TM 5-3895-369-14

4-47. FUEL LINES AND FITTINGS REPLACEMENT (CONT).

b. Cleaning/Inspection.

Drycleaning solvent (P-D-680) is TOXIC and flammable. Wear protective goggles and gloves; use

only in well-ventilated area; avoid contact with skin, eyes, and clothes, and do not breathe vapors.

Keep away from heat or flame. Never smoke when using solvent; the flashpoint for type I

drycleaning solvent is 100F (38C) and for type II is 140F (60C). Failure to do so may result in

injury or death to personnel.

If personnel become dizzy while using drycleaning solvent, immediately get fresh air and medical

help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts eyes, immediately

flush eyes with water and get immediate medical attention.

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use only with effective

chip guarding and personal protective equipment (goggles/shield, gloves, etc).

(1) Clean banjo screws with drycleaning solvent. Dry with compressed air.

(2) Flush fuel tubes with drycleaning solvent. Dry with compressed air.

(3) Wipe off fuel tubes with lint-free cloth and inspect tubes for holes, dents, and other damage.

(4) Inspect tee, adaptors, and screws for

thread bareness.

(5) Replace all damaged parts.

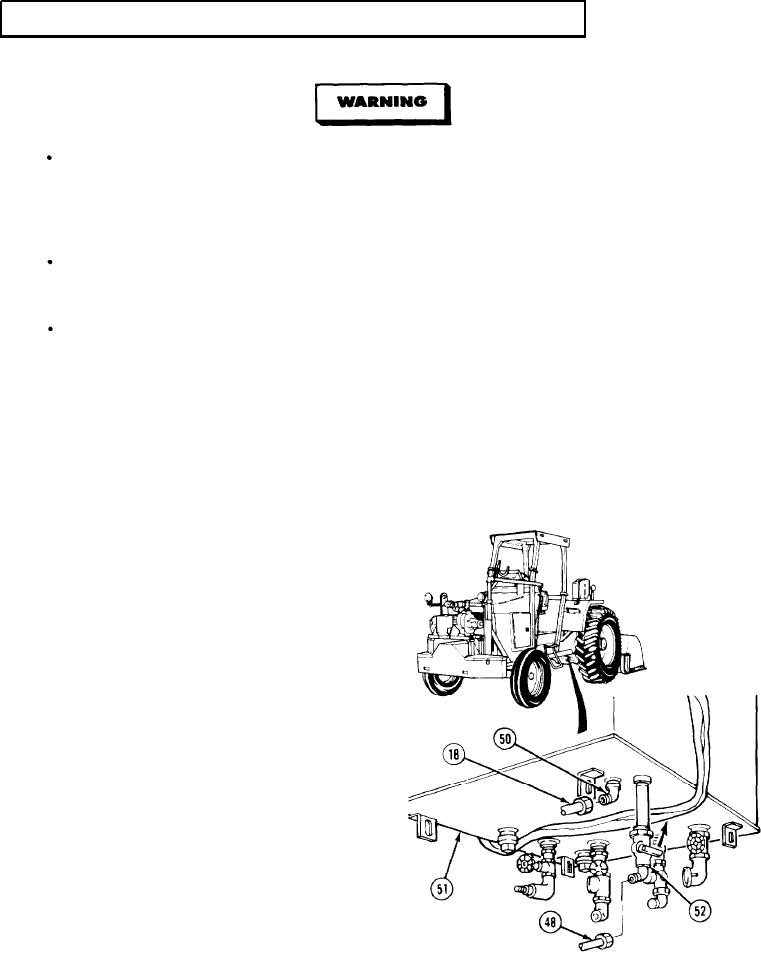

Installation.

c.

NOTE

Fuel hose to sediment bowl is installed in

step (2). Fuel return hose is installed in

step 5(g).

(1) Install fuel hoses on fuel tank as follows:

(a) Install fuel hose (48) on shutoff

valve (52).

(b) Install fuel return hose (18) on

fitting (50).

NOTE

Do not perform step l(c) until procedure

is completed.

(c) Turn shutoff valve (52) on fuel

tank (51) in opposite direction to turn

fuel on.

4-212