TM 5-3895-359-14&P

period of about 10 minutes will be required before the

cartridge every oil change.

Be sure that your

switch has cooled off sufficiently to re-start the engine.

replacement is a Wisconsin Micro-Fine filter.

An overheated engine will score the cylinder walls, burn

6. Do not allow shrouding to become damaged or

out connecting rod and crankshaft bearings, also warp

badly dented as this will retard air flow.

pistons and valves. The cause of the overheating

Never operate engine with air shrouding

condition will have to be remedied before the engine is

removed. This will retard air cooling.

re-started.

See Engine Overheats paragraph in

Troubles, Causes and Remedies section Service Kit is

Always keep all parts of the engine clean.

available see parts list section.

This will prolong engine life, and give more

satisfactory operation.

KEEPING ENGINE CLEAN

Every 4 to 8 hours, depending on dust conditions,

check air cleaner and change oil. See Page 14-1.

This engine is cooled by blasts of air which must be

allowed to circulate all around the cylinders and cylinder

heads to properly cool the engine and thereby keep it in

full mark on oil gauge sabre, but no more.

good running condition. If dust, dirt or chaff is

allowed to collect in the cylinder shrouding or in the

TROUBLES CAUSES AND REMEDIES

V between the cylinders, it will retard the flow of air

and cause the engine to overheat. Keep flywheel

Three prime requisites are essential to starting and

screen and rotating screen clean, so as not to restrict

maintaining satisfactory operation of gasoline engines.

the intake of cooling air.

They are:

1. A proper fuel mixture in the cylinder.

1. Remove covers frequently and clean out all

2. Good compression in the cylinder.

dust, dirt and chaff. Be sure to replace covers.

3. Good spark, properly timed, to ignite the mixture.

If all three of these conditions do not exist, the engine

cannot be started. There are other factors which will

contribute to hard starting; such as, too heavy a load for

the engine to turn over at a low starting speed, a long

exhaust pipe with high back pressure, etc. These

conditions may affect the starting, but do not necessarily

mean that the engine is improperly adjusted.

As a guide to locating any difficulties which might arise,

the following causes are listed under the three headings:

Fuel Mixture, Compression, and Ignition.

In each case, the causes of trouble are given in the

order in which they are most apt to occur. In many

cases the remedy is apparent, and in such cases no

further remedies are suggested.

STARTING DIFFICULTIES

FUEL MIXTURE

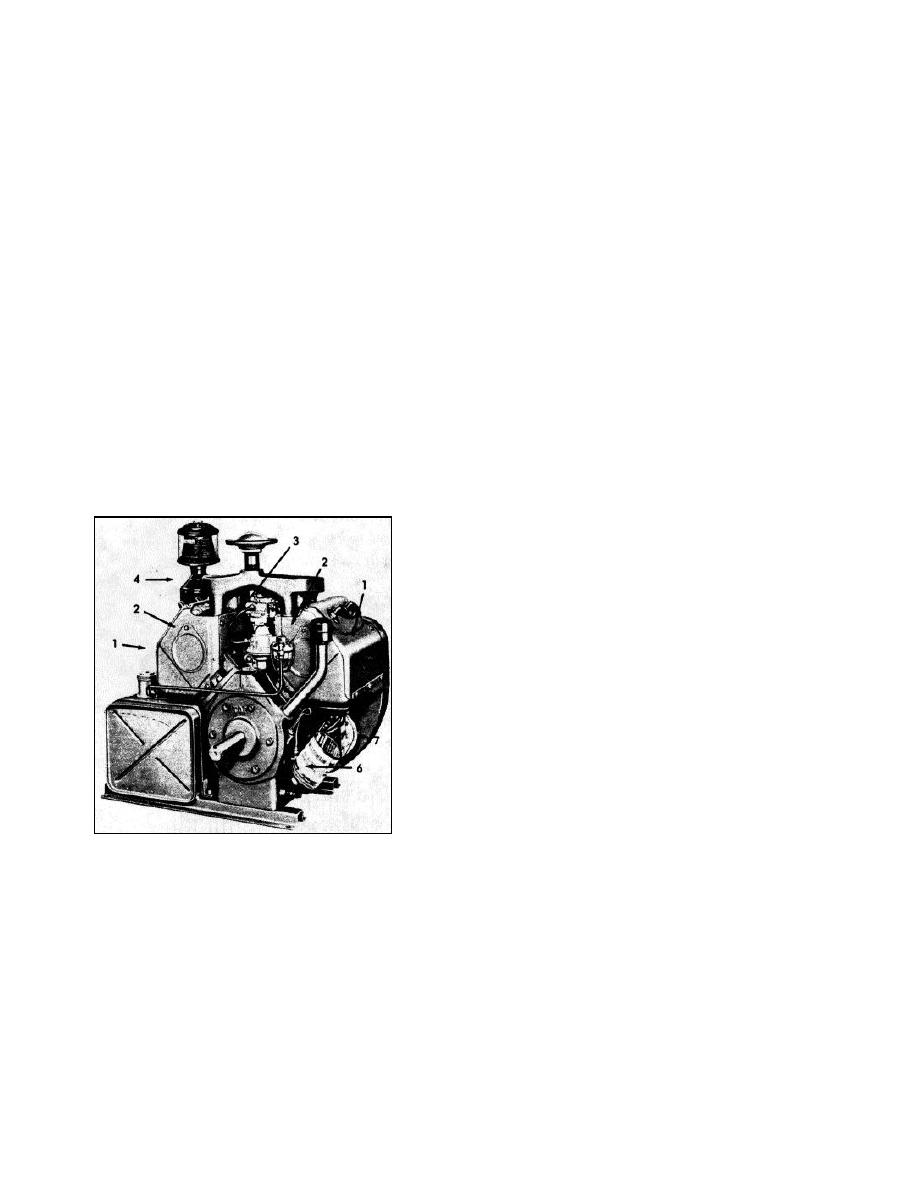

FIGURE 9

221526C

No fuel in tank or fuel shut-off valve closed.

2.

Open these covers frequently and clean out all

Fuel pump diaphragm worn out, so pump does not

dust and chaff. Be sure to close covers.

supply carburetor with fuel.

3.

Keep this space between cylinders free of dust

and chaff.

Carburetor not choked sufficiently, especially if engine is

cold.

4.

Read instructions on this air cleaner regarding

its care. This is important. The entire air

cleaner should be removed from the engine at

Water, dirt, or gum in gasoline interfering with free flow

least once a year, and washed in a cleaning

of fuel to carburetor.

fluid to clean out dirt gathered in the back fire

trap in the top part of the air cleaner.

5.

Replace the oil filter cartridge every other oil

change. If operating conditions are extremely

dusty replace TM 5-3895-359-14&P

14-5