TM 5-3895-359-14&P

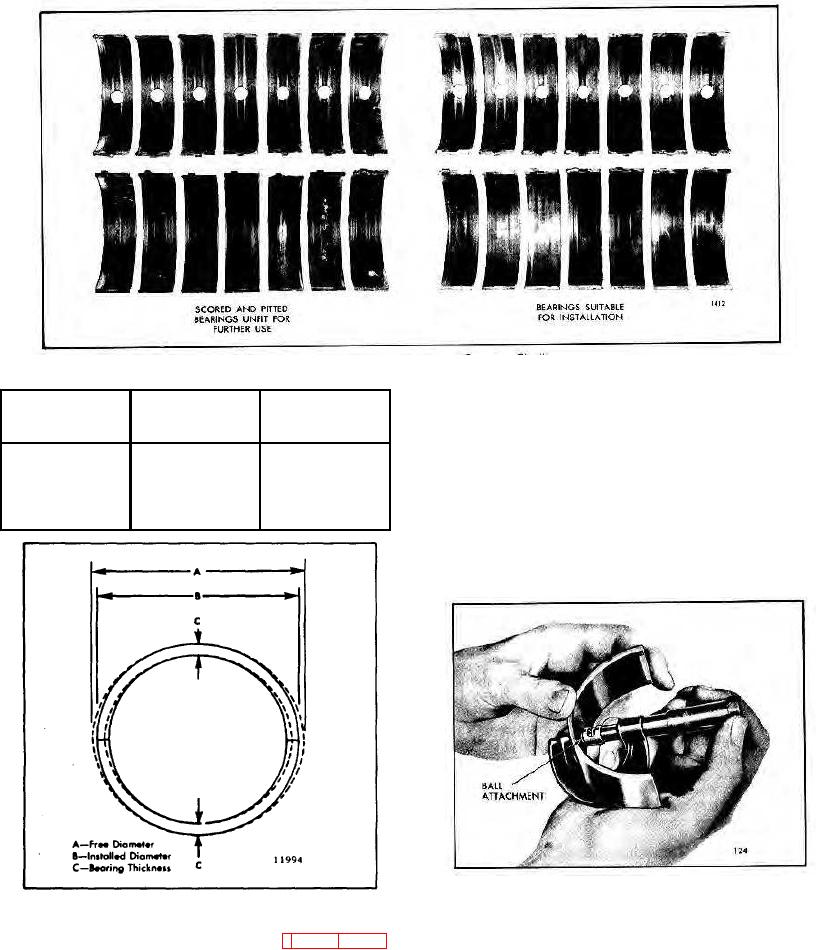

Fig. 5. Comparison of Main Bearing Shells Minimum

bearing shell thickness will be the total thickness of the

Minimum

steel ball in the tool and the bearing shell, less the

Bearing

Bearing

Worn

diameter of the ball. This is the only practical method

Size

Thickness

Thickness

for measuring the bearing thickness, unless a special

Standard

.1548"/.1533"

.1530"

micrometer is available for this purpose. The minimum

.002" Undersize

.1558"/. 1563'

.1540"

thickness of a worn standard main bearing shell is .1530

.010" Undersize

.1598"/.1603"

.1580"

" and, if any of the bearing shells are thinner than this

.020" Undersize

.1648"/.1653"

.1630"

dimension, replace all of the bearing shells. A new

.030" Undersize

.1698"/. 1703"

.1680"

standard bearing shell has a thickness of .1548 " to

.1553 ". Refer to Table 1.

In addition to the thickness measurement, check the

clearance between the main bearings and the

Fig. 7. Measuring Thickness of Bearing Shell

Fig. 6. Main Bearing Measurements

Measure the thickness of the bearing shells at point "C",

90 from the parting line, as shown in Figs. 6 and 7.

Tool J 4757, placed between the bearing shell and a

micrometer, will give an accurate measurement. The

10-2-61