TM 5-3895-359-14&P

TROUBLE SHOOTING

FUEL PUMP

The most common reason for failure of a fuel pump to

The fuel pump is so constructed as to be inherently

function properly is a sticking relief valve. The relief

trouble free. By using clean, water-free fuel and

valve, due to its close fit in the valve bore, may become

maintaining the fuel filters in good condition, the fuel

stuck in a fully open or partially open position due to a

pump will provide long satisfactory service and require

small amount of grit or foreign material lodged between

very little maintenance.

the valve and its bore or seat. This permits the fuel to

circulate within the pump rather than being forced

However, if the fuel pump fails to function satisfactorily,

through the fuel system.

first check the fuel level in the fuel tank, then make sure

the fuel supply valve is open. Also check for external

Therefore, if the fuel pump is not functioning properly,

fuel leaks at the fuel line connections and filter gaskets.

remove the relief valve plug, spring and pin and check

Make certain that all fuel lines are connected in their

the movement of the valve within the valve bore. If the

proper order.

valve sticks, recondition it by using fine emery cloth to

remove any scuff marks. Otherwise, replace the valve.

Next, check for a broken pump drive shaft or drive

Clean the valve bore and the valve components. Then

coupling. Insert the end of a wire through the pump

lubricate the valve and check it for free movement

flange drain hole, then crank the engine momentarily

throughout the entire length of its travel. Reinstall the

and note whether the wire vibrates. Vibration will be felt

valve.

if the pump shaft rotates.

After the relief valve has been checked, start the engine

All fuel pump failures result in no fuel or insufficient fuel

and check the fuel flow at some point between the

being delivered to the fuel injectors and may be

restricted fitting in the fuel return manifold at the

indicated by uneven running of the engine, excessive

cylinder head and the fuel tank.

vibration, stalling at idling speeds or a loss of power.

CHECKING FUEL FLOW

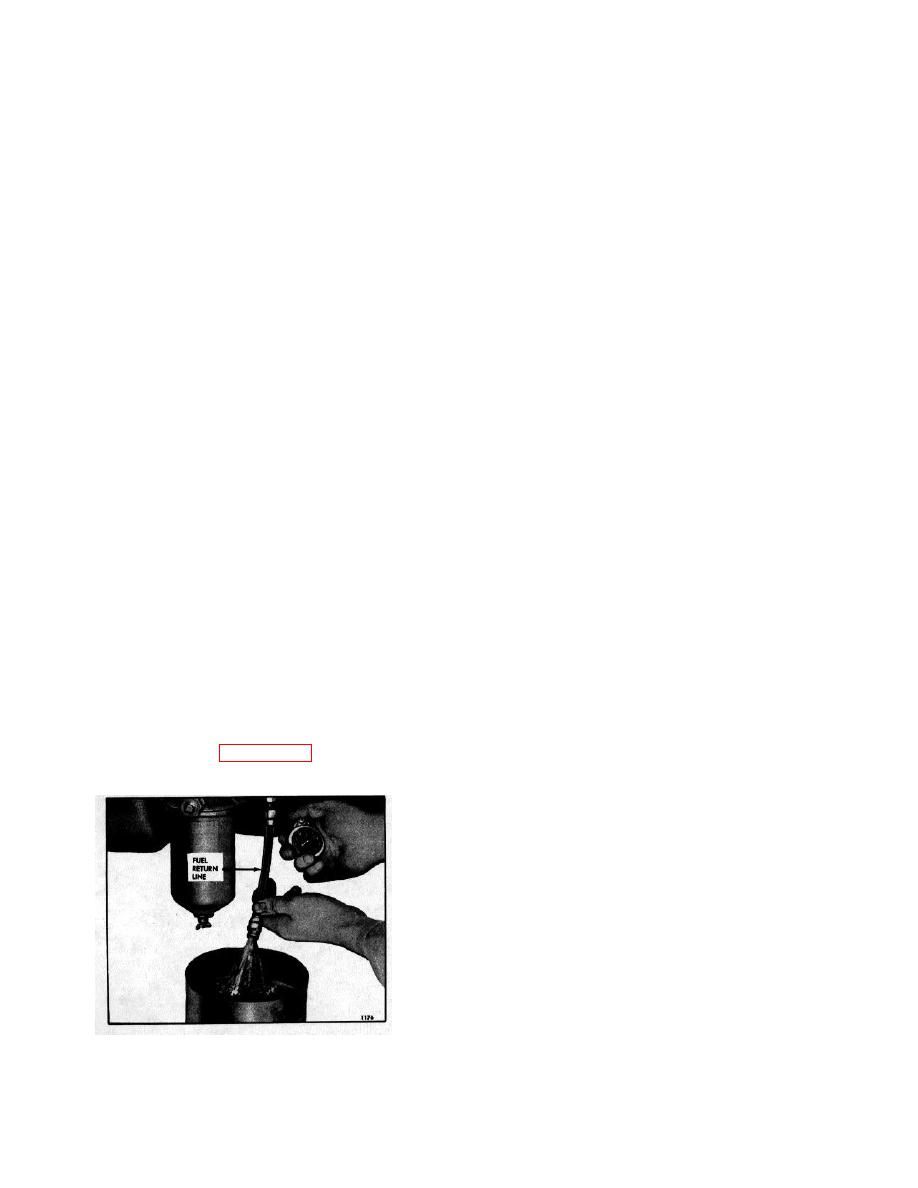

1. Disconnect the fuel return hose from the fitting at the

3. Immerse the end of the fuel hose in the fuel in the

fuel tank and hold the open end in a convenient

container. Air bubbles rising to the surface of the fuel

receptacle (Fig. 6).

will indicate air being drawn into the fuel system on the

suction side of the pump. If air is present, tighten all

2. Start and run the engine at 1200 rpm and measure

fuel line connections between the fuel tank and the fuel

the fuel flow. Refer to Page 10-9-1 for the specified

pump.

quantity per minute.

4. If the fuel flow is insufficient for satisfactory engine

performance, then:

a. Replace the fuel strainer cartridge. Then start the

engine and run it at 1200 rpm to check the fuel flow. If

the flow is still unsatisfactory, perform Step "b" below:

b. Replace the fuel filter cartridge. If the flow is still

unsatisfactory, do as instructed in Step "c".

c. Substitute another fuel pump that is known to be in

good condition and again check the fuel flow. When

changing a fuel pump, clean all of the fuel lines with

compressed air and be sure all fuel line connections are

tight. Check the fuel lines for restrictions due to bends

or other damage.

Fig. 6 Measuring Fuel Flow

10-3-57