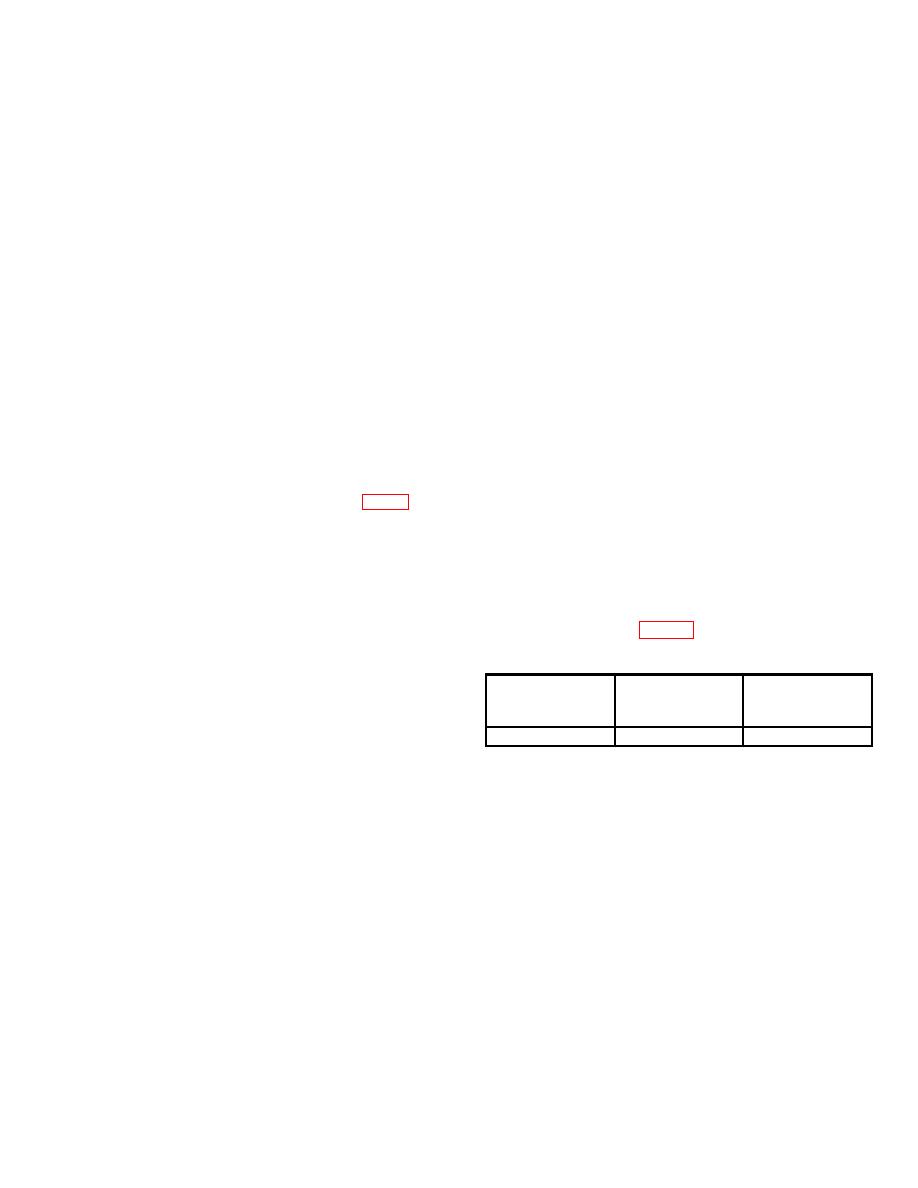

Maximum

Maximum

2. Install the necessary parts, loosely, on the

Engine

Longitudinal

Transverse

cylinder head.

Warpage

Warpage

3. Tighten the hold down bolts until the

4-71

.008"

.004"

stoppers start to distort. A 5 Ib-ft (7 Nm)

TABLE 1

torque is usually sufficient.

NOTE: Do not overtighten the hold

b. Use the measurements obtained and the limits

down bolts. The rubber stopper could

given in Table I as a guide to determine the

distort enough to seal both the inner and

advisability of reinstalling the head on the

outer diameter of the water nozzles. If

engine or of refacing it. The number of times a

the outer diameter is sealed, a leak

cylinder head may be refaced will depend upon

from the outer diameter would not be

the amount of stock previously removed.

detected.

c. If the head is to be refaced, remove the injector

4. Install the air supply plate.

tubes prior to machining. Do not remove more

metal from the fire deck of any cylinder head

below the minimum distance of 3.536" (Fig. 9).

CAUTION:

Do not hook onto the

pressure checking tool, or any part of it,

to move the cylinder head from one

10-2-23