TM 5-3895-359-14&P

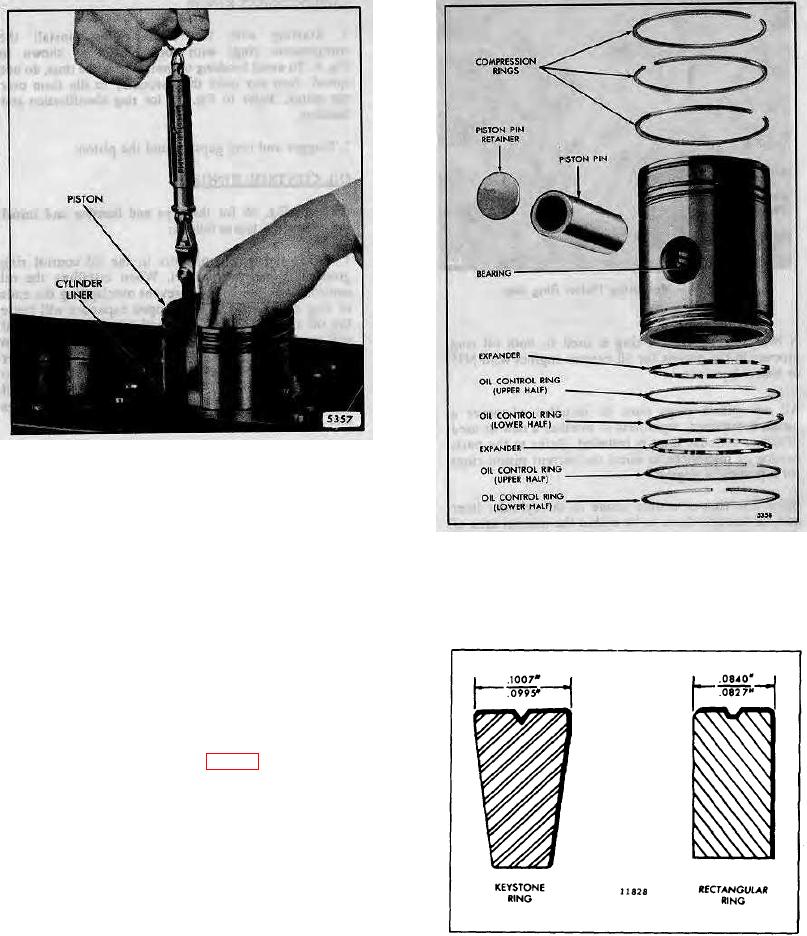

Fig. 11 - Measuring Piston-to-Liner Clearance

using Tool J 5438-01

.001" greater than the thickness of the feeler gage used,

i.e., a .004" feeler gage will indicate a clearance of .005"

when it is withdrawn with a pull of six pounds. The

Fig. 12 - Piston Ring Location (Non-

feeler gage must be perfectly flat and free of nicks and

Turbocharged Engine)

bends.

the tapered fire ring groove are available for service.

If any bind occurs between the piston and the liner,

examine the piston and liner for burrs. Remove burrs

with a fine hone (a flat one is preferable) and recheck

the clearance.

Fitting Piston Rings

Each piston is fitted with a fire ring, two compression

rings and two oil control rings (Fig. 12).

The top (fire) ring and the upper compression ring

(second groove) are pre-stressed. Both are identified by

a small indentation mark on the top side.

NOTE: The current piston crowns (18.7: 1 and

17: 1 compression ratio) have a tapered fire ring

groove. To conform with this change, a tapered

fire ring (Fig. 13) must be used. The former

piston crown (17: 1 compression ratio) had a

rectangular fire ring groove. Only pistons with

Fig. 13 Comparison of Fire Rings

10-2-83