TM 5-3895-359-14&P

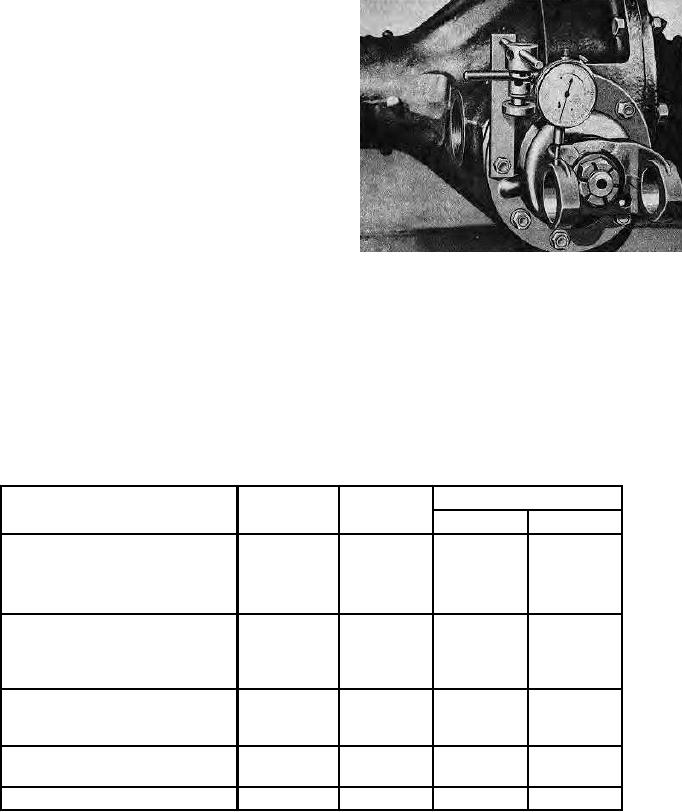

CHECK AND ADJUST GEAR LASH

A. Install differential and gear assembly and

assemble cover using new gasket with six bolts

equally spaced. Tighten to specified torque.

B. Check gear lash with dial indicator on universal

joint yoke 2" from pinion shaft center. An

indicator reading of between .013" and .033" will

show the recommended backlash of between

.006" and .012" is present in the gear set.

C. Transpose spacers used in both the case and

cover, decreasing the thickness of the spacer

used on the side in the direction which the gear

is to be moved and increasing the thickness of

the opposite spacer exactly the same amount as

required to obtain the correct gear lash.

D. Install remaining bolts, washers and nuts in

housing assembly and tighten all nuts in bolt

circle to specified torque.

LUBRICATION

Fill axle to correct level with specified

lubricant and lubricate universal joint.

Refer to lubrication chart on page 15-1.

TORQUE SPECIFICATIONS

TORQUE-LB. FT.

DIAM-

NO.

LOCATION

ETER

THREADS

Min.

Max.

Cover to case bolt nuts

3/8"

16

27

35

3/8"

24

31

39

7/16"

20

42

54

"

20

75

96

Pinion cage cap screws

3/8"

16

27

35

and stud nuts

3/8"

24

31

39

7/16"

20

42

54

9/16"

12

94

120

Differential case bolt nuts

3/8"

16

33

43

and cap screws

"

13

81

104

"

20

92

118

Pinion shaft nuts

7/8"

20

175

200

1"

20

300

400

Gear to case cap screws

3/8"

24

38

49

Torques given apply to parts coated with machine oil; for dry (or "as received") parts

Nuts on studs to use same torque as for driving the stud.

5-19