TM 5-3895-359-14&P

g. Remove cotter pin and drive gear from shaft.

h. Remove key from shaft. Remove snap ring

adjacent to gear.

i. Remove driven gear and shaft. Remove

flange and adapter from vise or fixture and by

pressing on drive gear end of shaft, press out the

bearing. Be sure to coat drive shaft with white

lead, on area where pumps drive gear was

removed, to aid in sliding through the outboard

bearing.

j. Remove seal assembly and locating snap ring

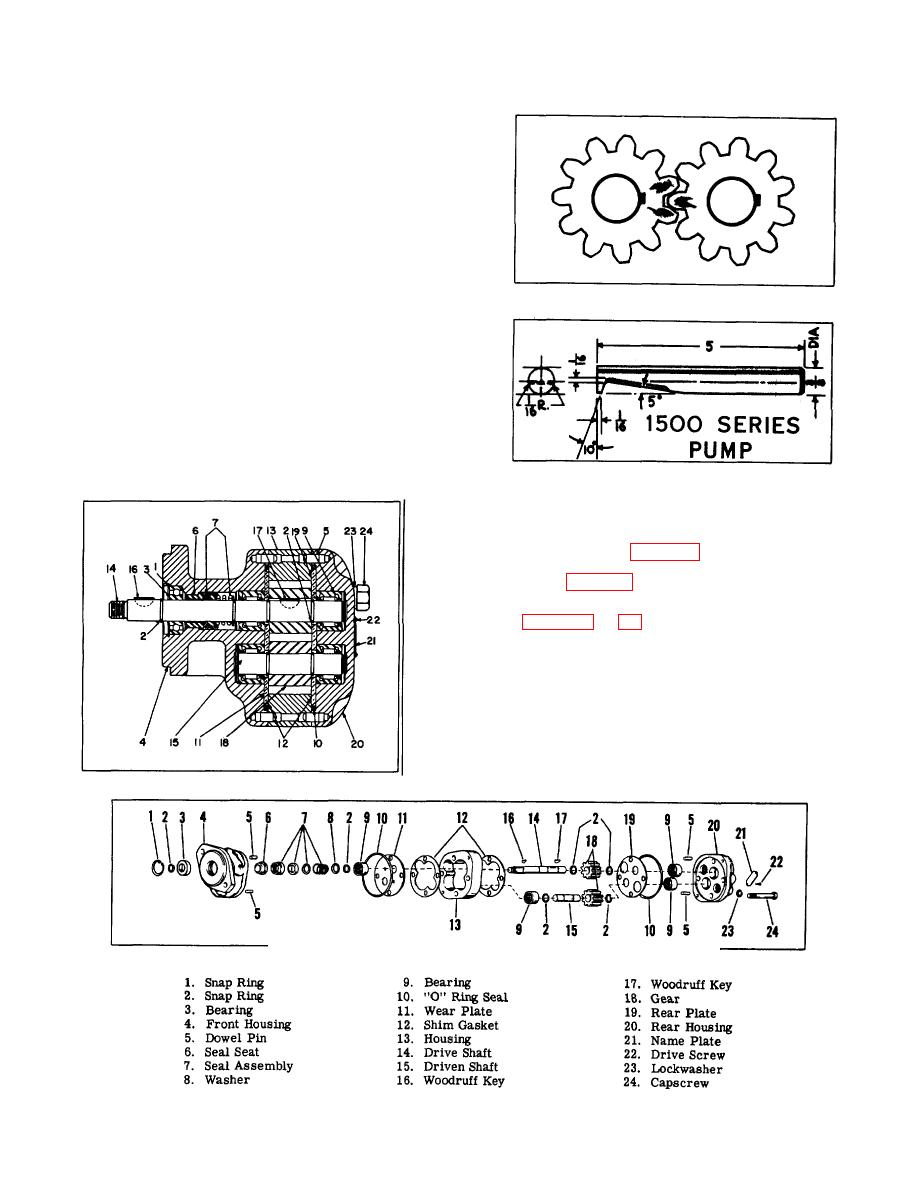

FIGURE 4 Marking of the Gears for Location

and washer from pump drive shaft.

k. Remove dowel pins from cover and adapter

castings, with a pliers or a lever jaw wrench.

NOTE:

Replace roller bearings only if

necessary and then only with the

same make and type as originally

installed.

l. Check bearings for freeness of rollers, pitted,

broken or excessively worn rollers.

Replace

FIGURE 5 Tool Dimensions

bearing, if it is possible to insert a

feeler of 0.020" between rollers. More gap indicates

rollers are worn excessively.

m.

Remove roller bearings by starting them with

tool shown in Figure 5. Insert tool under the

bearing and into the cored hole, behind bearing

bores, Figure 6.

n.

Complete removal of the bearing, using tool

bar.

o.

Remove outboard bearing retaining snap ring

with ring pliers.

p.

Reach down through the drive shaft bearing

bore with a brass drift punch and tap out the

outboard bearing. Tap opposite side alternately.

FIGURE 2

FIGURE 3 Exploded View of Hydraulic Pump

7-2