TM 5-3895-359-14&P

Install exhaust extension on exhaust pipe and air

Service Classification of Oil

cleaner extension on air cleaner.

In addition to the S.A.E. Viscosity grades, oils are also

classified according to severity of engine service. Use

Check steering gear housing and hydraulic brake master

oils classified by the American Petroleum Institute as

cylinder reservoirs. Lift access door on operator's

Service MS, SD or SE. These types of oil are for

platform.

engines performing under unfavorable or severe

operating conditions such as: high speeds, constant

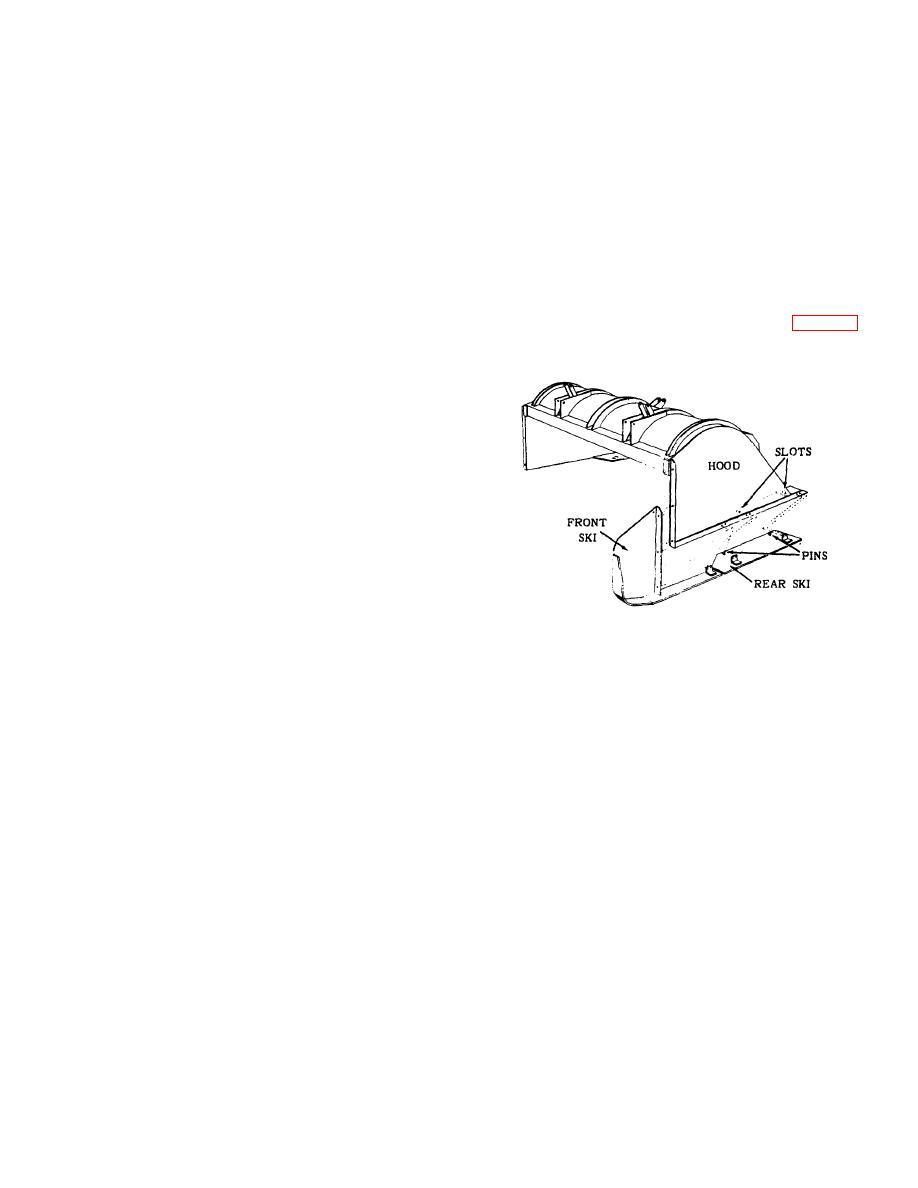

Assemble "skis" to hood bottom. The hood must be

starting and stopping, operating in extreme high or low

raised to do this. Refer to "operating instructions". The

temperatures and excessive idling.

skis consist of two right and left side pieces. The rear

ski pins slip into slots in the hood base, then push or

Fill the air cleaner bowl to level mark with the same

pound ski forward to lock. Secure to hood with the bolts

grade of oil used in the crankcase.

provided. Fit and bolt front ski in place (Fig. 1-7).

Lower hood.

The fuel tank should be filled with a good quality

gasoline free from dirt and water. The capacity of the

tank is approximately 13 gallons.

The gasoline should have an octane rating of at least

90. Low octane gasoline will cause the engine to

detonate, or knock, and if operation is continued under

this condition, cylinders will score, valves will burn,

Be sure that air vent in tank cap is not plugged with dirt,

as this would prevent fuel from flowing to the carburetor.

Preparation and Assembly of Miscellaneous

Equipment

Make a good visual inspection and check of the

machine. Refer to the engine manuals or manual

included in the miscellaneous equipment. Also refer to

Figure 1-7. Hood Assembly

the lubrication chart in this manual for oils and grease

and points of lubrication.

Connect intake hose to pump inlet. Install hose boom in

boom support at the right front of the mixer frame.

One set of extra shear pins and tines are included in the

Hose is supported by means of a loop and spring.

miscellaneous equipment for spares.

Thread hose thru spring loop and attach end of spring to

boom hook.

Remove protective tape from gauges and instruction

plates.

Caution: Do not operate pump without liquid in the

pump body or damage to the pump seal will result.

Install operator's platform seat.

(Refer to

liquid handling system before starting.)

10