TM 5-3895-359-14&P

WHEEL BEARING ADJUSTMENT

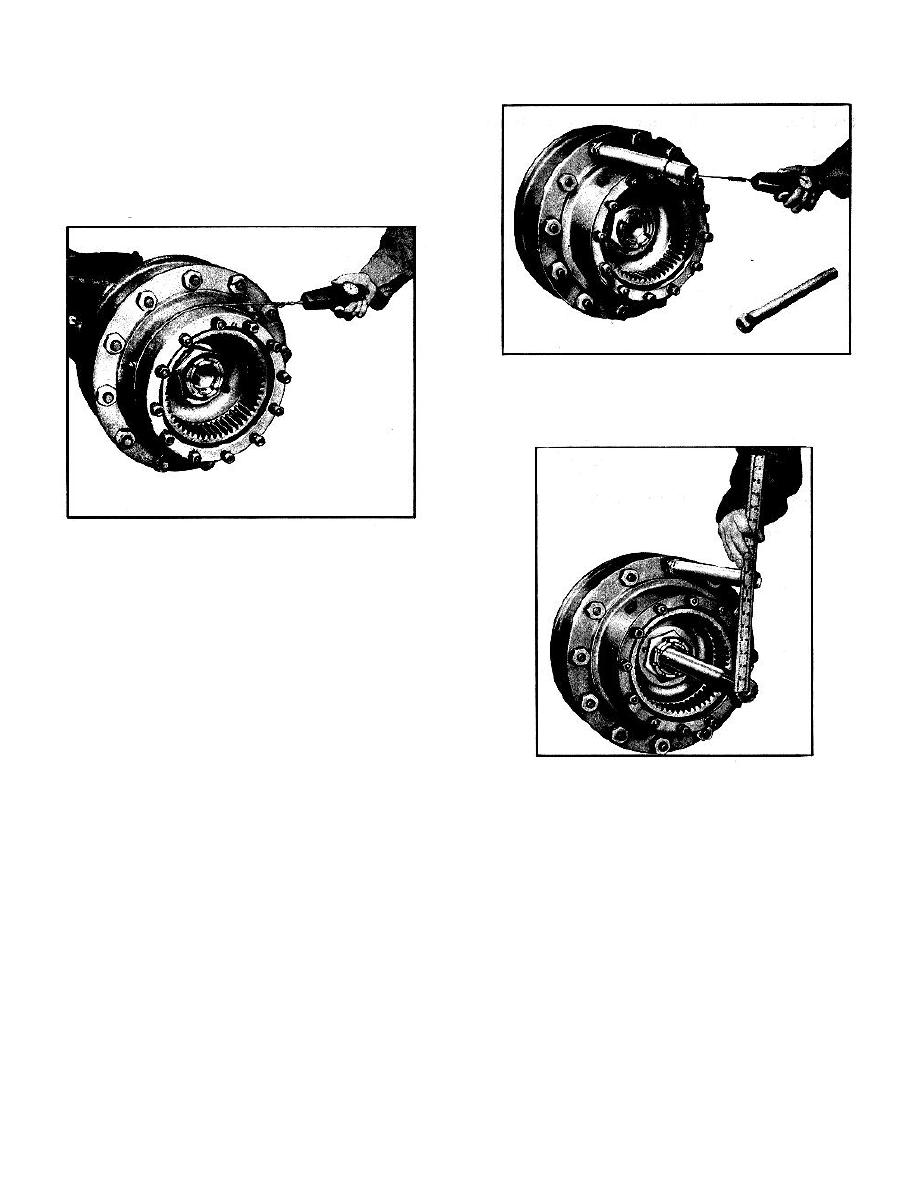

a. Tighten the adjusting nut against the ring gear

hub to 100 pound feet while wheel is being rotated.

Rotate the wheel in both directions to make sure

bearings and related parts are fully seated.

b. Back off adjusting nut / turn to relieve pre-load

on bearings.

d. If it is not convenient to remove the wheels of

the vehicle, check the wheel bearing preload torque.

The extension (see inset) permits a reading to be taken

without interference from the tire.

c. If wheel bearings have been replaced with new

by means of a pull scale and cord and advance the

adjusting nut in small increments until the proper

preload is obtained. The proper preload torque is 5 to 9

lb. ft.

NOTE

The above torque specification

allows for the drag of the hub

spindle oil seal. However, if a felt

dust seal is used in the inside of the

brake drum, the torque specifications

should be increased by 5 lb. It. If

wheel bearings are being reused,

e. Bearing preload torque is figured by multiplying

they should be put back in same

the radius (the distance from the center of the wheel to

position as before.

Advance the

the center of the extension) by the reading on the pound

adjusting nut in small increments

scale.

and check rotating torque until an

For Example: Assume the distance from the center of

increase is noted.

If increase is

the wheel to the center of the extension is 9 inches and

slight, install nut lock in this position

the reading on the pound scale is 7 pounds - multiplying

or back off nut enough to install nut

9 inches by 7 pounds, we get 63 pound inches. Since

our preload specifications are listed in pound feet, we

lock. If increase is appreciable, back

simply divide the 63 pound inches by 12 and arrive at a

off nut until increase is only slight or

reading of 5.25 pound feet.

none and then install nut lock, with

This method of converting pound inches to pound feet

two capscrews and lock plate.

also applies to Step "c" above.

5-5