TM 5-3895-369-14

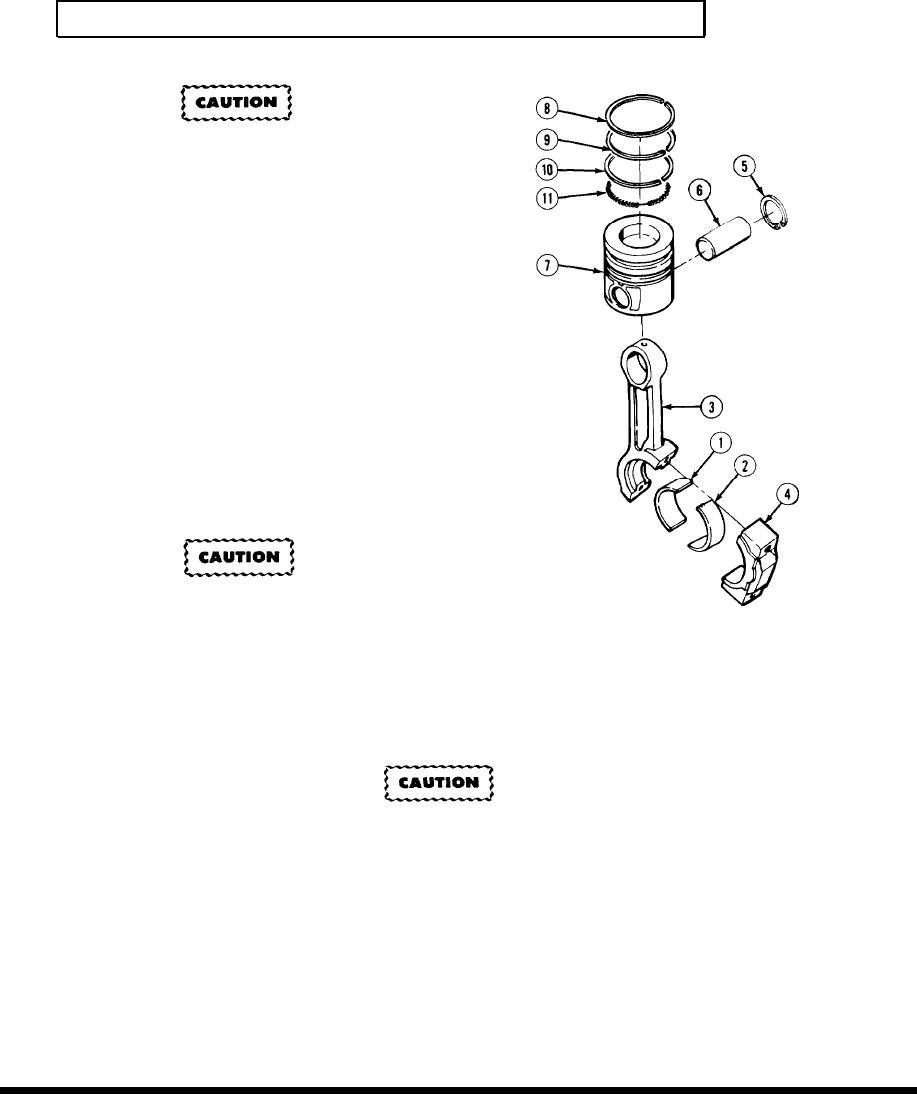

5-22. PISTON AND CONNECTING ROD REPLACEMENT/REPAIR (CONT).

d. Assembly.

Install rings with printed side up.

Improper installation will cause

damage to engine.

End gaps of rings must be 120 apart

from each other. Improper

installation will cause damage to

engine.

(1) Lubricate rings (8,9, and 10) with engine oil.

NOTE

End gap of rings must be at opposite ends

of each other.

(2) Install oil ring expander (11) and oil control

ring (10).

(3) Install intermediate ring (9) and top ring (8).

(4) Install one retaining ring (5) in piston (7).

Markings on piston head and numbers on

connecting rod must be oriented in same

direction for proper assembly. Failure to

do so will result in damage to engine.

(5) Assemble piston (7) and connecting rod (3) securing with wrist pin (6).

(6) Install remaining retaining ring (5).

Do not apply grease on outer diameter of bearing halves or damage may result to bearing halves, related

bearing caps, and crankshaft.

(7) Lubricate 12 bearing halves (1 and 2) with general purpose grease.

(8) Assemble 12 bearings halves (1 and 2) in six connecting rods (3) with six rod caps (4).

5-166