TM 5-3895-342-12

CHAPTER 2

OPERATING INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF MATERIAL

2-1. Inspecting and Servicing the Equipment

a. Perform the following inspection and services upon receipt of equipment.

(1) Inspect instruments and controls for damage.

(2) Inspect engine thoroughly for evidence of leaks and damaged or disconnected lines and wire.

(3) Inspect all hoses for damage and tight connections.

(4) Open fuel shutoff valve (fig. 3-2) by turning handle counter-clockwise as far as it will go.

(5) Clean around the oil and fuel filler caps before servicing to prevent entry of foreign matter.

WARNING

When filling fuel tank, do not smoke or use an open flame in the immediate area.

Always provide a metal to metal contact between the fuel container and the fuel

tank to prevent a spark being generated as fuel flows over metal surfaces.

(6) Fill fuel tank, and perform lubrication services as instructed in the current lubrication order.

NOTE

When adding fuel to tank before initial operation, fill tank completely full to dilute

the preservative in the tank to prevent clogging of the lines.

b. Perform daily preventive maintenance checks and services. Refer to paragraph 3-4.

2-2. Setting Up Instructions

a. Spotting the Mixer on the Job.

(1) Position mixer so that it sets as level as possible. Locate the mixer convenient to the source of batch

material and the area where the concrete will be used. Allow ample working space around the loading skip and

discharge chute.

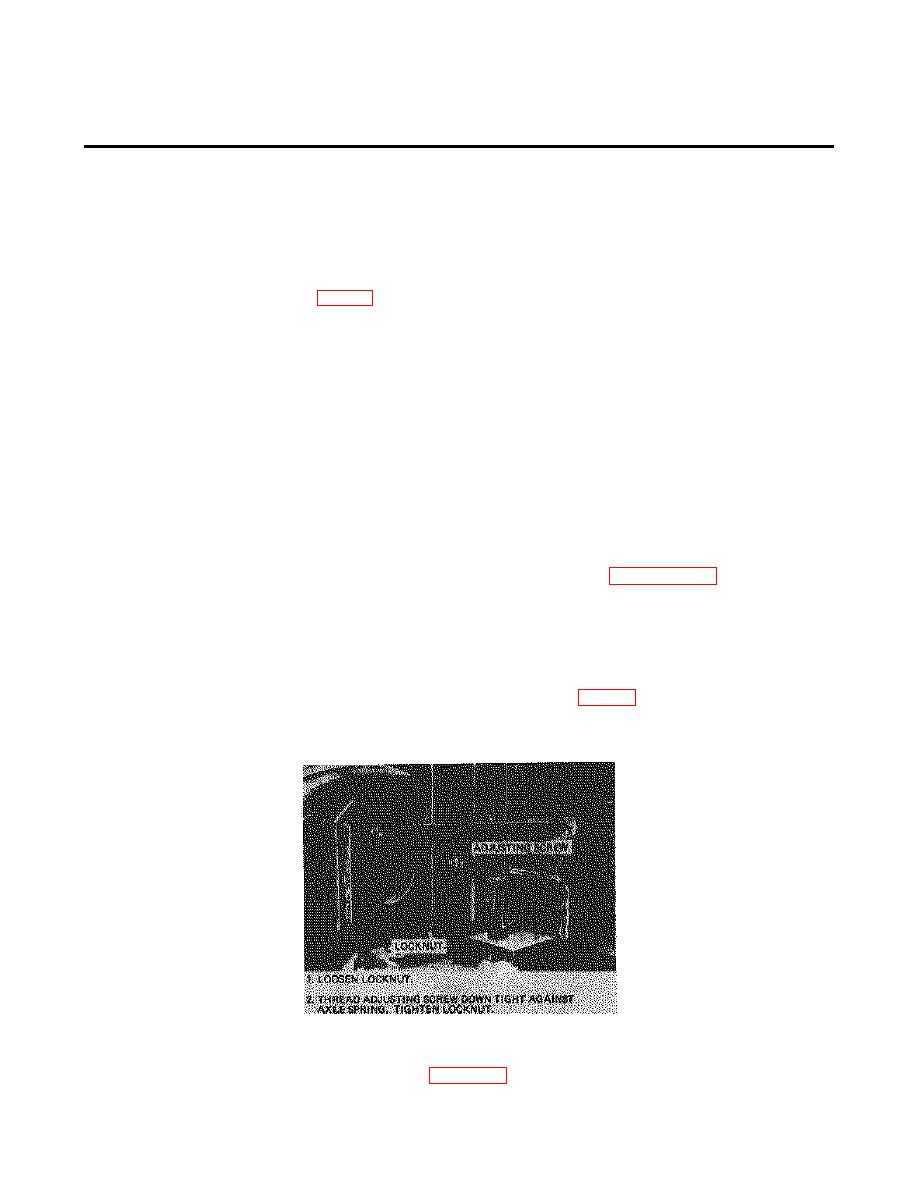

(2) Tighten the adjusting screws at the end of each axle spring (fig. 2-1). This provides four-point K

suspension to the frame and prevents frame torsions when raising the skip. Block the wheels to reduce

vibration and to prevent movement of the mixer.

ME3895-342-12/2-1 C1

Figure 2-1. Axle spring adjusting screw.

b. Disconnect hauling stub as instructed on figure 2-2.

Change 1

2-1