TM 5-3895-342-12

g. Installation. Install the magneto in reverse

(5) Check spark plug gap. Correct gap is

of the instructions in sub paragraph a above.

.030 inch.

4-25. Spark Plugs and Leads

(6) Test spark plug with a suitable tester.

a. Removal. Remove the spark plugs and

Replace defective spark plugs.

leads as instructed on figure 4-21.

c. Installation. Install spark plugs and leads in

reverse of instructions on figure 4-21. Tighten

spark plugs to 25 to 30 foot pounds torque.

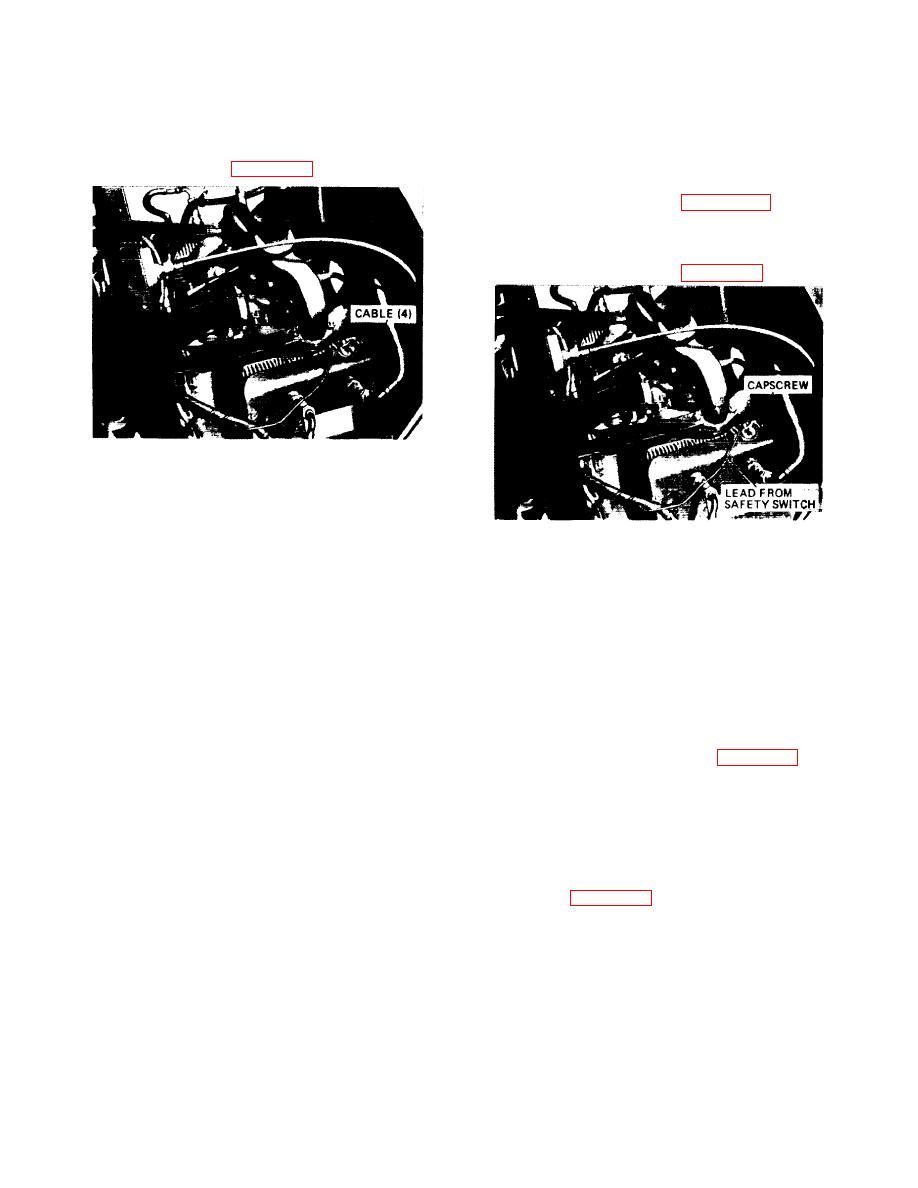

4-26. Hi-Temperature Safety Switch

a. Removal. Remove

the

hi-temperature

safety switch as instructed on figure 4-22.

1. LOOSEN NUT AND DISCONNECT CABLE (4).

2. REMOVE SPARK PLUGS (4).

ME 3895-342-12/4-21

Figure 4-21. Spark plugs and leads removal.

1. DISCONNECT LEAD FROM SAFETY SWITCH

b. Cleaning and Inspection.

AND FROM MAGNETO.

(1) Clean the spark plug leads with a cloth

2. REMOVE CAPSCREW AND WASHER AND

dampened in cleaning solvent and dry thoroughly.

SWITCH.

(2) Clean the spark plug electrodes by

ME3895-342-1 2/4-22

sand- blasting.

Figure 4-22. Hi-temperature safety switch and lead

(3) Inspect the spark plug electrodes for

removal.

burned or tapered condition. Replace defective

spark plugs.

b. Cleaning and Inspection.

(4) Inspect the spark plug lead sheeting for

(1) Clean all parts with a cleaning solvent.

cracks, breaks, or corrosion. Replace defective

(2) Inspect the switch for damage or

leads.

corrosion. Replace a defective switch.

c. Installation. Install the hi-temperature safety

switch in reverse of instructions on figure 4-22.

SECTION X. FUEL SYSTEM

.

air cleaner removes dirt and grit from the air,

4-27. General

passing clean air to the carburetor where it is mixed

The mixer is equipped with a gravity type fuel

with the fuel for proper combustion.

system. The fuel system consists of a fuel tank, air

4-28. Air Cleaner

cleaner, fuel strainer and shut-off valve, carburetor,

and governor. Fuel flows from the fuel tank into

a. Removal. Remove the air cleaner as

the fuel strainer where dirt and water in the fuel is

instructed on figure 4-23.

intercepted into a removable sediment bowl. From

the strainer the fuel flows into the carburetor. The

4-15