TM 5-3895-369-14

(3)

Clean spray holes on end of valve. Rinse in drycleaning solvent and then in calibration fluid.

(4)

Check opening pressure as follows:

(a)

Install fuel injector to injector gauge pump securely.

(b)

Open valve and operate lever at one stroke per second.

(c)

Read pressure when spray begins. Normal opening pressure is 3160 to 3307 psi (21778 - 22791 kPa).

(5)

Check spray pattern. Pattern must be a straight and steady stream.

(6)

Check leakage as follows:

(a)

Open valve and operate lever.

(b)

Hold pressure 290 psi (1999 kPa).

(c)

No drops must fall within ten seconds.

(7)

Replace fuel injectors failing inspection.

c.

Installation.

Adhesive causes immediate bonding on

contact with eyes, skin, or clothing and also

gives off harmful vapors. Wear protective

goggles and use in well-ventilated area. If

adhesive gets in eyes, try to keep eyes open;

flush eyes with water for 15 minutes and

get immediate medical attention.

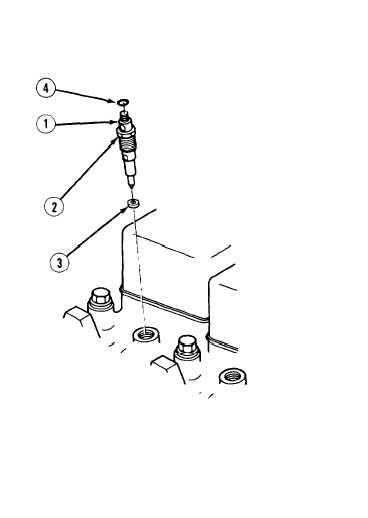

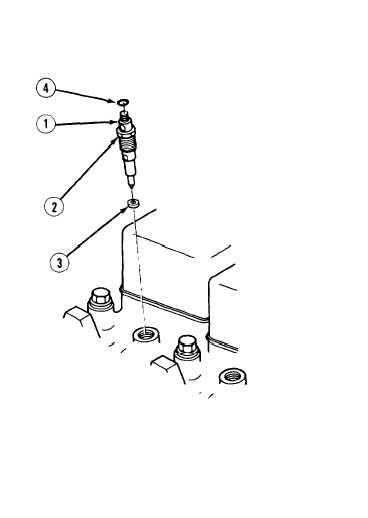

(1)

Apply anti-seize compound on threads of

nut (2).

(2)

Install copper washer (3).

(3)

Install fuel injector (1) and gasket (4).

Tighten nut 44 lb-ft (60 N-m).

NOTE

Follow-on maintenance:

Install injector fuel lines (para 4-47).

Install turbocharger (para 4-44).

Bleed fuel system (para 4-54).

END OF TASK

5-240