TM 5-3895-359-14&P

ENGINE SMOKES AND RUNS RICH

CLEANING Wash all parts in a mild solvent or fuel.

Blow air through orifices (holes) and channels in throttle

Dirty air filter: Clean per instructions.

body and fuel bowl. Do not probe with any sharp tools

Improper adjustment: Set Idle Needle 1 1/8 turns

which might damage small metering holes.

open from seat. Refer to Adjustment Instruction, page

REASSEMBLY Replace all worn or damaged parts use

14-15.

all new gaskets.

Bowl to body gasket leaks:

Tighten securely, or

Note; Body Gasket (18) is put on before float is

replace.

assembled, and round opening in gasket fits into groove

Air vent in carburetor plugged: Remove fuel bowl

of Venturi (11).

and idle needle. Clean air and idle channels thoroughly

Be sure that Notch in Venturi is facing toward float

with compressed air.

needle valve this is clearance for Main nozzle in throttle

ENGINE RUNS LEAN Improper adjustment: Set Idle

body.

Needle 1 1/8 turns open from seat.

Refer to

Assemble Throttle Valve (8) and Choke Valve (25) with

Adjustment Instructions, page 14-15.

part numbers facing to the outside, when valves are in

Idle holes plugged. Dirt in fuel delivery channels:

the closed position.

Remove fuel bowl and idle needle. Clean thoroughly

IMPORTANT: Be careful in tightening brass screws and

with compressed air.

fittings, so as not to strip threads and screw driver slots.

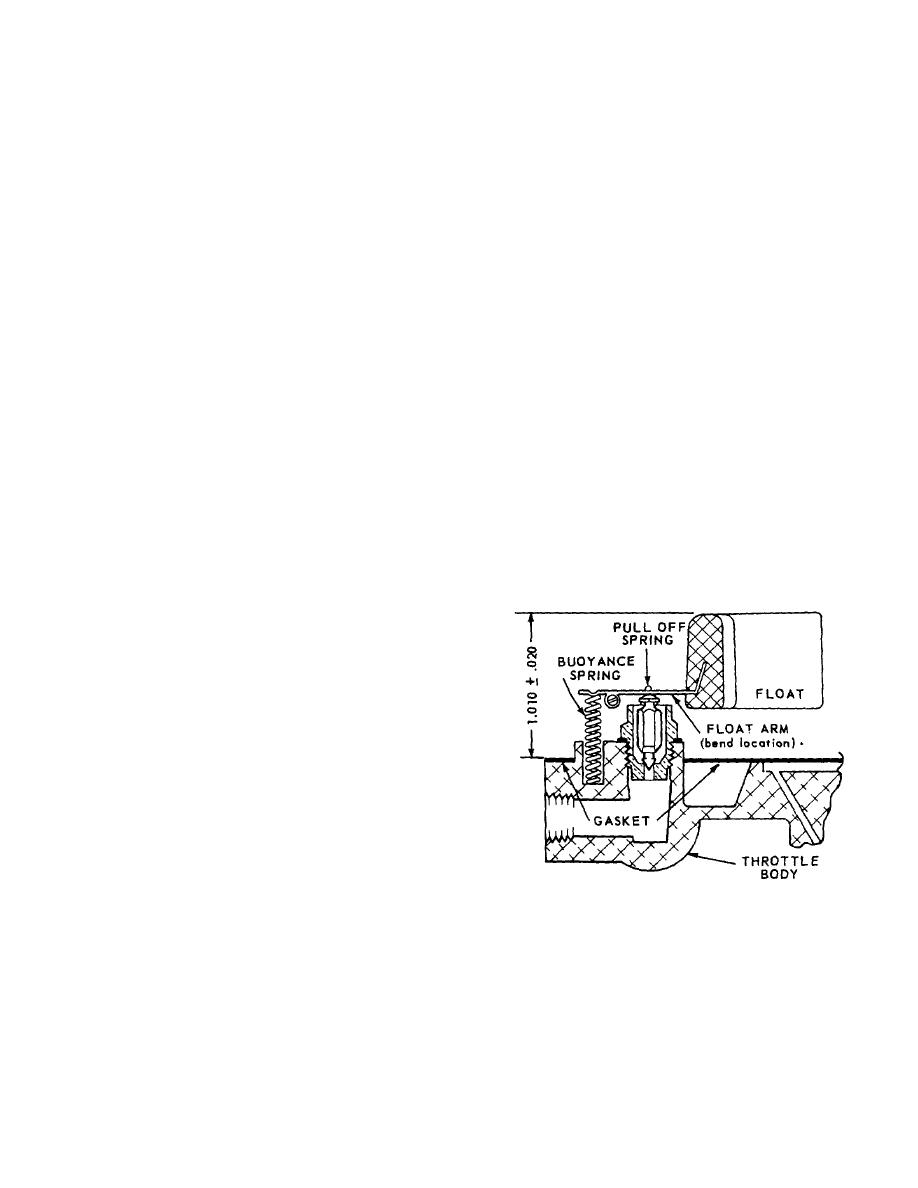

Low fuel level: See Fig.

30 and Float Setting

Tighten firmly but not excessively.

Instructions, page 14-15.

Valve Seat (16) 40 to 50 inch pounds torque Main Jet

Fuel filter plugged: Remove and clean.

(22) 50 to 60 inch pounds torque FLOAT SETTING,

ENGINE STARTS HARD Improper adjustment: Set

Fig. 30 With fuel bowl removed and float assembly in

Idle Needle 1 1/8 turns open from seat. Refer to

place, turn throttle body upside down so that float

Adjustment Instructions, page 14-15.

assembly is on top.

No fuel in carburetor: Check carburetor drain plug.

Check float height with a depth gauge. Setting should

Clean tank, filter and carburetor. Check fuel lines for

be 1.010 inch .020 above bowl gasket. If necessary,

obstructions, and test fuel pump.

bend float arm (at float), to obtain correct height.

Choke valve not closing:

Check linkage for proper

travel.

GOVERNOR SURGE Governor sticking:

Check

linkage for binding.

Throttle shaft and valve binding:

Remove and

replace.

shaft if worn. Clean carburetor body and reassemble

throttle shaft.

DISASSEMBLY Before disassembling: Clean outside

of carburetor from all foreign material.

IMPORTANT: When cleaning a completely assembled

carburetor do not blow with compressed air, you may

collapse the float.

For a complete disassembly, follow the sequence of part

reference numbers in the carburetor exploded view, Fig.

FIGURE 30. FLOAT SETTING

31. Nozzle Ref. 9, Fig. 29 is not removable.

IMPORTANT: Before removing Throttle and Choke

ADJUSTMENTS, Fig. 29 Turn Idle speed screw (5),

levers, note their position and location.

Optional

Fig. 31, in until throttle valve is slightly open. With

mounting is available and may differ from exploded

engine warmed up and running, turn adjusting screw in

view illustration.

or out as required to obtain desired low idle speed (1000

to 1200 r.p.m.).

14-15