TM 5-3895-359-14&P

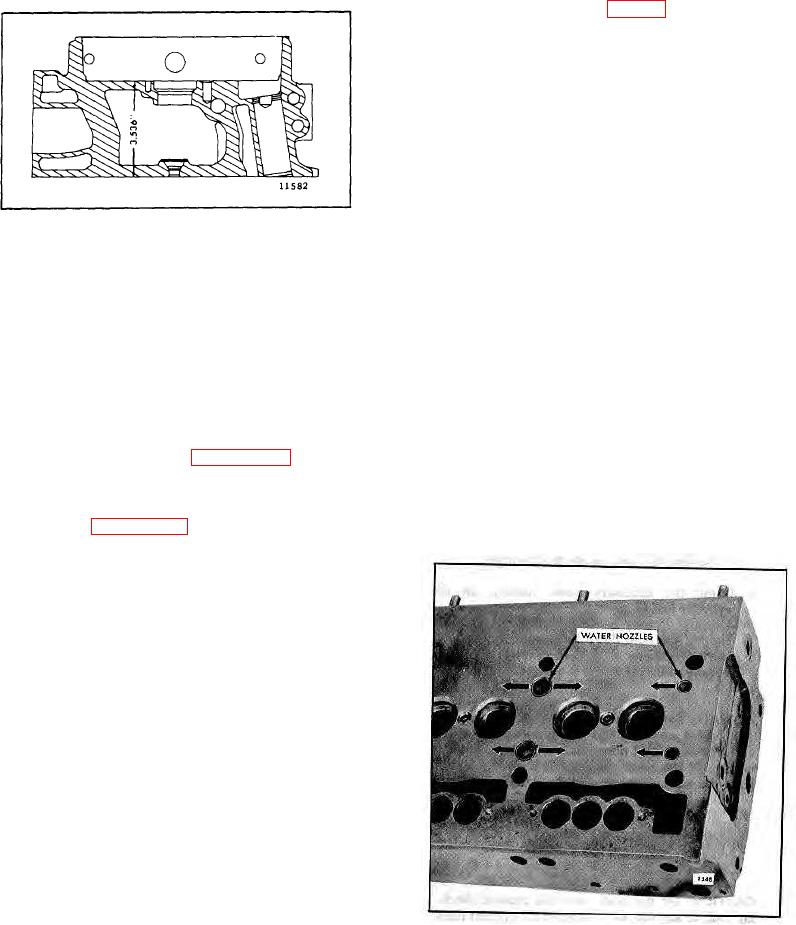

two valve cylinder head (Fig. 10). Install the 1/2"

diameter nozzles at the ends of the cylinder head with

their openings toward the center of the engine. Press

the nozzles flush to .0312" recessed below the surface

of the cylinder head.

d.

Check to make sure the nozzles fit tight.

If necessary. use a wood plug or other suitable tool to

expand the nozzles, or tin the outside diameter with

solder to provide a tight fit. If solder is used, make sure

the orifices in the nozzles are not closed with solder.

7. Replace broken or damaged studs. Apply sealant to

Fig. 9- Minimum Distance Between Top and Bottom

the threads of new studs and drive them to 10-25 lb-ft

Faces of Cylinder Head

(14-34 Nm) torque (water manifold cover studs) or to 25-

NOTE: When a cylinder head has been

refaced, critical dimensions such as the

8. Inspect all other components removed from the

protrusion of valve seat inserts, exhaust

cylinder head.

valves, injector tubes and injector spray

tips must be checked and corrected.

If a service replacement cylinder head is to be installed,

The push rods must also be adjusted to

it must be thoroughly cleaned of all rust preventive

prevent the exhaust valves from striking

compound, particularly inside the integral fuel manifolds,

the pistons after the cylinder head is

before installing the plugs.

A simple method of

reinstalled in the engine.

removing the rust preventive compound is to immerse

the head in a mineral spirits based solvent or fuel oil,

3. Install new injector tubes (Page 10-3-25) if the old

then scrub the head and go through all of the openings

tubes leaked or the cylinder head was refaced.

with a soft bristle brush. A suitable brush for cleaning

the various passages in the head can be made by

4. Inspect the exhaust valve seat inserts and valve

attaching a 1/8" diameter brass rod to brush J 8152.

guides (refer to Page 10-2-40).

After cleaning, dry the cylinder head with compressed

air.

5. Inspect the cam follower bores in the cylinder head

for scoring or wear. Light score marks may be cleaned

up with crocus cloth wet with fuel oil. Measure the bore

diameters with a telescope gage and micrometer and

record the readings. Measure the diameter of the cam

followers with a micrometer. Record and compare the

readings of the followers and bores to determine the

cam followers-to-bore clearances. The clearance must

not exceed .006" with used parts (refer to Page 10-2-

136 for specifications). If the bores are excessively

scored or worn, replace the cylinder head.

6. Check the water hole nozzles to be sure they are not

loose. If necessary, replace the nozzles as follows:

a. Remove the old nozzles.

b. Make sure the water inlet ports in the cylinder

head are clean and free of scale. The water

holes at each end of the head may be cleaned

up with a 1/2" drill and the intermediate holes

Fig. 10. Correct Installation of Water Nozzles in

may be cleaned up with a 13/16" drill. Break the

edges of the holes slightly.

Two-Valve Cylinder Head

c.

Press the nozzles in place with the nozzle

openings parallel to the longitudinal center line of the

10-2-24