TM 3895-369-14

5-11. CYLINDER BLOCK REPAIR (CONT).

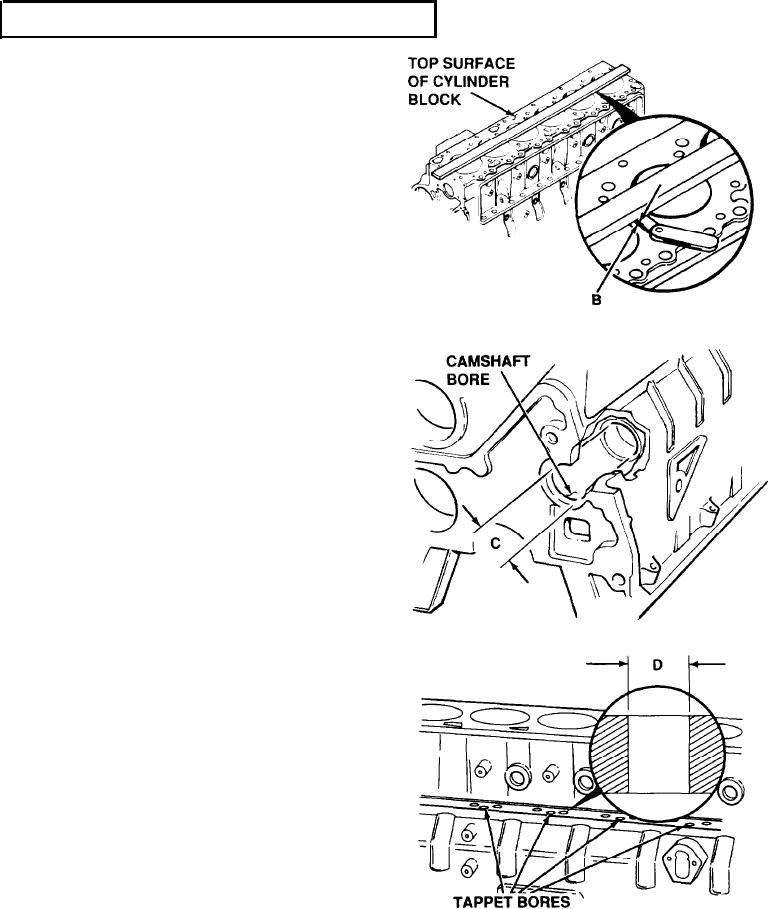

(2) Measure top surface of cylinder block for

flatness at each position B. Variance

measurement must be no greater than

0.002 in. (0.050 mm). If measurement is

beyond limit, replace cylinder block.

(3) Check camshaft bores for scoring and

excessive wear. If severe damage is found,

replace cylinder block.

NOTE

Limits below are for bores 2 and 5 only.

(4) Check camshaft bores at position C.

Normal measurement must be no greater

than 2.1324 in. (54.164 mm). If

measurement is beyond limit, replace

cylinder block.

(5) Check tappet bores for scoring or excessive

wear. If damaged is excessive, replace

cylinder block.

(6) Measure tappet bores at position D. Normal

measurement is 0.630 to 0.632 in. (16.0 -

16.055 mm). If measurement is less than

limit, ream out tappet bores to size. If

measurement is greater than limit, replace

cylinder block.

5-120