TM 5-3895-359-14&P

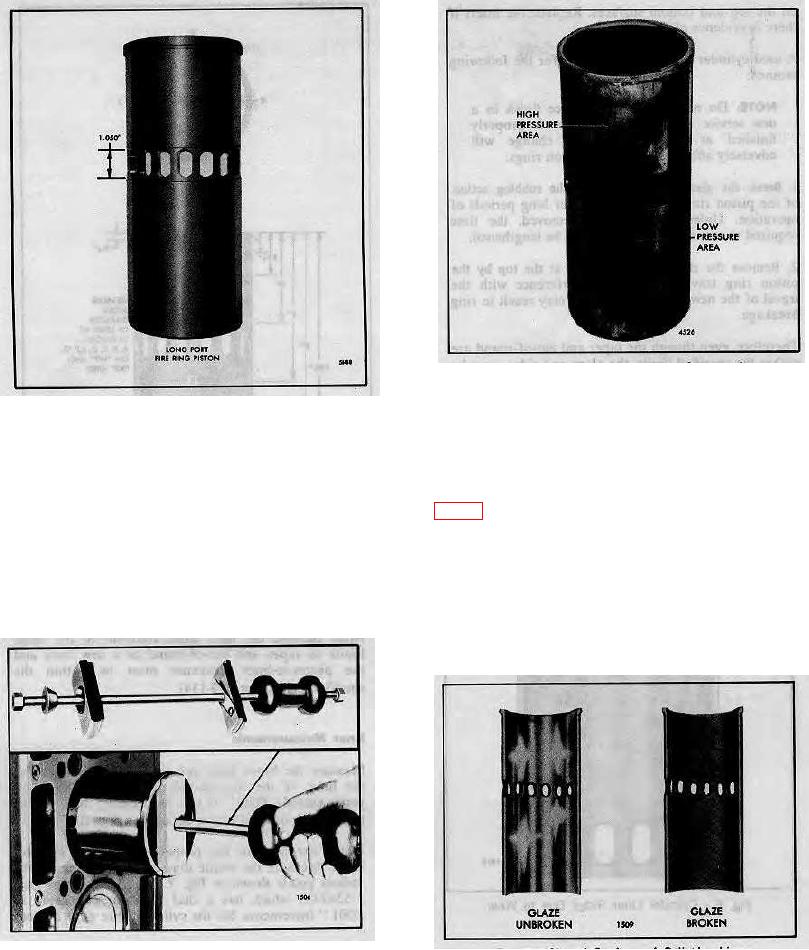

Fig. 4 - High and Low Pressure Contact Areas

on Cylinder Liner

Fig. 2 -Cylinder Liner

Excessive liner-to-block clearance or block bore

Inspect Used Cylinder Liner

distortion will reduce heat transfer from the liner to the

block and to the engine coolant. Poor contact between

When the cylinder liner is removed from the cylinder

the liner and the block bore may be indicated by stains

block, it must be thoroughly cleaned and then checked

or low pressure areas on the outer surface of the liner

for:

Cracks

Inside diameter

Examine the outside diameter of the liner for fretting.

Scoring

Outside diameter

Fretting is the result of a slight movement of the liner in

Poor contact on outer surface

Out-of-round

the block bore during engine operation, which causes

Flange irregularities

Taper

material from the block to adhere to the liner. These

A cracked or excessively scored liner must be

metal particles may be removed from the surface of the

discarded. A slightly scored liner may be cleaned-up

liner with a coarse, flat stone.

and reused.

The liner flange must be smooth and flat on both the top

and bottom surfaces. Check for cracks at the flange.

The liner insert must also be smooth and flat

Fig. 3. Removing Cylinder Liner.

Fig. 5. Glazed Surface of Cylinder Liner.

10-2-93