TM 5-3895-359-14&P

Keep the cylinder and head fins free from dirt and

Horsepower

chaff. Improper circulation of cooling air will cause

Horsepower specified in the accompanying chart is for

engine to overheat.

an atmospheric temperature of 60 Fahrenheit at sea

level and at a Barometric pressure of 29.92 inches of

Carburetor

mercury.

The proper combustible mixture of gasoline and air is

furnished by a balanced carburetor, giving correct fuel to

For each inch lower the Barometric pressure drops,

air ratios for all speeds and loads.

there will be a loss in horsepower of 3 1/2%.

Ignition System The spark for ignition of the fuel

For each 10 temperature rise there will be a reduction

mixture is furnished by a high tension magneto driven

in horsepower of 1%.

off the timing gears at crankshaft speed. The magneto

distributor rotor turns at half-engine speed.

The

For each 1000 ft. altitude above sea level there will be

magneto is fitted with an impulse coupling, which makes

a reduction in horsepower of 3 1/2%.

possible a powerful spark for easy starting. Also, the

impulse coupling automatically retards the spark for

The friction in new engines cannot be reduced to the

starting, thus eliminating possible kick back from engine

ultimate minimum during the regular block test, but

while cranking.

engines are guaranteed to develop at least 85 per cent

of maximum power when shipped from the factory. The

Lubrication System

power will increase as friction is reduced during the first

A gear type pump supplies oil to four nozzles which

few days of operation. The engine will develop at least

direct oil streams against fins on the connecting rod

95% of maximum horsepower when friction is reduced

caps. Part of the oil enters the rod bearing through

to a minimum.

holes in the rods, and the balance of the oil forms a

spray or mist which lubricates the cylinder walls and

For continuous operation, allow 20% of horsepower

other internal parts of the engine. An external oil line

shown as a safety factor.

from the oil header tube in the crankcase lubricates the

governor and gear train.

Governor

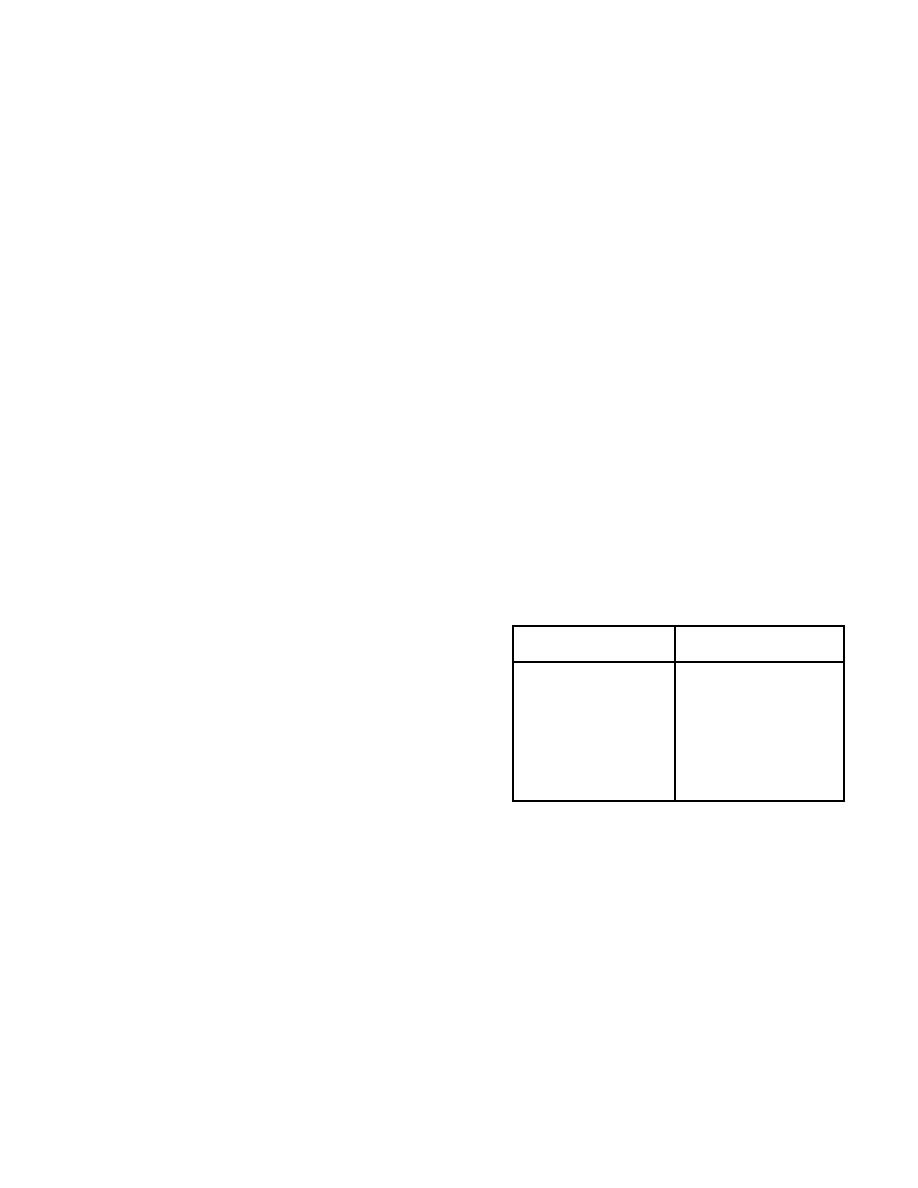

R.P.M.

HORSEPOWER

A governor of the centrifugal flyweight type maintains

the engine speed by varying the throttle opening to suit

1400

17.2

the load imposed upon the engine. These engines are

1600

20.0

equipped with a variable speed control to regulate the

1800

22.5

governed speed of the engine.

2000

24.7

2200

26.5

Rotation

2400

28.0

The rotation of the crankshaft is clockwise when viewing

2600

29.2

the flywheel or cranking end of the engine. This gives

2800

30.0

counter-clockwise rotation when viewing the power

takeoff end of the crankshaft. The flywheel end of the

engine is designated the front end, and the power take-

off end, the rear end of the engine.

7