TM 5-3895-359-14&P

B.

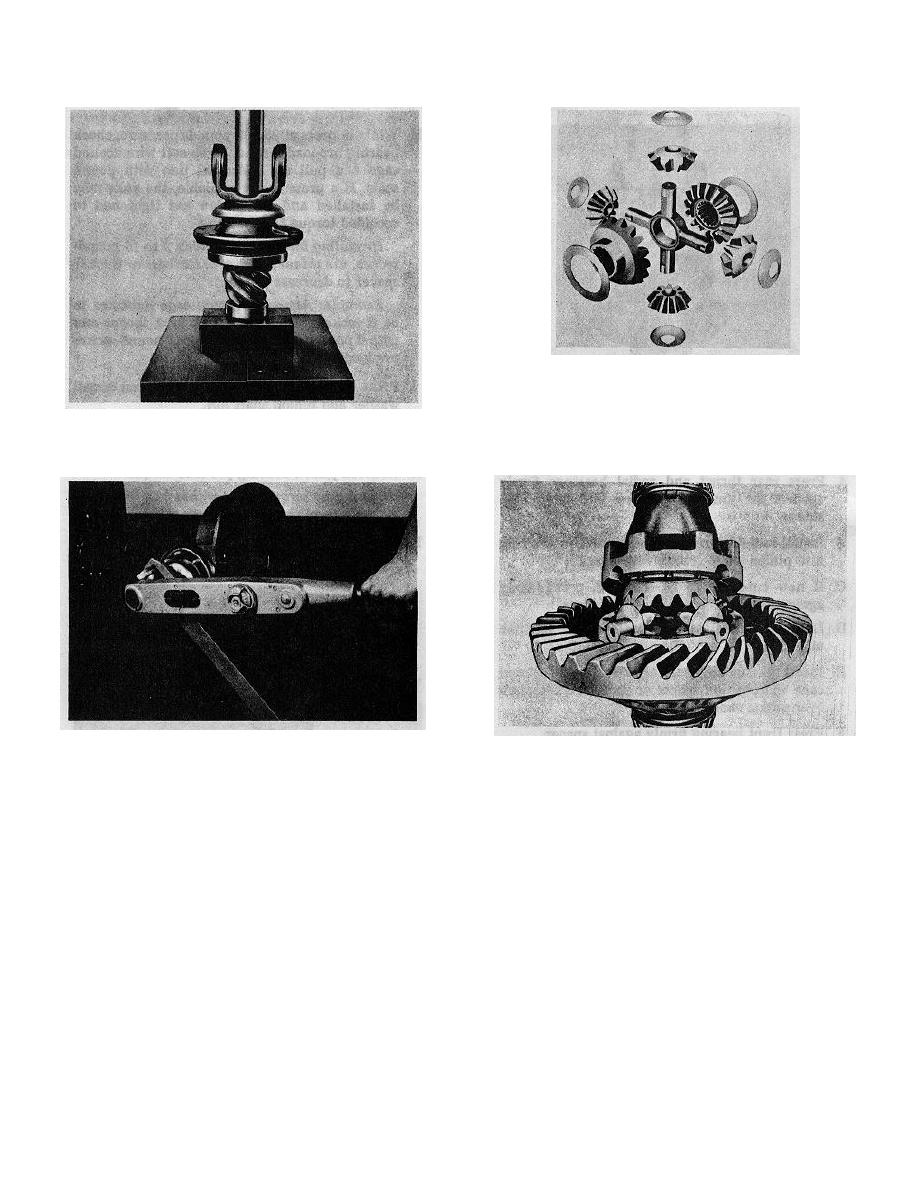

Lubricate differential case inner walls and all

component parts with axle lubricant.

C. Position thrust washer and side gear in bevel gear

and case half assembly.

O.

Press yoke against forward bearing and install

D. Place spider with pinions and thrust washers in

washer and pinion shaft nut.

position.

P. Tighten to specified torque and install cotter key. Do

E. Install component side gear and thrust washer.

not back off nut to align cotter key holes.

ASSEMBLE DIFFERENTIAL AND BEVEL GEAR

F. Align mating marks, position component case half

A. Rivet bevel gear to case half with new rivets.

and draw assembly together with four bolts or cap

If a new gear or differential case is to be used in

screws equally spaced.

the assembly, the rivet holes in the gear and case

G. Check assembly for free rotation of differential gears

should be checked for alignment and line reamed if

and correct if necessary.

necessary. The gear must be tight on the case pilot and

H. Install remaining bolts or cap screws, tighten to

riveted flush with the differential case flange. Check

specified torque and thread with lock wire.

with a .002" feeler gauge.

I. If bearings are to be replaced, press squarely and

Rivets should not be heated, but should be up set

firmly on differential case halves.

cold. When the correct rivet and rivet set is used the

head being formed will be at least As" larger in diameter

DIFFERENTIAL BEARING PRE-LOAD AND GEAR

than the rivet hole.

LASH ADJUSTMENTS

The head will then be approximately the same

The differential bearing pre-load and gear-lash

height as the preformed head. The formed head should

adjustments are obtained by the use of hardened and

not exceed /]6t" less than the preformed head as

ground spacers of the correct thickness located between

excessive pressure will cause distortion of the case

the differential bearing cups and the axle housing. On

holes and result in gear eccentricity.

this type assembly, no shim pack is required between

the pinion cage and axle housing.

4-18