TM 5-3895-369-14

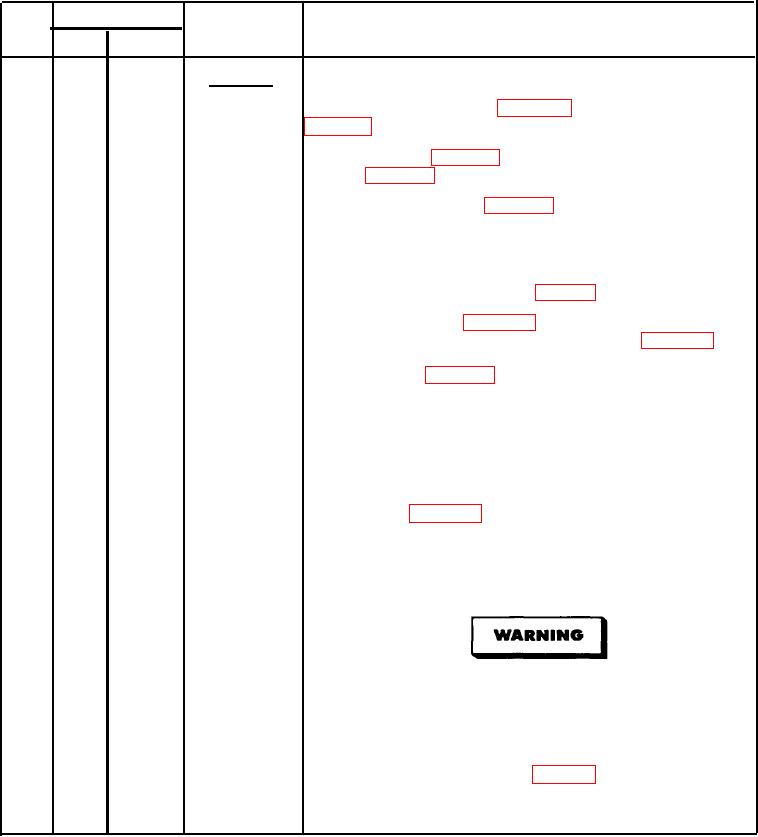

Table 4-2. Unit Preventive Maintenance Checks and Services

Hr - Hours

MO - Months

Item to Be

Interval

Item

Procedure

Inspected

Hr

No.

MO

ENGINE

Change the lube oil and filter (paras 4-24 and 4-35). Refer to

Engine

3

250

1

Chapter 3, Section I.

Change fuel filters (para 4-52). Bleed fuel system if

Fuel filters

500

6

2

required (para 4-54).

Adjust valve lash clearance (para 4-30):

Valves

12

1000

3

Intake - 0.010 in. (0.254 mm)

Exhaust - 0.020 in. (0.508 mm)

Check the anti-freeze concentration. Add enough anti-freeze to

Radiator

6

500

4

protect the engine to -24F (-31C) (para 3-7).

Drain the cooling system (para 4-66). Check for damaged hoses, and

Cooling system

5

12

1000

loose or damaged hose clamps. Replace as required (para 4-62).

Check radiator for leaks, damage, and build-up of dirt. Clean and

repair as required (para 4-60). Flush the system until the water is

clean. Use a mixture of 50% water and 50% anti-freeze. System

capacity is 6 gal. (23 I).

Check the belt deflection at the longest span of belt. Maximum

Drive belt,

1000

6

12

deflection is 5/8 to 1/2 in. (9.5 - 12.7 mm). Replace belt if required

tensioner

bearing, and fan

(4-68). Check the tensioner and fan hub bearings. Should spin freely

with no rough spots, wobble, or end play. Replace tensioner or fan

hub

hub if required (paras 4-69 and 4-67).

Check the index lines on the damper hub and the inertia member. If

Vibration

2000

7

24

the lines are more than 1/16 in. (1.59 mm) out of alignment, notify

damper

direct support maintenance.

If NBC exposure is suspected, all air filter media should

be handled by personnel wearing protective equipment.

Consult your unit NBC Officer or NBC NCO for

appropriate handling or disposal procedures.

Check/inspect air cleaner element (para 3-8). Tighten or replace

Air cleaner/

250

8

3

parts as necessary to make sure air intake system does not leak (i.e.

intake system

cracked hoses, loose clamps, punctures, etc.).

4-10