TM 5-3895-369-14

4-83. ENGINE OIL PRESSURE SWITCH REPLACEMENT.

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Equipment Condition

Tools

Condition Description

TM or Para

Tool kit, general mechanics: automotive

Left engine door open.

Wrench, torque

General Safety Instructions

If engine has recently been in operation, allow

Materials/Parts

time for cooling before performing procedure.

Compound, thread locking (item 15, appendix E)

Lockwasher

a.

Removal.

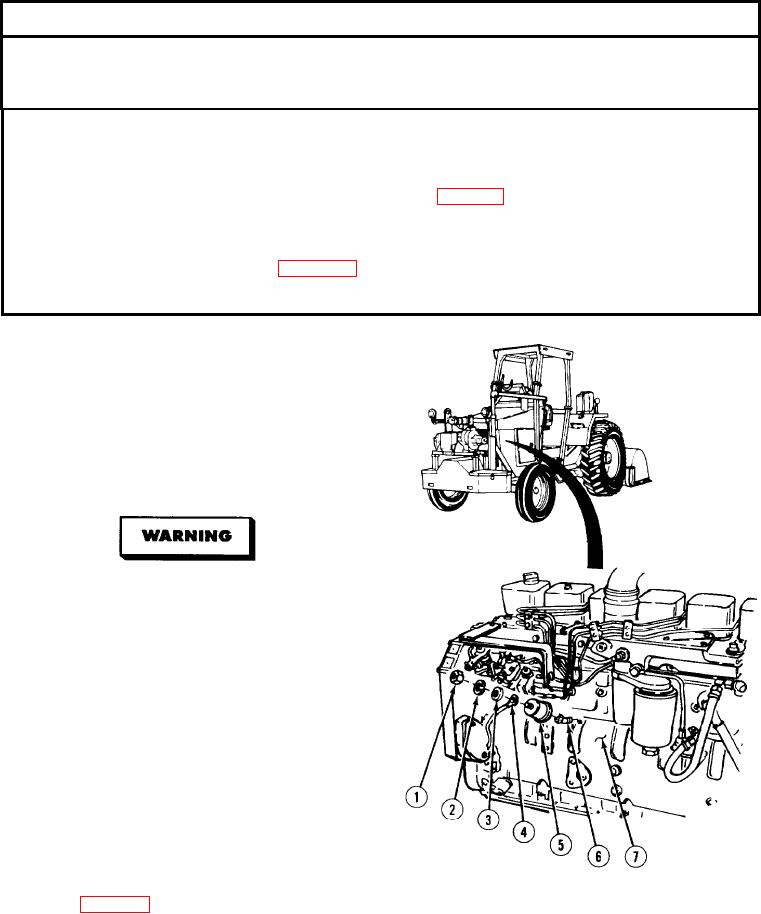

(1) Remove nut (l), lockwasher (2), washer (3),

wire (4), and oil pressure switch (5) from

elbow pipe (6). Discard lockwasher.

(2) If damaged, remove elbow pipe (6) from

engine block (7).

b. Installation.

Adhesive sealant MIL-S-45163 can damage

your eyes. Wear safety goggles/glasses

when using; avoid contact with eyes. If

sealant contacts eyes, flush eyes with water

and get immediate medical attention.

(1) If removed, apply thread locking compound

to threads of elbow pipe (6) and install

elbow pipe on engine block (7).

(2) Install oil pressure switch (5) on elbow

pipe (6). Tighten switch 144 lb-in (16 Nm).

(3) Install wire (4) washer (3), lockwasher (2),

and nut (1) on oil pressure switch (5).

NOTE

Follow-on maintenance: Close left engine

door (para 2-14).

END OF TASK

4-327