TM 5-3895-359-14&P

adjacent block surfaces and wipe off any

that gets on the fire deck or liner bores.

3. Allow the adhesive to dry to a high-tack

consistency (stickiness) before installing

the seal. This permits the evaporation of

the liquid propellant used with the

adhesive. Do not apply adhesive directly

to the seal. The adhesive will coat the

inner diameter of the seal and the spray

propellant may cause the seal to swell

temporarily.

c. Install a new oil seal in the groove at the

perimeter of the cylinder block. The seal must

lay flat in the groove and must not be twisted or

stretched when installed. Installing the seal strip

in the groove with the colored stripe facing away

from the cylinder bores can improve its sealing

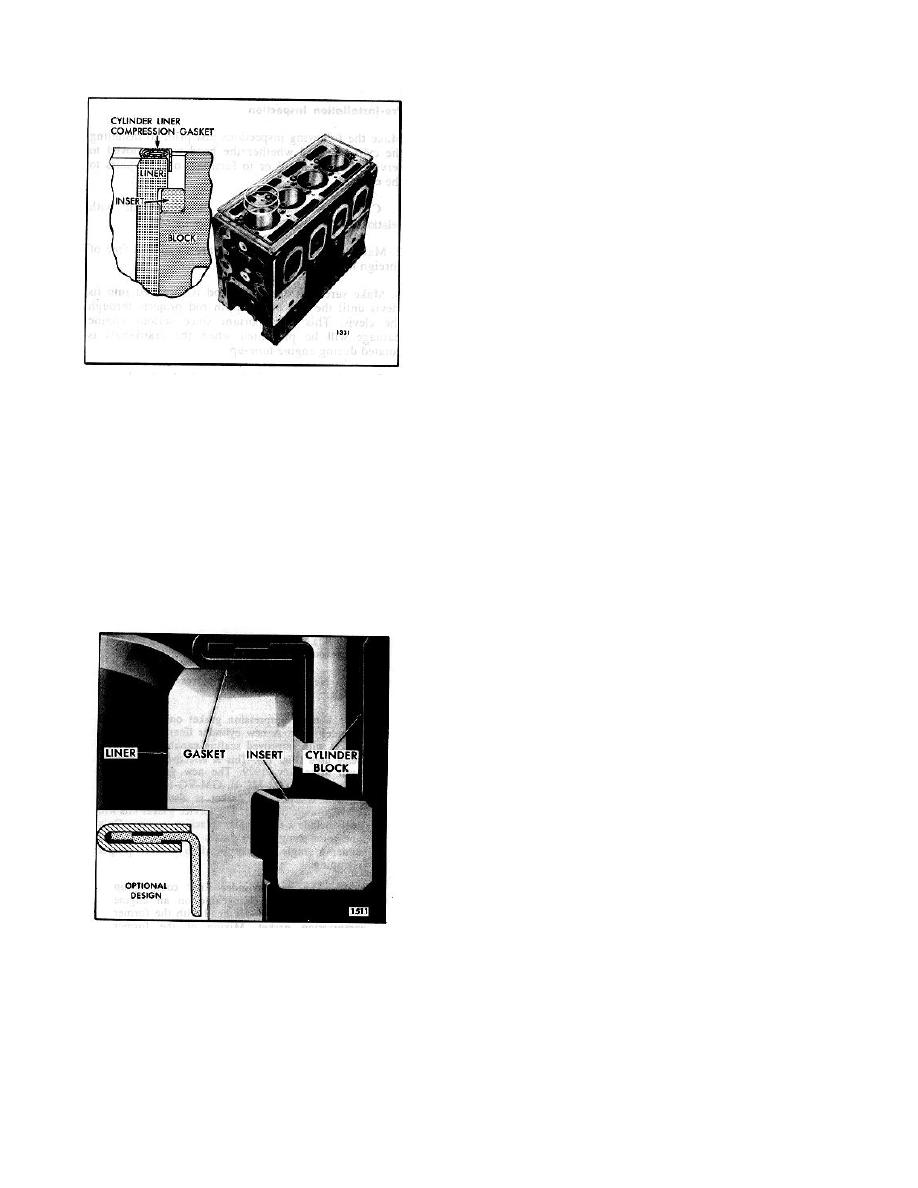

Fig. 11 Cylinder Head Seals and Gaskets

capabilities.

b. Place new seal rings in the counterbores of the

NOTE:

3M Company Super-Tack

water and oil holes in the cylinder block.

Gasket adhesive #8082 or equivalent

Silicone composition water hole seals can be

may also be used to hold the peripheral

damaged if they move out of position in the

head-to-block oil seals in place during

cylinder block counterbore during engine

engine rebuild.

rebuild. In turn, damaged seals can allow

engine coolant to contaminate lube oil and

2. To install the cylinder head on the engine without

cause serious engine damage. To prevent this,

disturbing the gaskets and seals, install guide studs J

a spray adhesive may be used to hold seals in

9665 in two corner bolt holes in the cylinder block.

place if the following precautions are taken:

1. Attach a mask or template to the cylinder

3. Insert the hooks of a chain, attached to a hoist, in the

block tire deck to minimize overspray.

vent holes of the cylinder head, or the lifter brackets,

and lift the head into position above the cylinder block.

4. Make a final visual check of the compression gaskets

and seals to ensure that they are in place before the

cylinder head is lowered. This is a very important

check. Gaskets and seals which are not seated properly

will cause leaks and "blow-by" and result in poor engine

performance and damage to the engine.

5. Wipe the bottom of the cylinder head clean. Then

lower the head until it is about 1/2" from the surface of

the cylinder block.

6. Apply a small amount of International Compound No.

2, or equivalent, to the threads and underside of the

head of all cylinder head attaching bolts. Then install

bolts at the corners of the head and thread them finger

tight into the cylinder block. Continue to tighten these

Fig. 12. Compression Gasket Mounting in Cylinder

bolts (finger tight) as the head is lowered into position on

Block

the cylinder block.

2. Using a high-tack, spray tube adhesive

suitable for synthetic rubber seals (3M

NOTE:

Cylinder head bolts are

Company Super-Tack Gasket Adhesive

especially designed for this purpose and

#8082, or equivalent), spray a light,

must not be replaced by ordinary bolts.

uniform coating of adhesive into the seal

counterbores. Keep the adhesive off of

10-2-26