TM 5-3895-369-14

5-23. ROCKER ARM ASSEMBLY REPLACEMENT/REPAIR (CONT.).

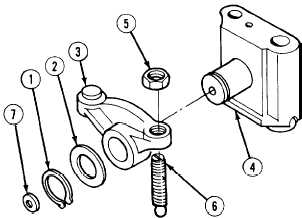

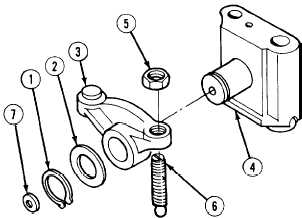

b. Disassembly.

NOTE

All six rocker arms are disassembled the

same way.

(1)

Remove two retaining rings (l), washers (2),

and rocker arms (3) from arm support (4).

(2)

Remove two nuts (5) and pushrod adjusting

screws (6).

(3)

If damaged, remove expansion plug (7) from

arm support (4).

c.

Cleaning/Inspection.

Compressed air used for cleaning purposes

must not exceed 30 psi (207 kPa). Use

only with effective chip guarding and

personal protective equipment

(goggles/shield, gloves, etc).

(1)

(2)

(3)

Clean all parts of rocker arm assembly in

strong detergent and hot water. Rinse in

clean hot water and use compressed air to

dry all parts.

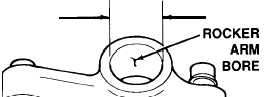

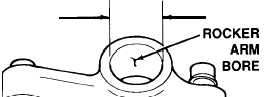

.7480 to .7500 in. (19 to 19.051 mm)

I

Check rocker arm for cracks, excessive wear,

and other damage. Replace all rocker arms

failing inspection.

Measure rocker arm bore as indicated. Normal measurement is 0.7480 to 0.7500 in. (19 - 19.051 mm). If

above or below normal measurement, replace rocker arm.

5-170