TM 5-3895-369-14

(2) Check all parts for damage, cracks, breaks, or deterioration. Replace unserviceable parts.

Do not allow grease or oil to contact brake linings. Linings can absorb grease and oil, causing early

glazing and very poor braking action. Failure to do so could cause serious injury or death to personnel.

(3) Measure thickness of brake linings. If brake linings are less then 1/8 in. (3 mm) thick at thinnest point,

brake shoes must be replaced or repaired (refer to para 5-71, Brake Shoe Repair for repair of secondary

brake shoe).

c. Assembly.

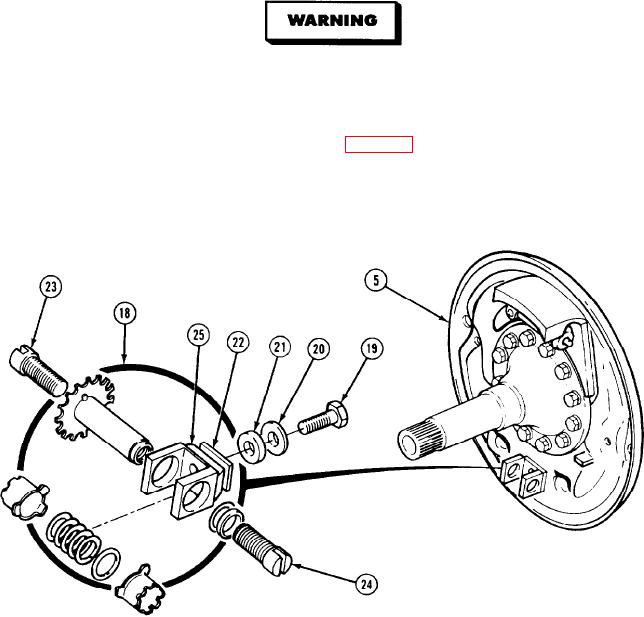

(1) To assemble manual adjuster (18), install assembled hardware and bracket (25) on backing plate (5) with

screw (19), lockwasher (20), washer (21) and shim (22).

(2) Apply lubricant to all points of contact and threads of adjusting screws (24 and 23). Install adjusting

screws in bracket (25). Turn adjusting screws all the way in.

5-419