TM 5-3895-359-14&P

H.

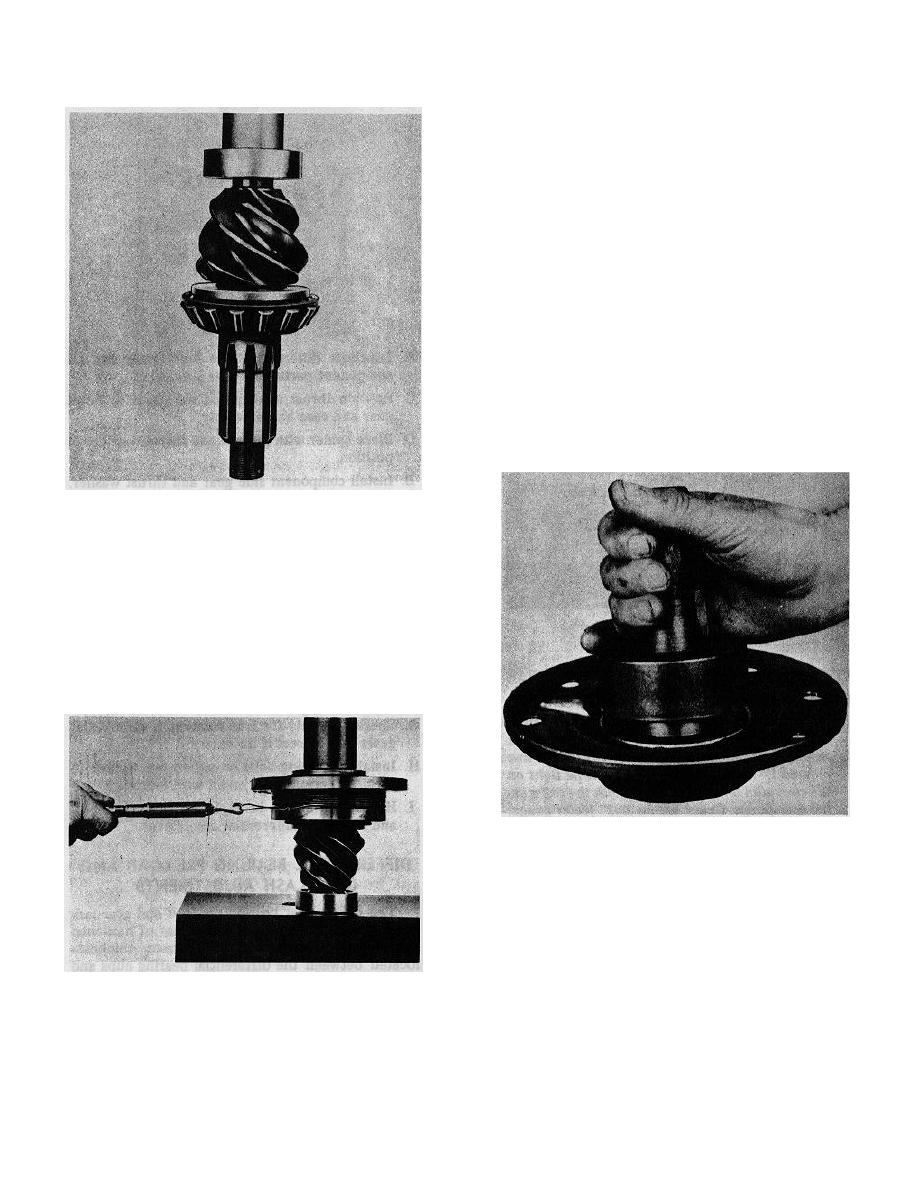

While in press at 25,000 pounds pressure, check

bearing pre-load torque. Wrap soft wire around

cage and pull on horizontal line with pound scale. If

a press is not available, the yoke may be installed

and the pinion nut tightened to specified torque for

checking.

If rotating torque is not within 5 to 15 pound-

inches, use thinner spacer to increase or thicker spacer

to decrease pre-load.

Example: Assuming pinion cage diameter to be 6

inches the radius would be 3 inches and with 5 pounds

pull would equal 15 pound-inches pre-load torque.

I. Press yoke against forward bearing and install washer

and pinion shaft nut.

J. Place pinion and cage assembly over carrier studs,

hold yoke and tighten pinion shaft nut to specified

torque. The yoke must be held with a suitable tool

or fixture to tighten nut.

K. Recheck pinion bearing pre-load torque. If rotating

torque is not within 5 to 15 pound-inches, repeat the

foregoing procedure.

L. Hold yoke and remove pinion shaft nut and yoke.

A. Press rear thrust and radial bearings firmly against

the pinion shoulders with a suitable sleeve.

B. Install radial bearing lock ring and squeeze ring into

pinion shaft groove with pliers.

C. If new cups are to be installed, press firmly against

pinion bearing cage shoulders.

D. Lubricate bearings and cups with light machine oil.

E. Insert pinion and bearing assembly in pinion cage

and position spacer or spacer combination over

pinion shaft.

F. Press front bearing firmly against spacer.

G. Rotate cage several revolutions to assure normal

bearing contact.

M. Lubricate pinion shaft oil seal and cover outer edge

of seal body with a non-hardening sealing

compound. Press seal against cover shoulder with

seal driver.

N. Install new gasket and bearing cover.

4-17