TM 5-3895-359-14&P

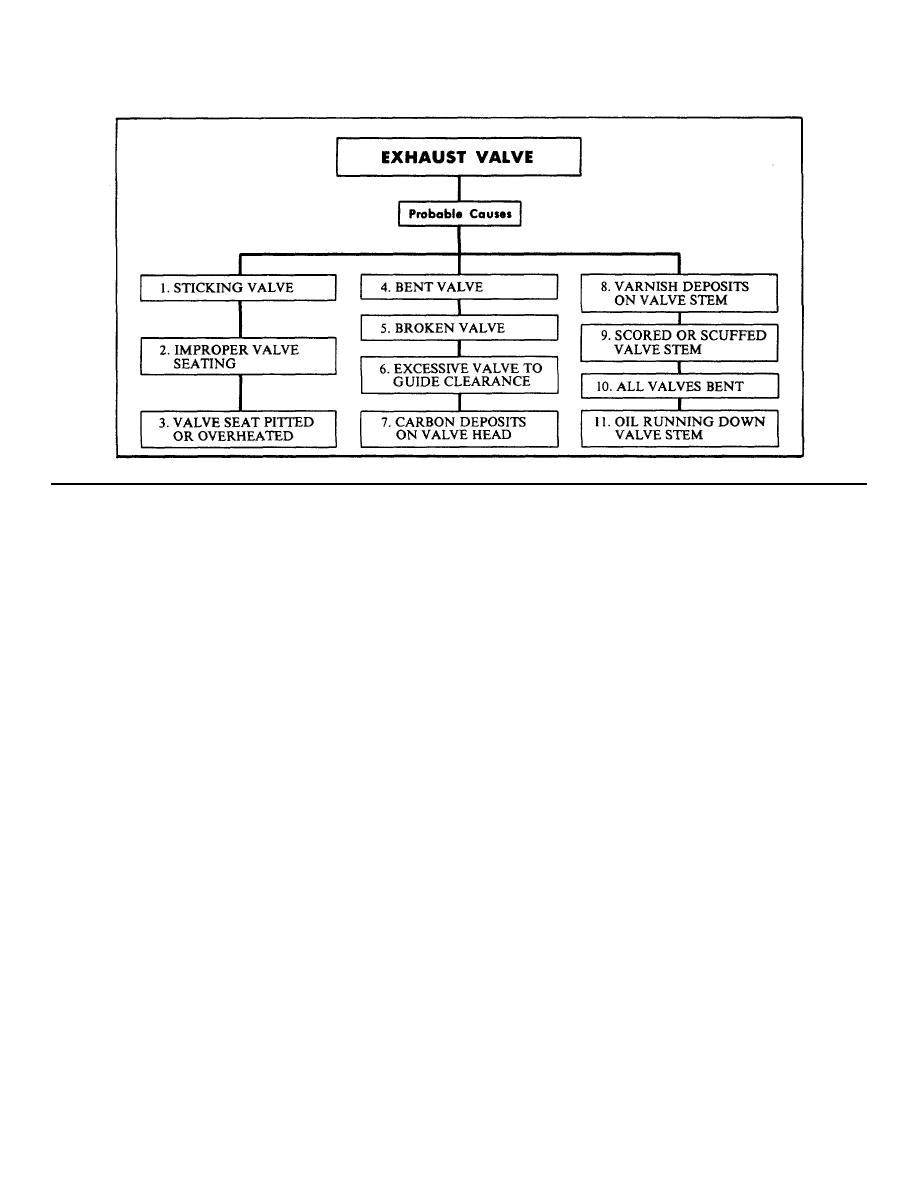

TROUBLE SHOOTING

SUGGESTED REMEDY

7.

Black carbon deposits extending from the valve

1.

Check for carbon deposits, a bent valve guide,

seats to the guides indicates cold operation due to light

defective spring or antifreeze (glycol) in the lubricating

loads or to the use of too heavy a fuel. Rusty brown

oil. Replace a bent guide. Clean-up and reface the

valve heads with carbon deposits forming narrow collars

valve. Replace the valve if necessary.

near the guides indicate hot operation due to overloads,

inadequate cooling or improper timing which results in

2.

Check for excessive valve-to-guide clearance,

carbonization of the lubricating oil. Clean-up the valves,

bent valve guide or carbon deposits. Replace a bent or

guides and inserts. Reface the valves and inserts or

worn guide. Clean the carbon from the valve. Reface

replace them if they are warped, pitted or scored.

or replace the valve, if necessary.

8.

Check for a worn valve guide or excessive

3.

Check the operating conditions of the engine for

exhaust back pressure. Replace a worn guide. Check

overload, inadequate cooling or improper timing.

the valve seat for improper seating. Reface the valve

Reface the valve and insert. Replace the valve if it is

and insert or, if necessary, replace.

warped or too badly pitted. Use a harder-face valve if

the operating conditions warrant.

9.

Check for a bent valve stem or guide, metal chips

or dirt, or for lack of lubrication. Clean up the valve

4.

Check for contact between the valve head and the

stem with crocus cloth wet with fuel oil or replace the

piston as a result of incorrect valve clearance, or a

valve. Replace the guide. When installing a valve, use

defective spring. Check the valve guide, insert, cylinder

care in depressing the spring so that the spring cap

head and piston for damage. Replace damaged parts.

DOES NOT scrape the valve stem.

5.

Check for excessive valve-to-guide clearance, a

10. Check for a gear train failure or for improper gear

defective valve spring or etching of the valve stem at

train timing.

the weld. Improper valve clearance is also a cause of

this type of failure. Check the guide, insert, cylinder

11. Check the operation of the engine for excessive

head and piston for damage. Replace damaged parts.

idling and resultant low engine exhaust back pressure.

Install valve guide oil seals.

6.

Replace a worn valve guide. Check and replace

the valve, if necessary.

10-2-132