TM 5-3895-369-14

4-165. SPRAY BAR ASSEMBLY REPLACEMENT/REPAIR (CONT).

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use only with effective

chip guarding and personal protective equipment (goggles/shield, gloves, etc).

(2) Use clean lint-free cloth or compressed air to dry all metal parts.

(3) Clean all gasket material from spray bar.

(4) Check spray bar for cracks, breaks, or other damage.

(5) Check shutoff bar for bends, cracks, or other damage.

d. Assembly.

Sealant causes immediate bonding on

contact with eyes, skin, or clothing and also

gives off harmful vapors. Wear protective

goggles and use in well-ventilated area. If

adhesive gets in eyes, try to keep eyes open;

flush eyes with water for 15 minutes and

get immediate medical attention.

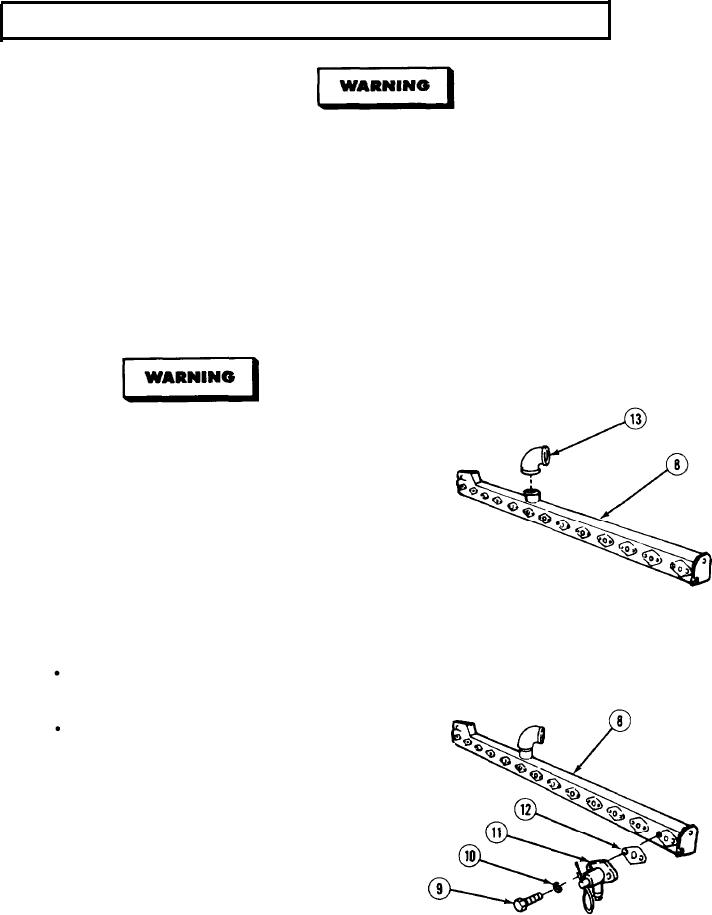

(1) Apply hydraulic thread sealant to threads of

elbow (13) and install elbow (13) on spray

bar (8).

NOTE

Apply small coating of silicone sealant

to gaskets.

Apply thread sealant to threads of

screws. Do not overtighten screws.

(2) Install 21 gaskets (12) and spray valve

assemblies (11) on spray bar (8) with

42 lockwashers (10) and screws (9).

4-534