TM 5-3895-369-14

(a)

(b)

(c)

(d)

(e)

(11)

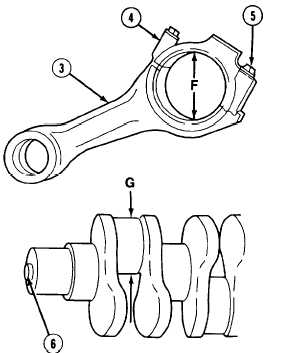

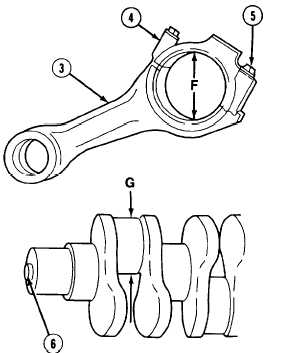

Determine rod bearing clearance for each

rod as follows:

Install six rod caps (4) on connecting

rods (3) with 12 screws (5). Tighten

screws 73 lb-ft (99 N-m).

Measure each connecting rod (3) at

position F. Record smallest diameter.

Measure crankshaft (6) at position G

for each rod (3). Normal measurement

is 2.7150 to 2.7170 in. (68.962 -

69.013 mm).

Add smallest crankshaft and connecting

rod measurements. Clearance should

be no greater than 0.0035 in.

(0.089 mm).

If rod bearing clearance exceeds

measurement limit, replace bearings. If

clearance still exceeds measurement

limit, replace connecting rod and

rod cap.

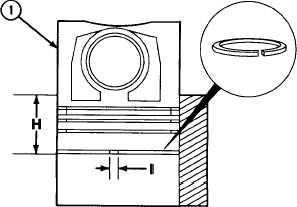

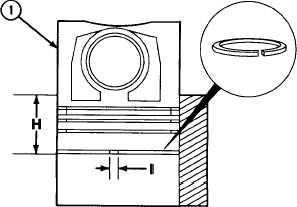

NOTE

To ensure proper measurement of rings,

install rings with printed side up.

(12)

Install each ring in cylinder approximately

3.5 in. (89 mm) deep (position H). Level

ring using piston (1).

(13)

Remove piston (1) and measure each ring

gap at position I. If below or above limits,

replace ring. Normal measurements are as

follows:

(a)

Top ring is 0.0160 to 0.0275 in. (0.40 -

0.70 mm).

(b)

Intermediate ring is 0.0100 to 0.0215 in.

(0.25 - 0.55 mm).

(c)

Oil control ring is 0.0100 to 0.0215 in.

(0.25 - 0.55 mm).

5-165