TM 5-3895-359-14&P

REPLACING CENTER SECTION ASSEMBLIES IN

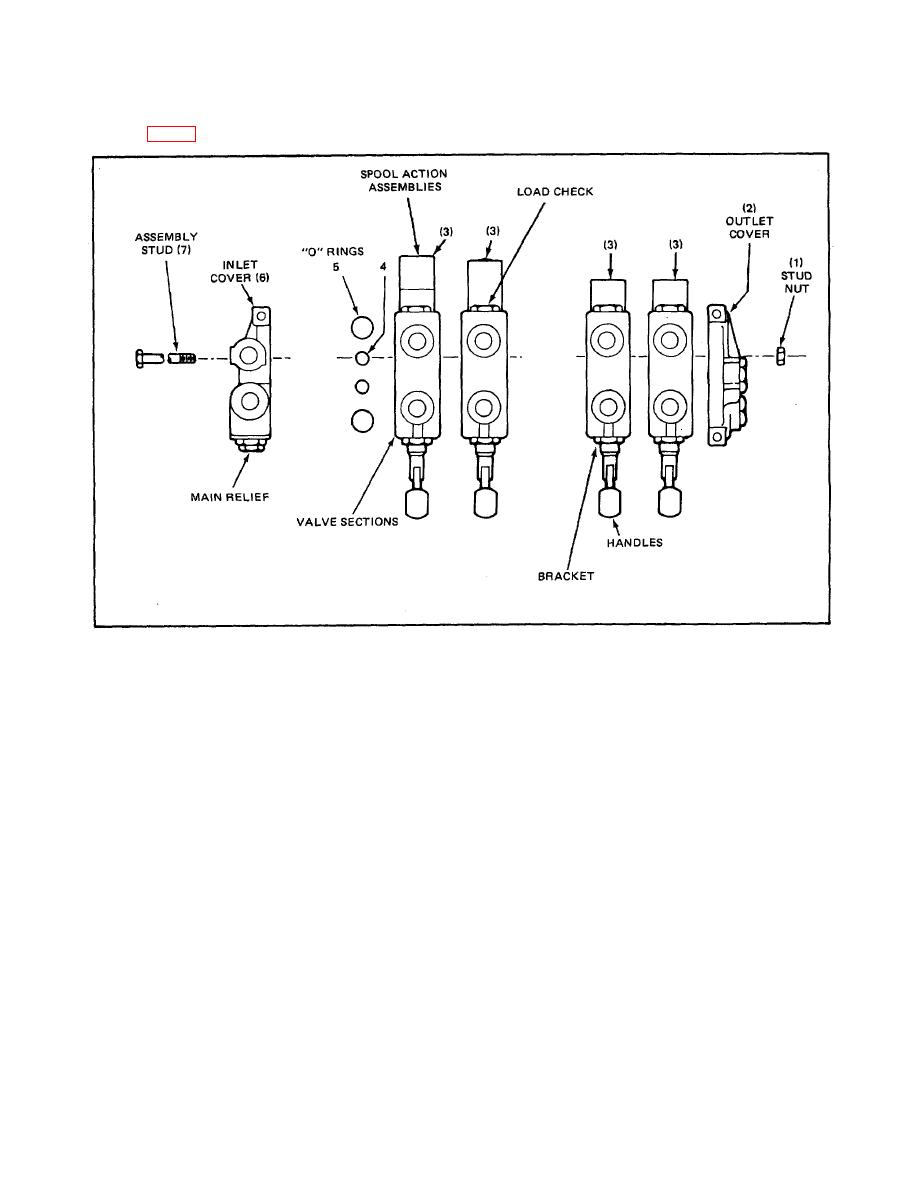

THE VALVE (Fig. 4)

FIGURE 4 Model V20 Directional Control Valve, Typical Main Assembly

For the purpose of these instructions, we shall consider

5. Next, valve sections may be disassembled by

the section containing the main relief valve the left side

sliding the sections (2), (3), (6) along the

of the valve.

assembly studs.

1. If the valve is to be reassembled in the same

6. Thoroughly clean the "0" ring counterbores and

order, it is suggested that before disassembling,

the ground surface of each section. Place new

each section be marked numerically so that they

"O" ring seals (4), (5) in proper counterbores.

may be returned to the same sequence when

For better sealing, it is suggested that all "O"

reassembled.

rings used in the counterbores be replaced with

2. If valve has been removed from equipment, it is

new parts.

advisable to mount valve vertically in a vise to

7. Replace the sections on assembly studs with the

facilitate disassembly and assembly.

"O" ring counterbores facing right end of valve.

3. On the right end of the valve there may be a

Use care in replacing sections so the section

power beyond sleeve, conversion plug or closed

"O" rings are not dislodged from the

center plug installed. These must be removed

counterbores.

before the valve can be disassembled.

8. When all sections are assembled on assembly

4. Remove the three assembly stud nuts (1) from

studs, tighten the assembly stud nuts or bolts

right end section.

evenly to 32 ft. lbs. torque, NO MORE, NO

LESS, otherwise spools may bind or stick.

8-4