TM 5-3895-369-14

b. Adjustment.

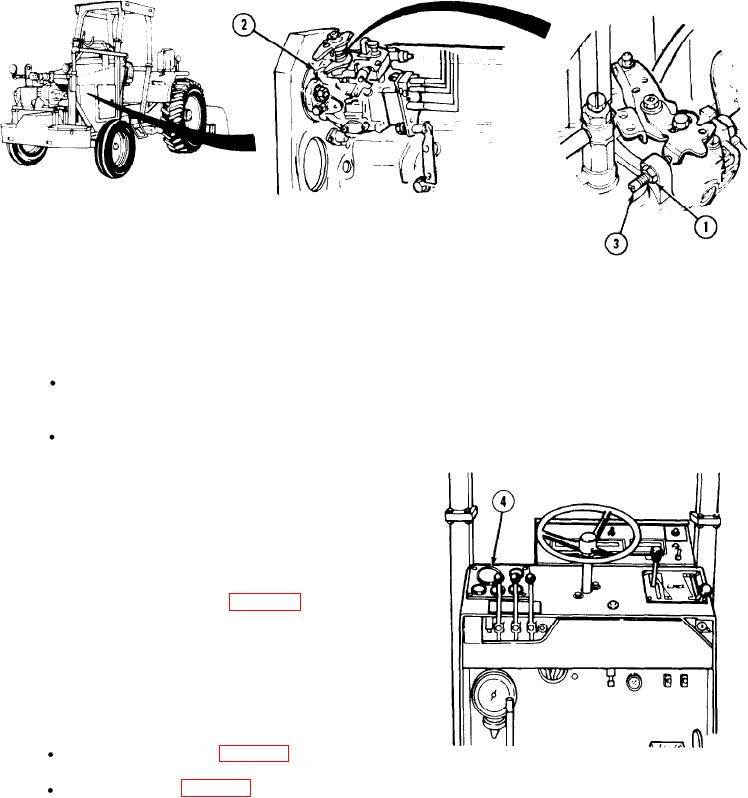

(1) Loosen nut (1) on injection pump (2).

NOTE

To increase RPM, turn idle screw clock-wise. To decrease RPM, turn idle screw to the

left (counterclockwise).

Ensure control lever on injection pump is flush against setscrew for correct adjustment.

(2) While mechanic adjusts idle screw (3),

assistant checks tachometer (4). Adjust idle

screw until idle speed is within 725 to 775

rpm. Tighten nut (1) 4.3 to 6.5 lb-ft

(5.8 - 8.8 Nm).

(3) If idle speed cannot be adjusted to limits,

replace injection pump (para 5-40).

NOTE

Follow-on maintenance:

Close left engine door (para 2-14).

Turn engine off (para 2-10[c]).

END OF TASK

5-237