TM 5-3895-359-14&P

INJECTOR TIMING

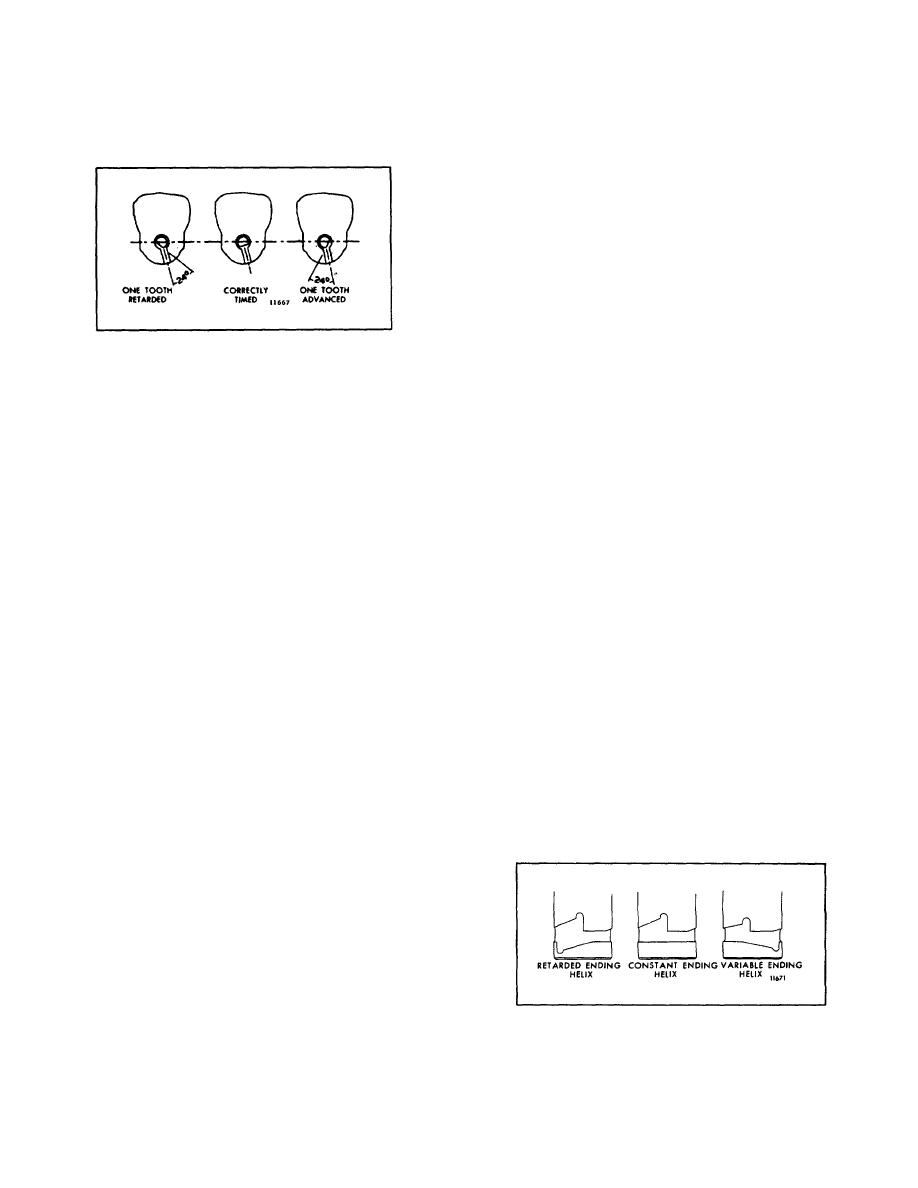

If it is suspected that a fuel injector is "out of time", the

injector rack-to-gear timing may be checked without

disassembling the injector.

A hole located in the injector body, on the side opposite

the identification tag, may be used to visually determine

whether or not the injector rack and gear are correctly

timed. When the rack is all the way in (full-fuel

position), the flat side of the plunger will be visible in the

hole, indicating that the injector is "in time". If the flat

side of the plunger does not come into full view (Fig. 3)

Fig. 3 Injector Rack-to-Gear Timing

and appears in the "advanced" or "retarded" position,

disassemble the injector and correct the rack-to-gear

timing.

INJECTOR SPRAY TIPS

Due to a slight variation in the size of the small orifices

Flow gage J 25600 may be used to select a spray tip

in the end of each spray tip, the fuel output of an injector

that will increase or decrease fuel injector output for a

may be varied by replacing the spray tip.

particular injector after it has been rebuilt and tested on

the calibrator.

EFFECT OF PRE-IGNITION ON FUEL INJECTOR

Pre-ignition is due to ignition of fuel or lubricating oil in

Before replacing the injectors, check the engine for the

the combustion chamber before the normal injection

cause of pre-ignition to avoid recurrence of the problem.

period. The piston compresses the burning mixture to

Check for oil pull-over from the oil bath air cleaner,

excessive temperatures and pressures and may

damaged blower housing gasket, defective blower oil

eventually cause burning of the injector spray tip and

seals, high crankcase pressure, plugged air box drains,

lead to failure of the injectors in other cylinders.

ineffective oil control rings or dilution of the lubricating

oil.

When pre-ignition occurs, remove all of the injectors

and check for burned spray tips or enlarged spray tip

orifices.

INJECTOR PLUNGERS

The fuel output and the operating characteristics of an

the hardened case and result in chipping at the helices

and seizure or scoring of the plunger.

injector are, to a great extent, determined by the type of

plunger used. Three types of plungers are illustrated in

Fig. 4. The beginning of the injection period is

controlled by the upper helix angle. The lower helix

angle retards or advances the end of the injection

period. Therefore, it is imperative that the correct

plunger is installed whenever an injector is overhauled.

If injectors with different type plungers (and spray tips)

are mixed in an engine, erratic operation will result and

may cause serious damage to the engine or to the

equipment which it powers.

Injector plungers cannot be reworked to change the

Fig. 4 Types of Injector Plungers

output or operating characteristics. Grinding will destroy

10-3-54