TM 5-3895-359-14&P

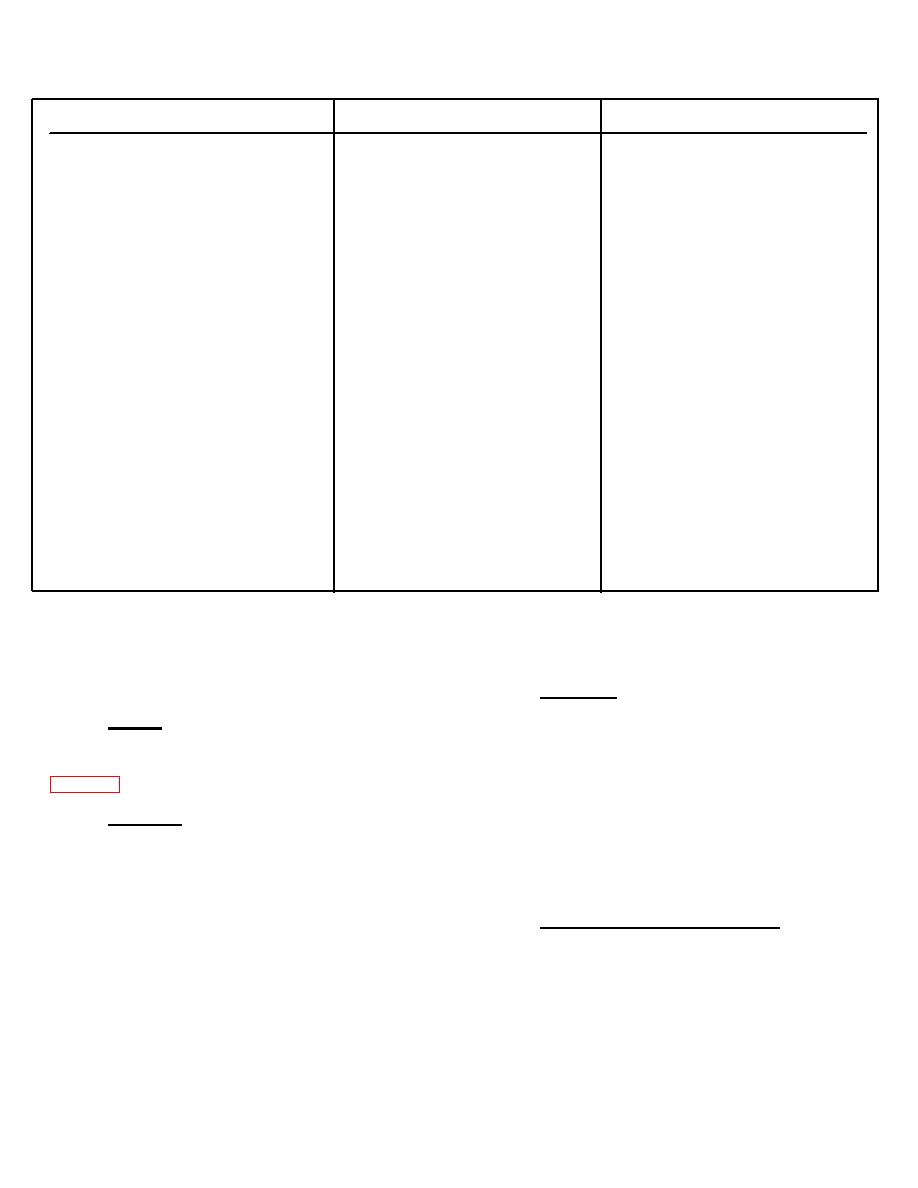

TABLE II. - TROUBLE SHOOTING CHART (CONTINUED)

TROUBLE

PROBABLE CAUSE

REMEDY

PUMP NOT DELIVERING OIL

Vane or vanes stick in rotor slots.

Disassemble pump. Examine rotor

(CONTINUED)

slots for dirt, grime or small metal

chips. Clean rotor and vanes in a

good grade solvent (mineral oil or

kerosene). Reassemble parts and

check for free vane movement.

Oil viscosity too heavy to pick up

Use fluid of the proper viscosity.

prime.

NOISY PUMP OPERATION

Pump intake partially blocked.

Drain system completely. Flush to

clear pump passages. Flush and

refill system with clean oil as per

prescribed recommendations.

Air vent for oil tank clogged or

Remove filler cap and clean -air

dirty strainer.

vent slot. Check strainer in tank

for clogged condition. Drain, flush

and add clean oil to system.

Air being drawn into pump return

Pump must receive air-free oil or

connection.

pump will be noisy. Drain system.

Tighten all hose connections. Clean

or replace filter. Add clean oil of

the proper viscosity.

Leaking shaft seal.

Check pump shaft seal and replace

if sealing lip has been damaged.

Check for scoring of shaft at seal

contact area. Replace faulty shaft.

OVERHAUL

c. Remove the pressure plate. Note the

position of the pump ring for reassembly. Pull out the

A. DISASSEMBLY

ring locating pins and remove the ring. Remove the

vanes from the rotor slots and slide the rotor off the

CAUTION: Before removing a unit to be serviced, be

driveshaft. Remove the body "O" ring.

sure it is not under pressure.

3. Shaft End - Remove the driveshaft key.

Remove the bearing retaining snapring and gently tap

the splined end of the shaft to remove the shaft and the

1. General - Use a puller to remove shaft gears or

outboard bearing. Support the outboard bearing inner

race in an arbor press and press out the shaft. Remove

During disassembly, pay special attention to

the seal from the body with a hooked tool. Remove the

identification of parts for proper reassembly. Refer to

inboard bearing from the shaft end of the body with a

bearing puller or by tapping it out from the cover end.

discussion.

2. Cover End - Clamp the pump mounting flange

B. INSPECTION, REPAIR AND REPLACEMENT

in a vise. Be certain to use protective jaws.

a. Reservoir Remove the tank cover screw,

Discard all used seals and gaskets. Wash all parts in a

lockwasher, washer, guide and guide gasket. Lift off the

clean mineral oil solvent and place them on a clean, lint-

tank cover and gasket and remove the tank screws,

free surface for inspection. Soak new seals and "O"

tank, gaskets and spacers.

rings in hydraulic fluid prior to reassembly.

b. Remove the cover screws and separate

1. Cartridge, Body and Pressure Plate - Inspect all

the cover from the pump. Remove the control valve

wearing surfaces for scoring. Light scoring can be

subassembly and spring and the cover "0" ring.

removed from the body and wear plate with crocus cloth

or by stoning or lapping.

NOTE: Control valve subassemblies are preset and

Inspect the vanes for wear. Vanes must not

tested by Vickers and should not be disassembled. If

have excessive play in the rotor slots or burred edges.

any part is defective, the complete subassembly should

Replace the vanes if they are defective. Check each

be replaced.

rotor slot for sticky vanes or for wear. Vanes should

drop in the rotor slots from their own weight when both

the rotor and vanes are dry.

11-5