TM 5-3895-359-14&P

If an injector tester supply or gage line is damaged or

Occasionally dirt will get into the pump check valve in

broken, install a new replacement line (available from

the tester, resulting in internal pump valve leakage and

the tester manufacturer). Do not shorten the old lines or

the inability to build up pressure in the tester fuel

the volume of test oil will be altered sufficiently to give

system. Pump valve leakage must be corrected before

an inaccurate valve holding pressure test.

an injector can be properly tested.

If it is suspected that the lines have been altered, i.e. by

When the above occurs, loosen the fuel inlet connector

shortening or replacing with a longer line, check the

clamp and operate the tester pump handle in an attempt

accuracy of the tester with a master injector on which

to purge the dirt from the pump check valve. A few

the pressure holding time is known. If the pressure

quick strokes of the pump handle will usually correct a

holding time does not agree with that recorded for the

dirt condition. Otherwise, the pump check valve must

master

injector,

replace

the

lines.

be removed, lapped and cleaned or replaced (J 9787).

The pump check valve must be replaced on tester J

23010.

REFINISH LAPPING BLOCKS

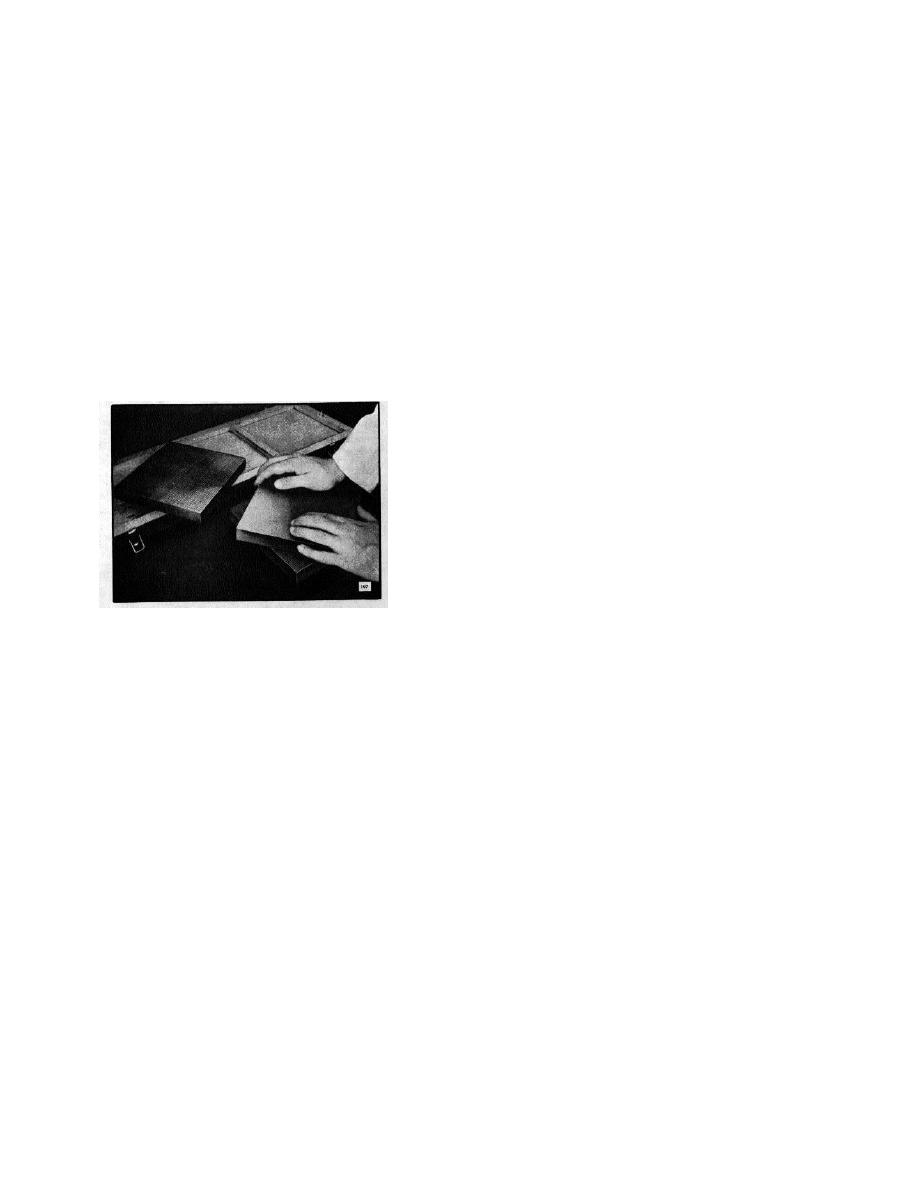

To refinish the blocks, spread some 600 grit lapping

powder of good quality on one of the blocks. Place

another block on top of this one and work the blocks

together as shown in Fig. 2. Alternate the blocks from

time to time. For example, assuming the blocks are

numbered 1, 2 and 3, work I and 2 together, then I and

3, and finish by working 2 and 3 together. Continue this

procedure until all of the blocks are perfectly flat and

free of imperfections.

Imperfections are evident when the blocks are clean and

held under a strong light. The blocks are satisfactory

Fig. 2 Refinishing Lapping Blocks

when the entire surface is a solid dark gray. Bright or

exceptionally dark spots indicate defects and additional

lapping is required.

As the continued use of the lapping blocks will cause

worn or low spots to develop in their lapping surfaces,

After the surfaces have been finished, remove the

they should be refinished from time to time.

powder by rinsing the lapping blocks in trichloroethylene

and scrubbing with a bristle brush.

It is good practice, where considerable lapping work is

done, to devote some time each day to refinishing the

When not in use, protect the lapping blocks against

blocks. The quality of the finished work depends to a

damage and dust by storing them in a close fitting

great degree on the condition of the lapping surfaces of

wooden container.

the blocks.

MASTER INJECTOR CALIBRATING KIT

Use Master Injector Calibrating Kit J 26298 to determine

Injector testing can be carried out now without any

the accuracy of the injector calibrator.

adjustment of figures. However, when testing new

injectors for output, any difference between the

With the test fluid temperature at 100 1 (38 1

F

C

calibrator and the masters should be used to compute

and each injector warm after several test cycles, run

)

new injector calibration. If more than a 2% variation

the three injectors contained in the kit. Several readings

from the masters is noted, consult the calibrator

should be taken with each injector to check for accuracy

manufacturer for possible causes.

and repeatability. If the output readings are within 2% of

the values assigned to the calibrated masters, the

The calibrated masters should only be used to qualify

calibrator can be considered accurate.

injector output calibration test equipment.

10-3-53