TM 5-3895-359-14&P

d. Inspect shafts at bearing points and seal areas

for rough surfaces and excessive wear.

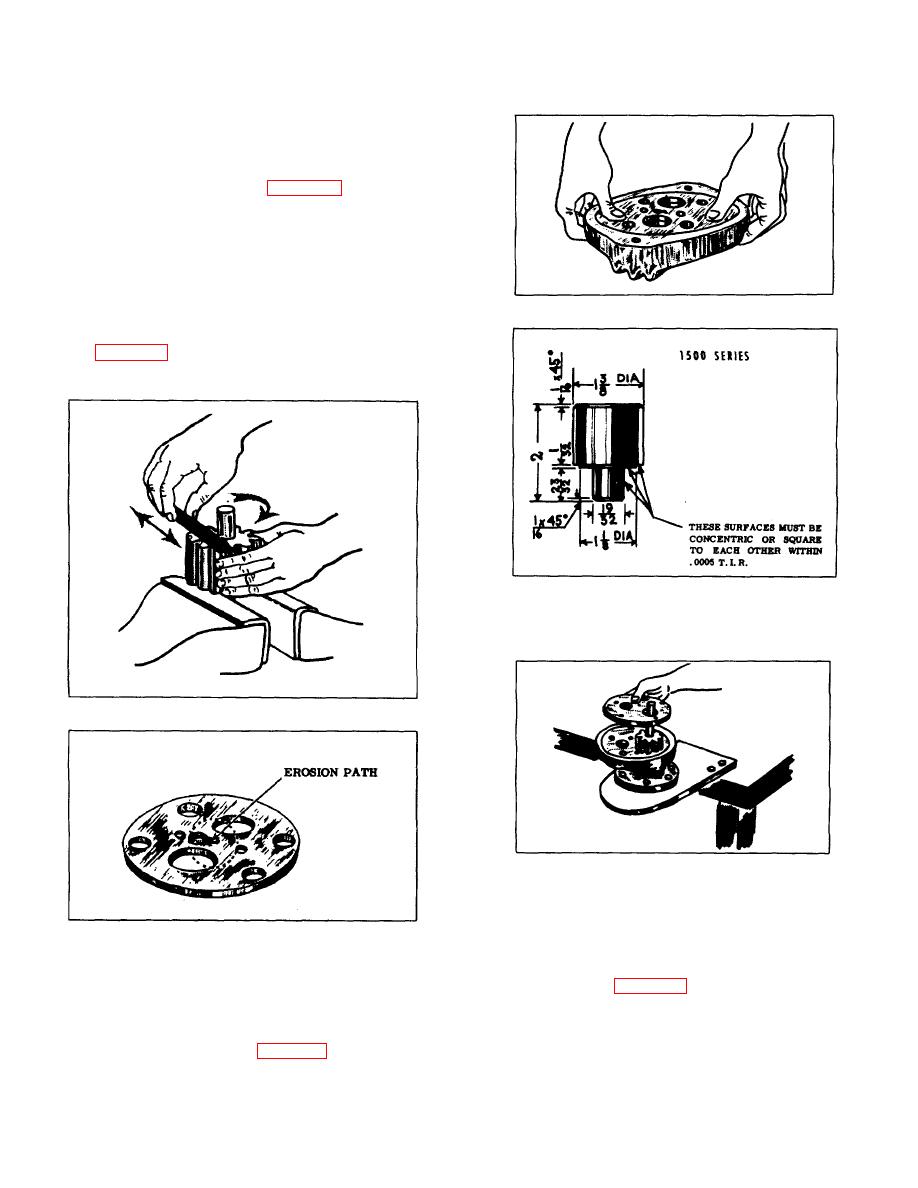

e. Inspect edges of gear teeth and gear face for

scoring. Stone the face of gears and edge of

teeth before reassembly. (Figure 12).

f. Inspect roller bearings as outlined for wear,

etc.

g. Gaskets should be replaced.

Seal rings

should be replaced.

h. Replace worn or scored wear plates. Inspect

for erosion near the relief hole on bronzed side of

FIGURE 14 Wear Plate Seating Check

gear. Slight gear pattern wear is permissible.

Plates showing erosion path should be replaced.

i.

Check for proper seating of wear plates in

FIGURE 15 Tool Dimensions for Pressing Bearings

k. Install dowel pins in adapter and cover.

l. Support adapter in vise or fixture. Insert

FIGURE 12 Use of India Stone on Gears

FIGURE 16 Assembly of Drive Shaft and Wear Plate

Inner

drive shaft in driven gear shaft bearing with long

(drive end) up.

FIGURE 13 Erosion

m.

Place inner wear plate over drive shaft,

cover and in adapter. A rocking motion indicates

making sure the bronzed surface with relief hole is

either a burr or nick on adapter or cover.

facing gear. (Figure 16).

j. Lubricate roller bearings with light grease.

n.

Place roller bearing on the drive shaft.

Coat I.D. of bearing bore with white lead. Press

Now assemble the oil seal parts in the following

bearing assembly into bearing bore of adapter and

order: lock washer, back up washer, coil spring,

cover with tool shown in Figure 15.

back up washer, synthetic rubber ring.

7-4