TM 5-3895-359-14&P

B. Hydraulic pump for crane, tailboard and spray bar

Volumes of liquid up to 500 gallons per minute can be

This pump is a positive displacement, gear type and is

obtained and controlled with extreme accuracy. This

mounted at the rear of the engine off the accessory

system minimizes the number of re-mix passes,

drive opposite the engine tachometer. This pump

advances the travel speeds, which also benefits the tank

supplies oil to the crane and tailboard rams, and to the

trucks resulting in fewer problems that otherwise might

spray bar ram.

be encountered at slower travel speeds.

C. Hydrostatic pump, traction drive Pump is located at

Diesel Engine Principles of Operation

the front of the engine and driven off the engine

crankshaft. The pump is of variable displacement type

The diesel engine is an internal combustion power unit,

and supplies oil under pressure to the hydrostatic motor.

in which the heat of fuel is converted into work in the

cylinder of the engine.

D. Hydrostatic motor, fixed displacement Mounted on

the 2 speed trans. or nose box of the rear axle

In the diesel engine, air alone is compressed in the

differential, motor receives oil from the hydrostatic

cylinder; then, after the air has been compressed, a

pump and drives the rear axle assembly.

charge of fuel is sprayed into the cylinder and ignition is

accomplished by the heat of compression.

E. Oil reservoir The oil reservoir is located to the left

side of the engine dash assembly just below the

The Two-Cycle Principle

hydraulic control valve and supplies and receives oil for

the entire hydraulic system, except power steering.

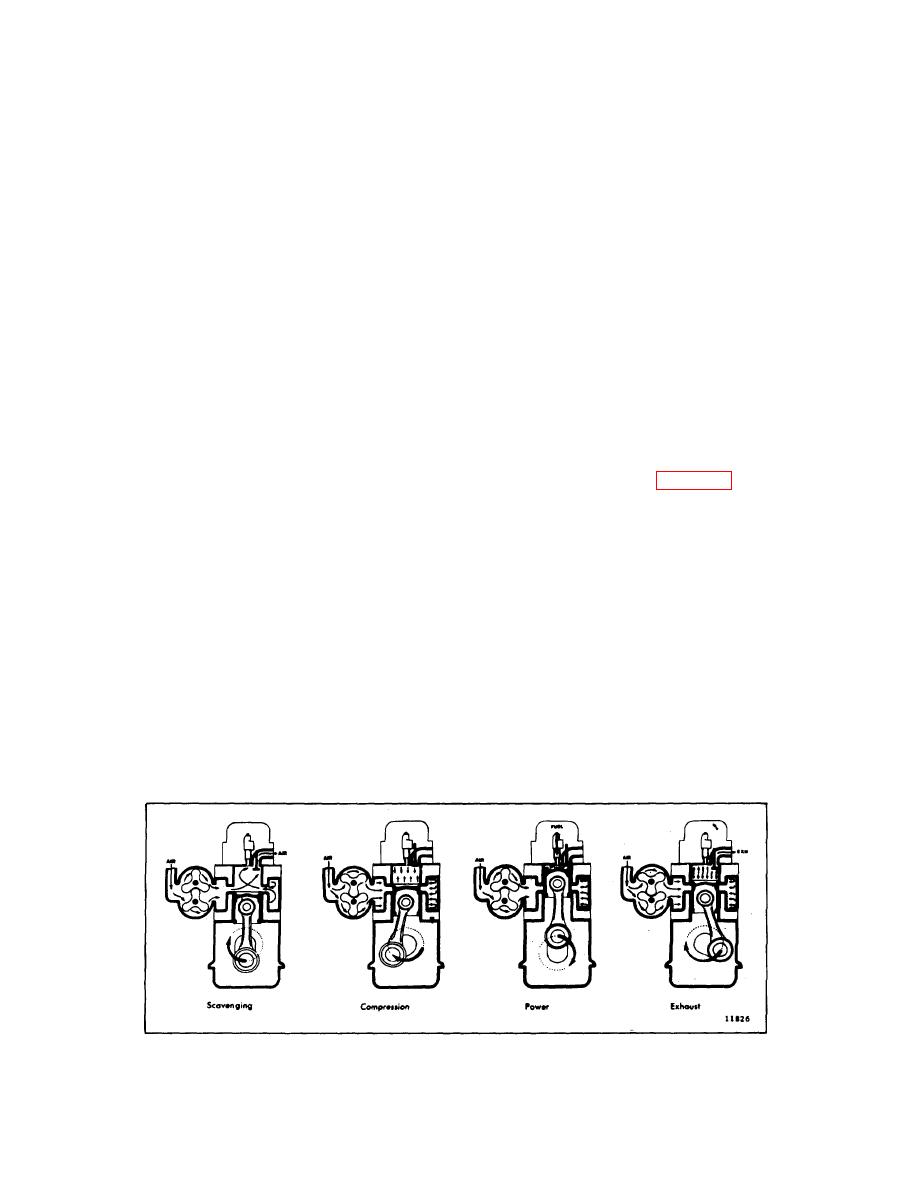

In the two-cycle engine, intake and exhaust take place

during part of the compression and power strokes

F. Hydraulic control valve A two spool dual control

respectively, as shown in Fig. 1-3. In contrast, a four-

valve is used. The valve spools are 4-way type and the

cycle engine requires four piston strokes to complete an

valve has an "open center" or neutral position which

operating cycle; thus, during one half of its operation,

permits the oil to be pumped unrestricted from the

the four-cycle engine functions merely as an air pump.

reservoir thru the pump and control valve back to the

reservoir.

A blower is provided to force air into the cylinders for

expelling the exhaust gases and to supply the cylinders

V.P.I. Fluid Handling System

with fresh air for combustion. The cylinder wall contains

a row of ports that are above the piston when it is at the

The V.P.I.

is an electrically instrumented system

bottom of its stroke. These ports admit the air from the

provisioned with gauges and a liquid control to visually

blower into the cylinder as soon as the rim of the piston

indicate to the operator the performance of the fluid

uncovers the ports (scavenging).

handling system.

The unidirectional flow of air toward the exhaust valves

It operates on an electrical balance principle that

produces a scavenging effect, leaving the cylinders full

integrates the fluid rate of flow with the stabilizer travel

of clean air when the piston again covers the inlet ports.

speed, fulfilling the need for more accurate control and

faster dispersion of liquid, (emulsified asphalt, water or

asphalt cutbacks).

Figure 1-3. Two-Stroke Cycle Operation

3